Functional oil microcapsule containing chia seed gum and preparation method thereof

A technology of functional oil and microcapsule, which is applied in the field of functional oil microcapsule and its preparation method, can solve the problems of low oral utilization rate of resistant starch, easy destruction of nutrients, easy oxidation of functional oil, etc., and achieve good fluidity, Good thermal stability and high embedding rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

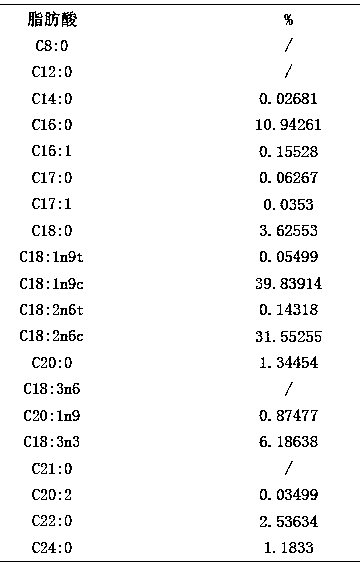

[0036] The preparation process of the core material: first add 25g of chia seed oil into the container, then add 10g of olive oil, and finally add 65g of peanut oil, mix thoroughly; make liquid oil, pack and store at an appropriate temperature.

[0037] Preparation process of functional oil microcapsules containing chia seed gum: Weigh 10g sodium caseinate, 15.95g chia seed gum, 43.7g high amylose corn starch, 0.87g monoglyceride and 0.63g sucrose ester, then add 28.85g Functional grease, fully stirred and dissolved at 70°C to 500mL; high-speed shearing at 10,000 rpm for 5 minutes; use a high-pressure homogenizer to homogenize the above emulsion, the condition is 30MPa, homogenize 3 times; finally The inlet temperature of spray drying is 170-180°C, the outlet temperature is 85-95°C, and the feed rate is 5-10mL / min.

[0038] Regarding the different proportions of functional oils, the experiments that help improve diabetes are as follows:

[0039] Select healthy mice with the s...

Embodiment 2

[0047] Preparation of the core material: First, take 20g of chia seed oil and put it into a container, then add 5g of olive oil, and finally add 70g of peanut oil, and stir thoroughly for 10 minutes; make liquid oil, pack it into a jar, and store it at an appropriate temperature.

[0048] Preparation process of functional oil microcapsules containing chia seed gum: Weigh 10g sodium caseinate, 10g chia seed gum, 48.5g high amylose corn starch, 1.05g monoglyceride and 0.45g sucrose ester, then add 30g functional oil , fully stirred and dissolved at 70°C to 500mL; high-speed shearing at 10,000 rpm for 5 minutes; use a high-pressure homogenizer to homogenize the above emulsion, the condition is 30MPa, homogenize 3 times; finally spray dry The inlet temperature is 170-180°C, the outlet temperature is 85-95°C, and the feed rate is 5-10mL / min.

Embodiment 3

[0050] The preparation process of the core material: first add 30g of chia seed oil into the container, then add 20g of olive oil, and finally add 50g of peanut oil, mix thoroughly; make liquid oil, pack and store at an appropriate temperature.

[0051]Preparation process of functional oil microcapsules containing chia seed gum: Weigh 10g sodium caseinate, 30g chia seed gum, 18.5g high amylose corn starch, 0.75g monoglyceride and 0.75g sucrose ester, then add 40g functional oil , fully stirred and dissolved at 70°C to 500mL; high-speed shearing at 10,000 rpm for 5 minutes; use a high-pressure homogenizer to homogenize the above emulsion, the condition is 30MPa, homogenize 3 times; finally spray dry The inlet temperature is 170-180°C, the outlet temperature is 85-95°C, and the feed rate is 5-10mL / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com