Polyester tackifying/nucleating special auxiliary agent, preparation thereof and application thereof in PET modification

A technology of polyester and nucleation, which is applied in the field of polyester viscosifying/nucleating special additives and its preparation and application in PET modification, which can solve the problems of long injection molding cycle, low crystallization rate, and few injection molding, etc. problems, to achieve low cost, improve molding performance, improve mechanical properties and heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

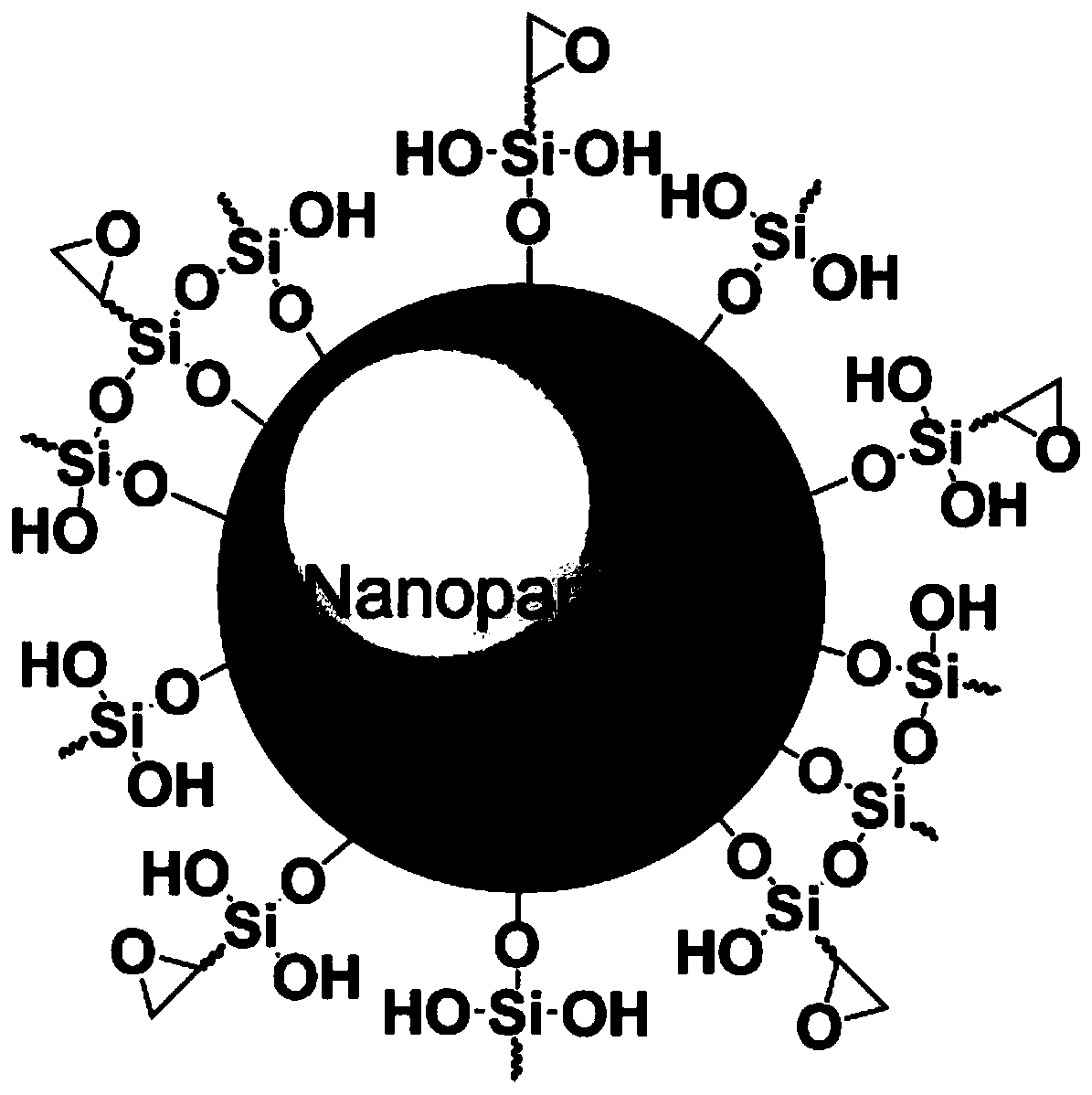

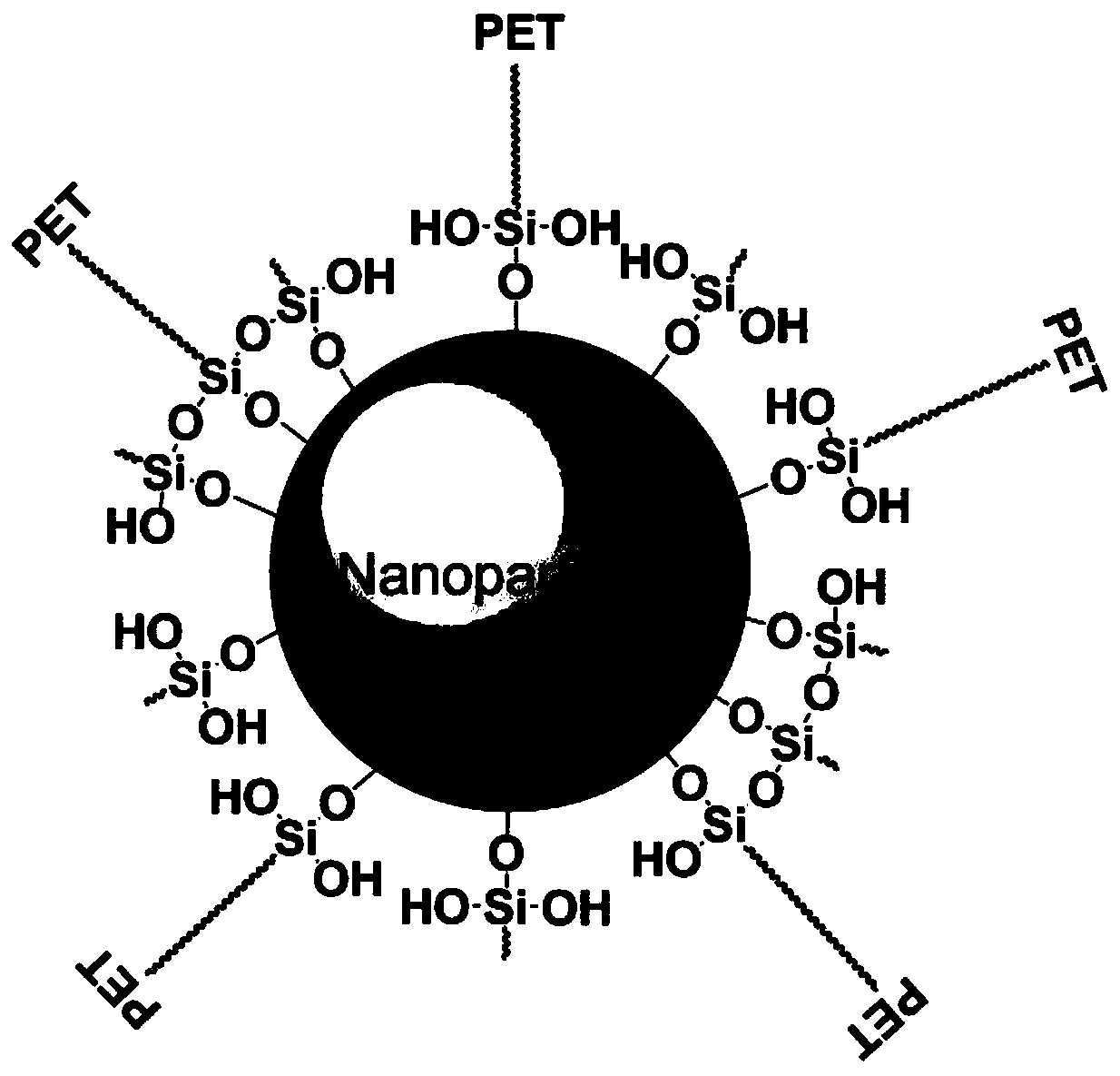

[0040] 240mL deionized water, 60mL industrial alcohol, 30g SiO 2 (Wanjing New Materials Co., Ltd., VK-SP30), 0.261g γ-(2,3-epoxypropoxy)propyltrimethoxysilane (KH-560) (Aladdin Shanghai Biochemical Co., Ltd.), 0.710g Octyltriethoxysilane (KH-832) (Aladdin Shanghai Biochemical Co., Ltd.) (the mol ratio of the two siloxanes is 3:7), mix well under mechanical stirring, then adjust the pH with 10wt% dilute hydrochloric acid When the value reaches 4, stir at room temperature for 6 h to obtain a nanoslurry with a solid content of 10 wt%. The obtained nano-slurry is centrifuged (10000rpm, desktop high-speed centrifuge, H / T16MM, Hunan Hexi Instrument Equipment Co., Ltd.), and the precipitate obtained by centrifugation is dried at 80°C for 12h in a blast oven to obtain modified nano-SiO 2 particles.

[0041] The obtained modified nano-SiO 2The granules are added to PET (Wahaha pure water bottle material), the added amount is 1wt% of the PET amount, mixed evenly, added to the torque ...

Embodiment 2

[0047] Other is the same as embodiment 1, but will modify nano-SiO 2 The amount of particles added to PET was changed to 2wt% to obtain modified PET, and the effect of thickening and inducing crystallization was measured. The results show that the intrinsic viscosity number of PET increases from 0.45 to 0.96, and the viscosity increasing effect is obvious. The crystallinity increased from 34.7% to 37.7%.

Embodiment 3

[0055] Others are the same as in Example 1, but the method for preparing the nano-slurry is changed to: Pour the slurry adjusted with dilute hydrochloric acid into a planetary ball mill (Nanjing University Instrument Factory, QM-3SP2) for ball milling, and the ball milling condition is: zirconium beads with a diameter of 0.5 mm, mass 350g, rotational speed 350rpm, ball milling time 5h, to obtain nano-slurry, after spray drying (190°C, slurry inlet rate 5mL / min), modified nano-SiO 2 Granules, after melting and mixing with PET, measured PET viscosity and induced crystallization effects. The results show that the intrinsic viscosity number of PET increases from 0.45 to 0.98, and the viscosity-increasing effect is obvious. The crystallinity increased from 34.7% to 37.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com