Preparation method of elytrigia trichophora silage

A technology of Thipyrium tenatum and silage, which is applied to the preservation method of animal feed raw materials, animal feed, animal feed, etc., can solve the problems of roughness of Thinium tenatum grass, difficult plant feed, low feeding value, etc., and achieve Improving immunity, reducing morbidity, good palatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

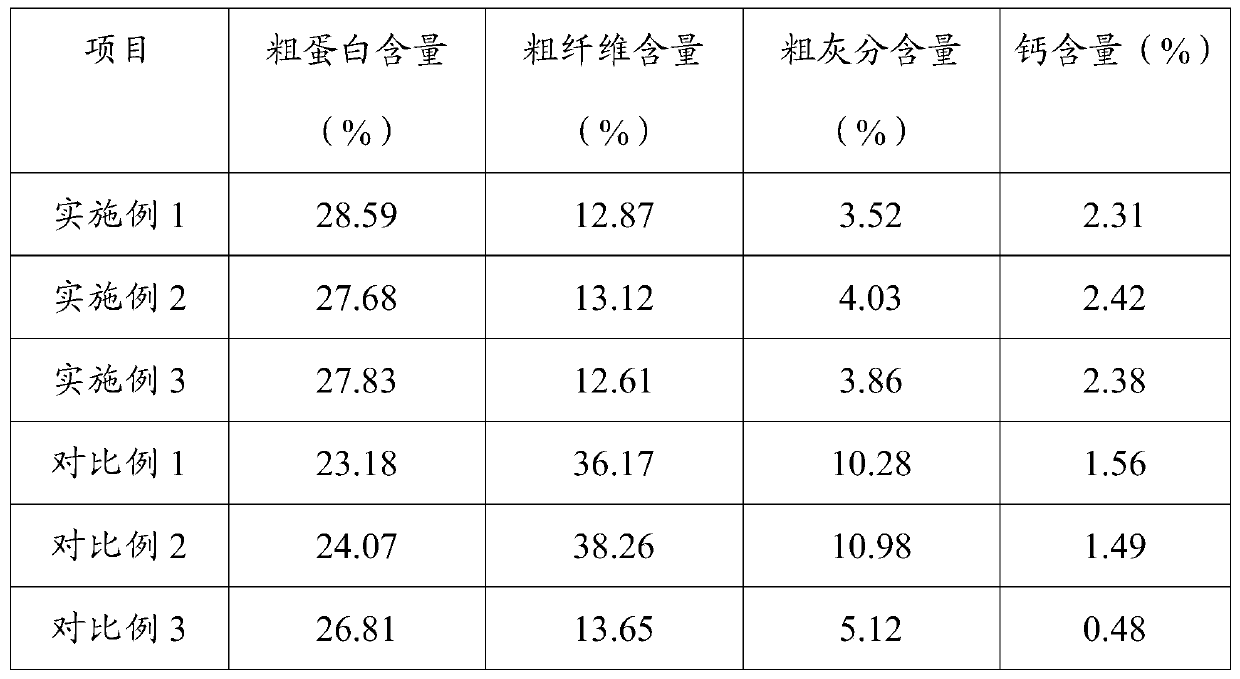

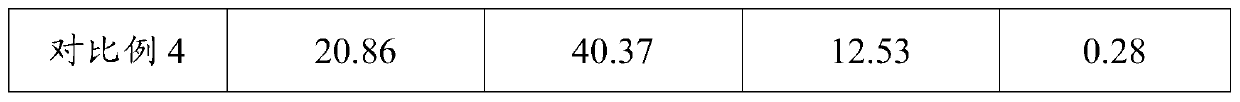

Embodiment 1

[0033] A method for preparing silage of Thinopyrum tomentosa, specifically implemented according to the following steps:

[0034] Step 1: Cut Thinium tomentosa into 1-2cm sections and soak it with a sodium bicarbonate solution with a mass concentration of 5%, take it out and dry it, then soak it with acid solution, take it out after soaking, drain it, and make it dry The water content of the wheatgrass reaches 40%, and the pretreated Thiopyrum tomentosa is obtained;

[0035] Among them, the acid solution is prepared from acetic acid solution with a mass concentration of 5% and sodium lignosulfonate at a mass ratio of 100:3;

[0036] Step 2, adding a compound enzyme equivalent to 0.1% of the weight of the pretreated Thipyrum tomentosa in step 1, enzymatically hydrolyzing at 60° C. for 3 hours to obtain the enzymolyzed material;

[0037] Wherein, the compound enzyme is formed by mixing cellulase and amylase at a mass ratio of 2:1, and the enzyme activities of cellulase and amyl...

Embodiment 2

[0043] A method for preparing silage of Thinopyrum tomentosa, specifically implemented according to the following steps:

[0044] Step 1: Cut Thinium tomentosa into 1-2cm sections and soak it with a sodium bicarbonate solution with a mass concentration of 5%, take it out and dry it, then soak it with acid solution, take it out after soaking, drain it, and make it dry The water content of the wheatgrass reaches 45%, and the pretreated Thiopyrum tomentosa is obtained;

[0045] Among them, the acid solution is prepared from acetic acid solution with a mass concentration of 5% and sodium lignosulfonate in a mass ratio of 100:4;

[0046]Step 2, adding a compound enzyme equivalent to 0.2% of the weight of the pretreated Thipyrum tomentosa in step 1, enzymatically hydrolyzing at 40° C. for 5 hours to obtain the enzymolyzed material;

[0047] Wherein, the compound enzyme is formed by mixing cellulase and amylase at a mass ratio of 2:1, and the enzyme activities of cellulase and amyla...

Embodiment 3

[0053] A method for preparing silage of Thinopyrum tomentosa, specifically implemented according to the following steps:

[0054] Step 1: Cut Thinium tomentosa into 1-2cm sections and soak it with a sodium bicarbonate solution with a mass concentration of 5%, take it out and dry it, then soak it with acid solution, take it out after soaking, drain it, and make it dry The water content of the wheatgrass reaches 50%, and the pretreated Thiopyrum tomentosa is obtained;

[0055] Wherein, the acid solution is prepared from acetic acid solution with a mass concentration of 5% and sodium lignosulfonate at a mass ratio of 100:5;

[0056] Step 2, adding a compound enzyme equivalent to 0.3% of the weight of the pretreated Thipyrum tomentosa in step 1, and performing enzymatic hydrolysis at 50° C. for 4 hours to obtain an enzymatic hydrolyzed material;

[0057] Wherein, the compound enzyme is formed by mixing cellulase and amylase at a mass ratio of 2:1, and the enzyme activities of cel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Enzyme activity | aaaaa | aaaaa |

| Packing density | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com