Preparation method and application of hydrogel of three-layer net structure

A network structure, hydrogel technology, applied in the field of materials, can solve the problems of low sensitivity coefficient, many preparation raw materials, small strain stretching range, etc., to enhance toughness and tensile strength, improve toughness and mechanical properties, good linear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

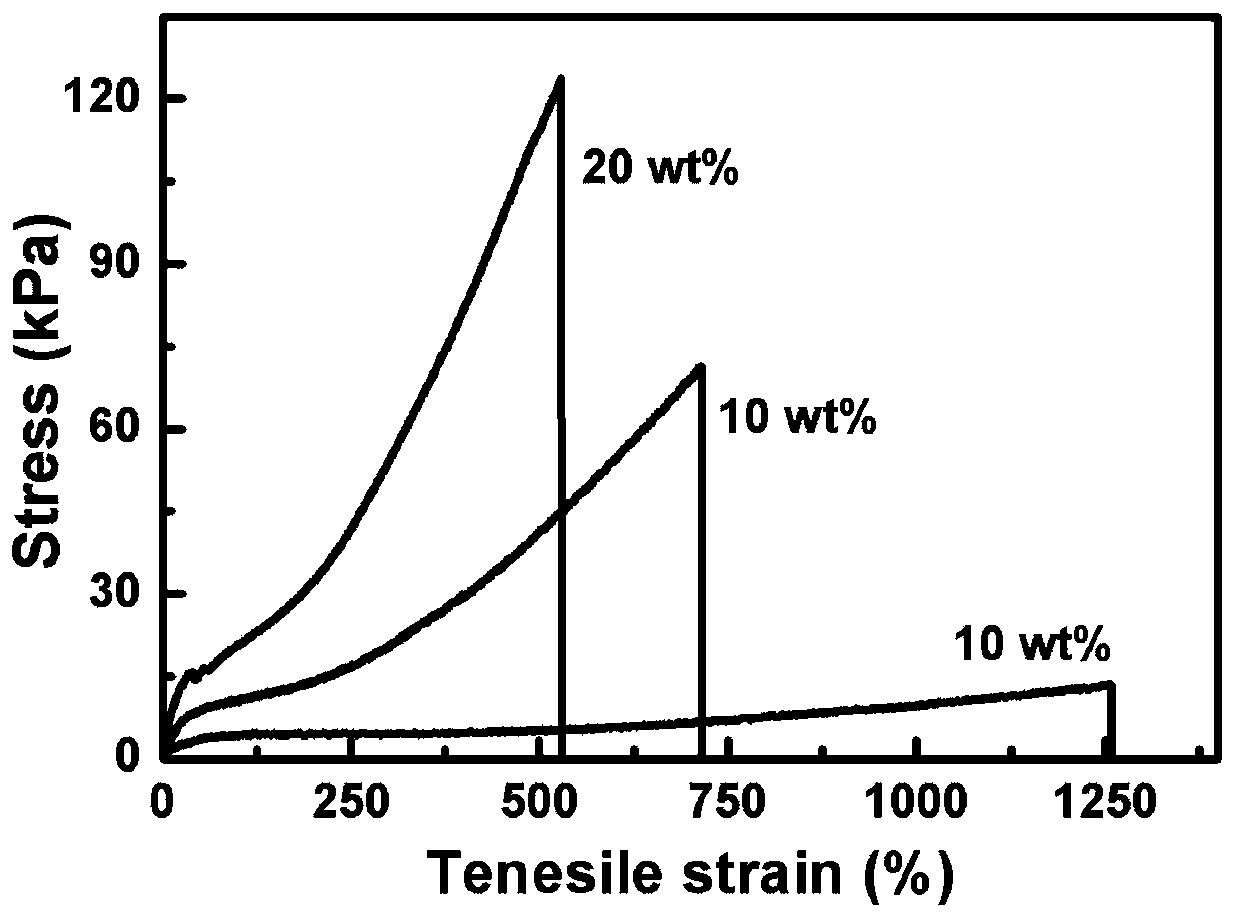

[0038] Step 1: Mix 10 grams of polyvinyl alcohol (molecular weight: 95,000, degree of hydrolysis: 95%) with 90 grams of deionized water, then heat and stir at 90°C for 3 hours, until the PVA is completely dissolved to form a transparent mass concentration of 10wt % PVA aqueous solution;

[0039] Step 2: Dissolving 0.9 gram of borax in 99.1 mL of deionized water, stirring for 5 minutes to completely dissolve it, and preparing a borax aqueous solution with a concentration of 0.9 wt %;

[0040] Step 3: Put the PVA aqueous solution obtained in step 1 into a beaker, add an equal volume of borax aqueous solution, and stir slowly with a glass rod for 1 hour to fully cross-link the PVA aqueous solution and borax aqueous solution to form a pre-hydrogel;

[0041] Step 4: Take out an appropriate amount of pre-hydrogel and place it in a polytetrafluoroethylene mold (40×40×2mm 3 ), cover the glass plate and apply a weight of 3 kg to press for 3 hours to make it shape;

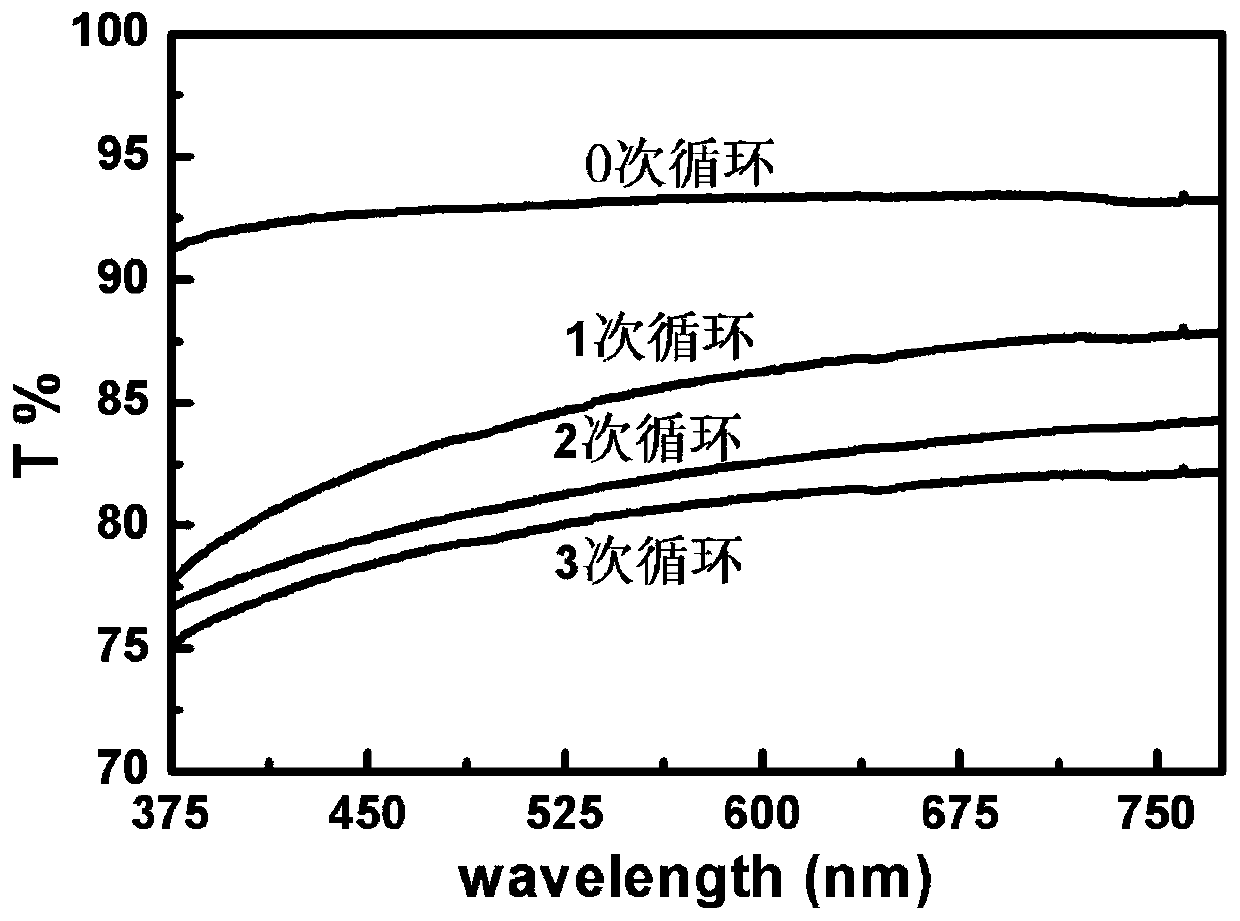

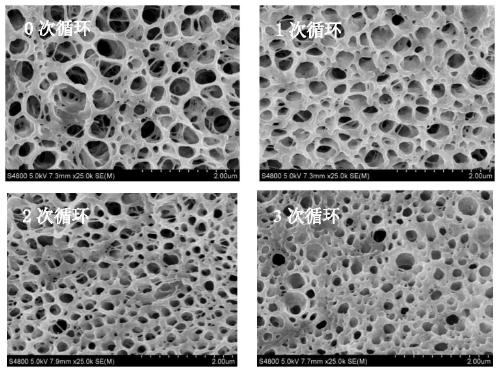

[0042] Step 5: Fi...

Embodiment 2

[0044] Change the concentration of the PVA aqueous solution in Step 1 of Implementation 1 to 15 wt%, and keep the rest of the steps unchanged.

Embodiment 3

[0046] Change the concentration of the PVA aqueous solution in Step 1 of Implementation 1 to 20 wt%, and the remaining steps remain unchanged.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com