TiO2 hollow spheres and preparation method thereof

A technology of hollow balls and core-shell balls is applied in the field of TiO2 hollow balls and their preparation, which can solve the problems of low utilization rate of solar energy and the like, and achieve the effect of simple and easy method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A kind of TiO 2 The preparation method of hollow sphere comprises the following steps:

[0032] 1) Mix ethylene glycol and acetone at a mass ratio of 2:1 to obtain solution A;

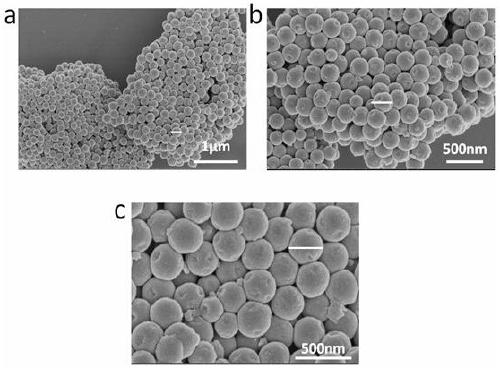

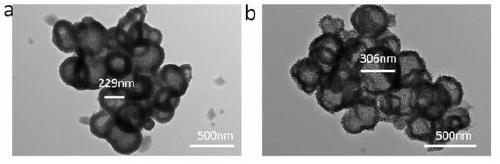

[0033] 2) Add mesoporous carbon spheres with a particle size of 229nm into solution A, and ultrasonically disperse them uniformly to obtain suspension B;

[0034] 3) Add tetrabutyl titanate to suspension B, the mass ratio of tetrabutyl titanate to mesoporous carbon spheres is 5:1, and obtain suspension C after ultrasonic dispersion;

[0035] 4) Transfer the suspension C to a magnetically stirred high-pressure reactor with a filling degree of 50% and a magnetic stirring speed of 300r / min, and react at 150°C for 12 hours to obtain the solvothermal product D;

[0036] 5) The solvothermal product D was centrifuged, washed with deionized water and ethanol, dried at 80°C for 12 hours, and ground to obtain mesoporous carbon @TiO 2 Nucleus shell ball.

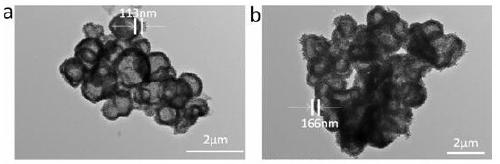

[0037] 6) Integrating mesoporous carbon @TiO ...

Embodiment 2

[0039] A kind of TiO 2 The preparation method of hollow sphere comprises the following steps:

[0040] 1) Mix ethylene glycol and acetone at a mass ratio of 2:1 to obtain solution A;

[0041] 2) Add mesoporous carbon spheres with a particle size of 229nm into solution A, and ultrasonically disperse them uniformly to obtain suspension B;

[0042] 3) Add tetrabutyl titanate to suspension B, the mass ratio of tetrabutyl titanate to mesoporous carbon spheres is 5:1, and obtain suspension C after ultrasonic dispersion;

[0043] 4) Transfer the suspension C to a magnetically stirred high-pressure reactor with a filling degree of 50% and a magnetic stirring speed of 350r / min, and react at 160°C for 14 hours to obtain the solvothermal product D;

[0044] 5) The solvothermal product D was centrifuged, washed with deionized water and ethanol, dried at 80°C for 12 hours, and ground to obtain mesoporous carbon @TiO 2 Nucleus shell ball.

[0045] 6) Integrating mesoporous carbon @TiO ...

Embodiment 3

[0047] A kind of TiO 2 The preparation method of hollow sphere comprises the following steps:

[0048] 1) Mix ethylene glycol and acetone at a mass ratio of 3:1 to obtain solution A;

[0049] 2) Add mesoporous carbon spheres with a particle size of 306nm into solution A, and ultrasonically disperse them uniformly to obtain suspension B;

[0050] 3) Add tetrabutyl titanate to suspension B, the mass ratio of tetrabutyl titanate to mesoporous carbon spheres is 5:1, and obtain suspension C after ultrasonic dispersion;

[0051]4) Transfer the suspension C to a magnetically stirred high-pressure reactor with a filling degree of 80% and a magnetic stirring speed of 400r / min, and react at 180°C for 18 hours to obtain the solvothermal product D;

[0052] 5) The solvothermal product D was centrifuged, washed with deionized water and ethanol, dried at 90°C for 20 hours, and ground to obtain mesoporous carbon @TiO 2 Nucleus shell ball.

[0053] 6) Integrating mesoporous carbon @TiO 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com