Duplex stainless steel and method for producing same

A technology of duplex stainless steel and manufacturing method, which is applied in the direction of manufacturing tools, furnaces, heat treatment equipment, etc., to achieve the effect of cheap manufacturing and excellent resistance to carbon dioxide gas corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

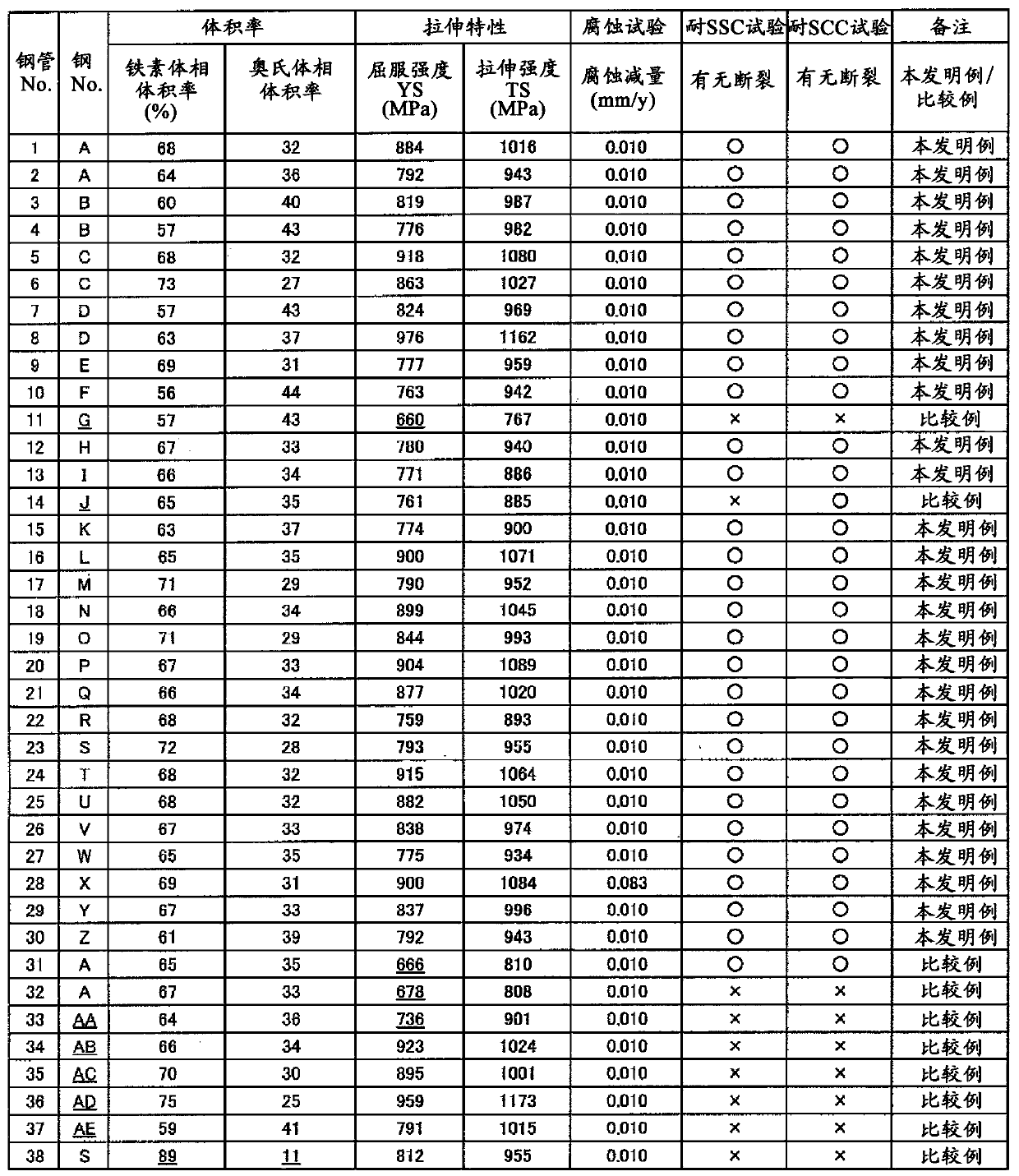

[0125] Hereinafter, the present invention will be described by way of examples. In addition, this invention is not limited to the following Example.

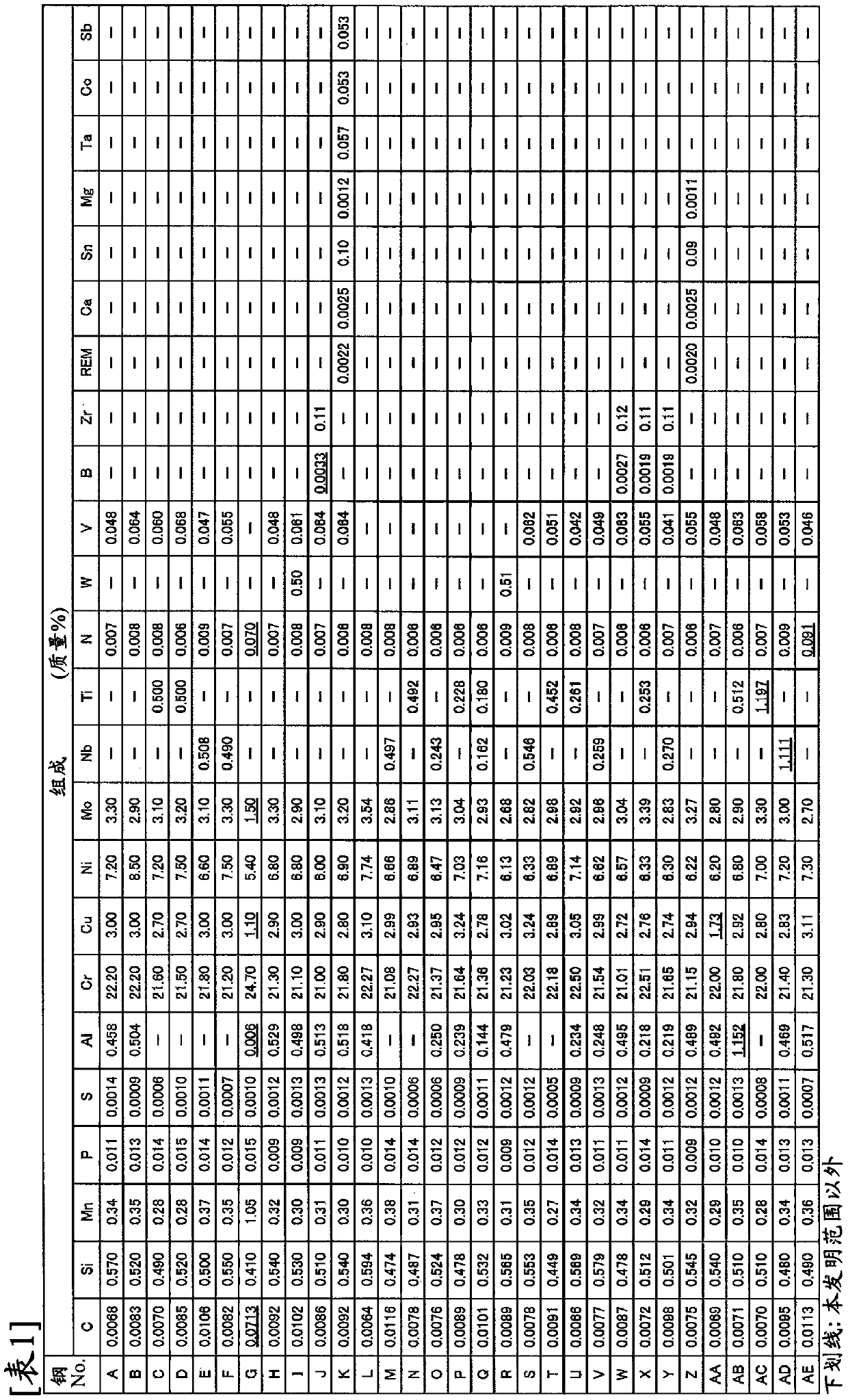

[0126] In this example, the molten steel with the composition shown in Table 1 was smelted using a converter, cast into a billet (steel pipe raw material) by continuous casting, and the steel pipe raw material was heated at 1150 to 1250°C, and then, by using a heating model The hot working of the seamless rolling mill was performed to produce a seamless steel pipe having an outer diameter of 83.8 mm x a wall thickness of 12.7 mm. It should be noted that the seamless steel pipe was air-cooled after the pipe production.

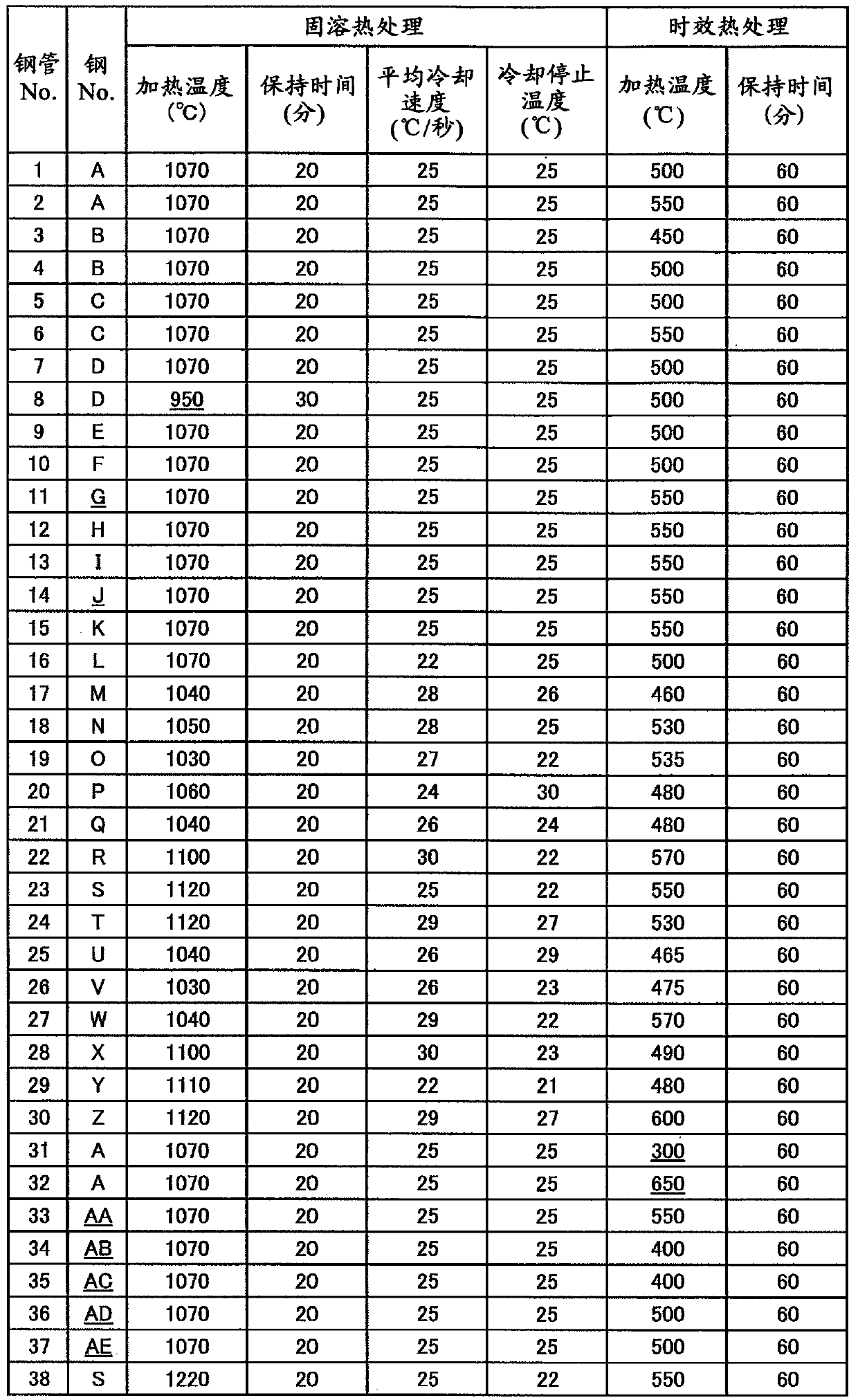

[0127] The obtained seamless steel pipes were subjected to a solution heat treatment in which heating was performed under the conditions shown in Table 2, followed by cooling. Then, an aging heat treatment of heating under the conditions shown in Table 2 and then air cooling was further performed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com