A self-generating steam protection and fire extinguishing technology

A steam and self-generated technology, which is applied in fire rescue and other fields, can solve the problems of complex equipment, affecting the service life of the furnace body, high cost of foam fire extinguishing and nitrogen fire extinguishing, and achieves the effect of fast water evaporation, simple structure, and rapid cooling and fire extinguishing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

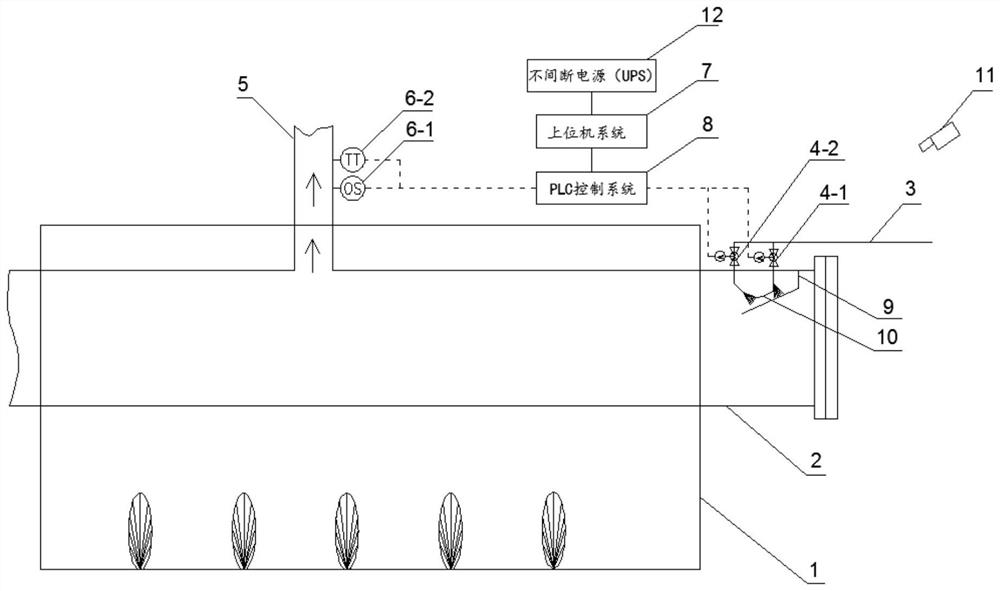

[0027] Embodiment one, such as figure 1 As shown, a self-generating steam protection and fire extinguishing technology includes: after the remote monitoring system detects a fire in the reaction chamber, the operation of the explosion-proof solenoid valve is controlled remotely through the host computer system and the PLC control system, and the water source passes through the fog in the reaction chamber. The atomizing nozzle is sprayed onto the partition in the reaction chamber in the form of water mist, the partition is installed inside the reaction chamber, and is arranged obliquely relative to the horizontal plane, and the spraying direction of the atomizing nozzle is aligned with the partition of the partition On the inclined surface, the water mist instantly evaporates into steam to reduce the problem of combustible gas in the reaction chamber, and at the same time dilute the concentration of combustible gas and oxygen. The amount of spray water can be controlled by detec...

Embodiment 2

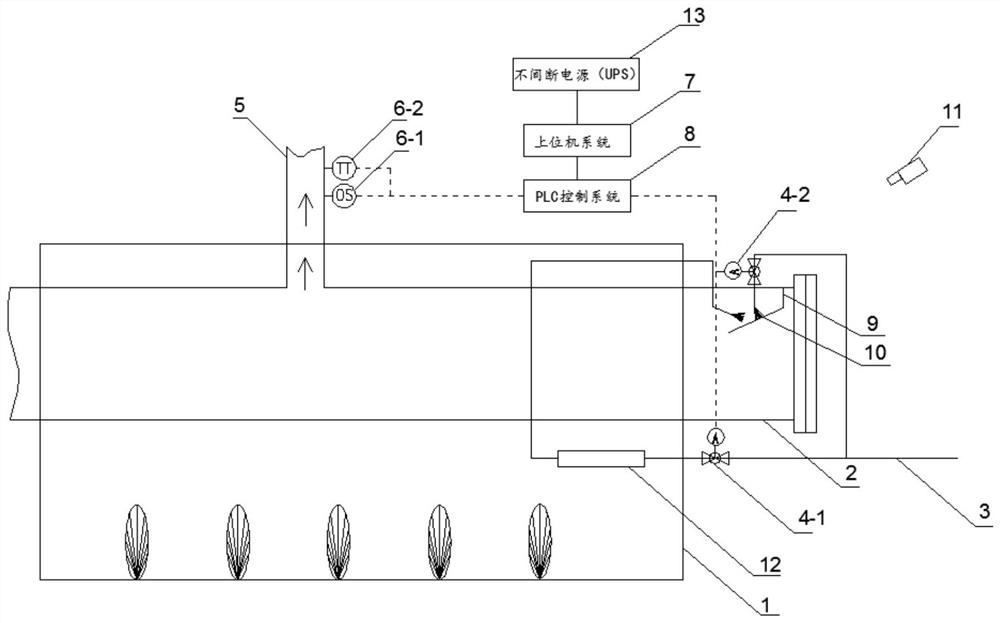

[0033] Embodiment two, such as figure 2 As shown, a self-generating steam protection and fire extinguishing technology includes: after the remote monitoring system detects a fire in the reaction chamber, the operation of the explosion-proof solenoid valve is controlled remotely through the host computer system and the PLC control system, and the water source passes through the fog in the reaction chamber. The atomizing nozzle is sprayed onto the partition in the reaction chamber in the form of water mist, the partition is installed inside the reaction chamber, and is arranged obliquely relative to the horizontal plane, and the spraying direction of the atomizing nozzle is aligned with the partition of the partition On the inclined surface, the water mist instantly evaporates into steam to reduce the problem of combustible gas in the reaction chamber, and at the same time dilute the concentration of combustible gas and oxygen. The amount of spray water can be controlled by dete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com