A kind of mofs fluorescent probe for detecting tetrabromobisphenol A, preparation method and application

A technology of tetrabromobisphenol and fluorescent probe, which is applied in the direction of fluorescence/phosphorescence, chemical instruments and methods, luminescent materials, etc., can solve the problems of restricting wide application, high cost, complex instruments and equipment, etc., and achieve good application prospects, The effect of low cost and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] A method for preparing a MOFs fluorescent probe for detecting tetrabromobisphenol A, comprising the following steps:

[0041] Preparation of S1 and MOF-74(Zn)

[0042] Dissolve 2,5-dihydroxyterephthalic acid and divalent zinc salt or divalent zinc salt hydrate separately in DMF solution, then slowly add 2,5-dihydroxyterephthalic acid solution to divalent zinc salt Or in the solution of divalent zinc salt hydrate, stir at room temperature to obtain yellow solid MOF-74(Zn), wash clean;

[0043] Preparation of S2 and MOF-74(Zn)-en

[0044]The cleaned MOF-74(Zn) was added to the solution of ethylenediamine (en), stirred at room temperature, filtered, washed and dried at room temperature to obtain the fluorescent probe MOF-74(Zn)-en.

[0045] Preferably, the molar ratio of 2,5-dihydroxyterephthalic acid and divalent zinc salt or divalent zinc salt hydrate described in step S1 is (0.8-1.2): (2.5-3.7); preferably 1.2: 3.12;

[0046] In the step S2, each 131 mg of MOF-74 (Z...

Embodiment 1

[0061] The preparation method of MOFs fluorescent probe includes the following steps:

[0062] Preparation of S1 and MOF-74(Zn)

[0063] 2,5-Dihydroxyterephthalic acid (239 mg, 1.20 mmol) and Zn(OAc) 2 ·2H 2 O (686 mg, 3.12 mmol) were respectively dissolved in 20 ml of DMF solution, then 2,5-dihydroxyterephthalic acid solution was slowly added to Zn(OAc) 2 ·2H 2 O solution, stirred at room temperature for 18 h to obtain 269.5 mg of yellow solid MOF-74(Zn), which was cleaned.

[0064] The cleaning method of MOF-74 (Zn) in described step S1 comprises the following steps:

[0065] S11. Wash 100 mg of freshly prepared MOF-74(Zn) with 20 ml of N,N-dimethylformamide (DMF) three times, and then soak in 20 ml of methanol solution to remove the MOFs-74(Zn) The residual ligand 2,5-dihydroxyterephthalic acid and DMF are dried at room temperature at 20-30°C.

[0066] S12. Soak the MOF-74(Zn) obtained in step S11 in 20ml of water at a temperature of 20-30°C for 30min to remove the su...

Embodiment 2

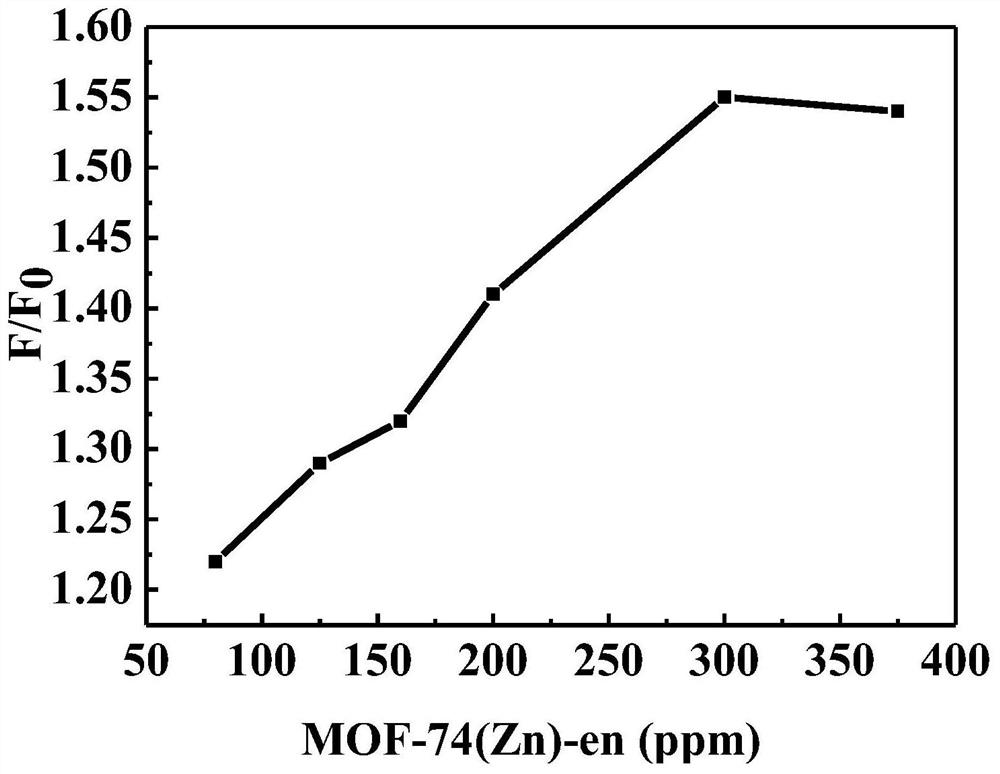

[0071] To explore the effect of MOF-74(Zn)-en concentration, the sensitivity of MOF-74(Zn)-en solution with concentrations of 80, 100, 125, 160, 200, 300, and 375 ppm to TBBPA (150 ppb) was investigated. like image 3 As shown, the photoluminescence enhancement ratio (expressed as F / F0, where F0 and F are the photoluminescence intensities before and after the addition of TBBPA, respectively) increased with the concentration of MOF-74(Zn)-en solution in the range of 80-300 ppm , and then the enhancement factor decreased slightly with the increase of concentration, so the highest selectivity was found in MOF-74(Zn)-en at 300 ppm. Therefore, in the further study, 300ppm MOF-74(Zn)-en solution was finally chosen to measure TBBPA.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com