Disc type labyrinth valve caged structure brazing method

A brazing method and butterfly technology, applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problem of poor brazing performance between solder and butterfly base material, inability to strictly seal the butterfly, and curved surface of the butterfly, etc. problem, to achieve the effect of increasing the types of brazing, reducing deformation and reducing thermal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will now be described in further detail with reference to the drawings.

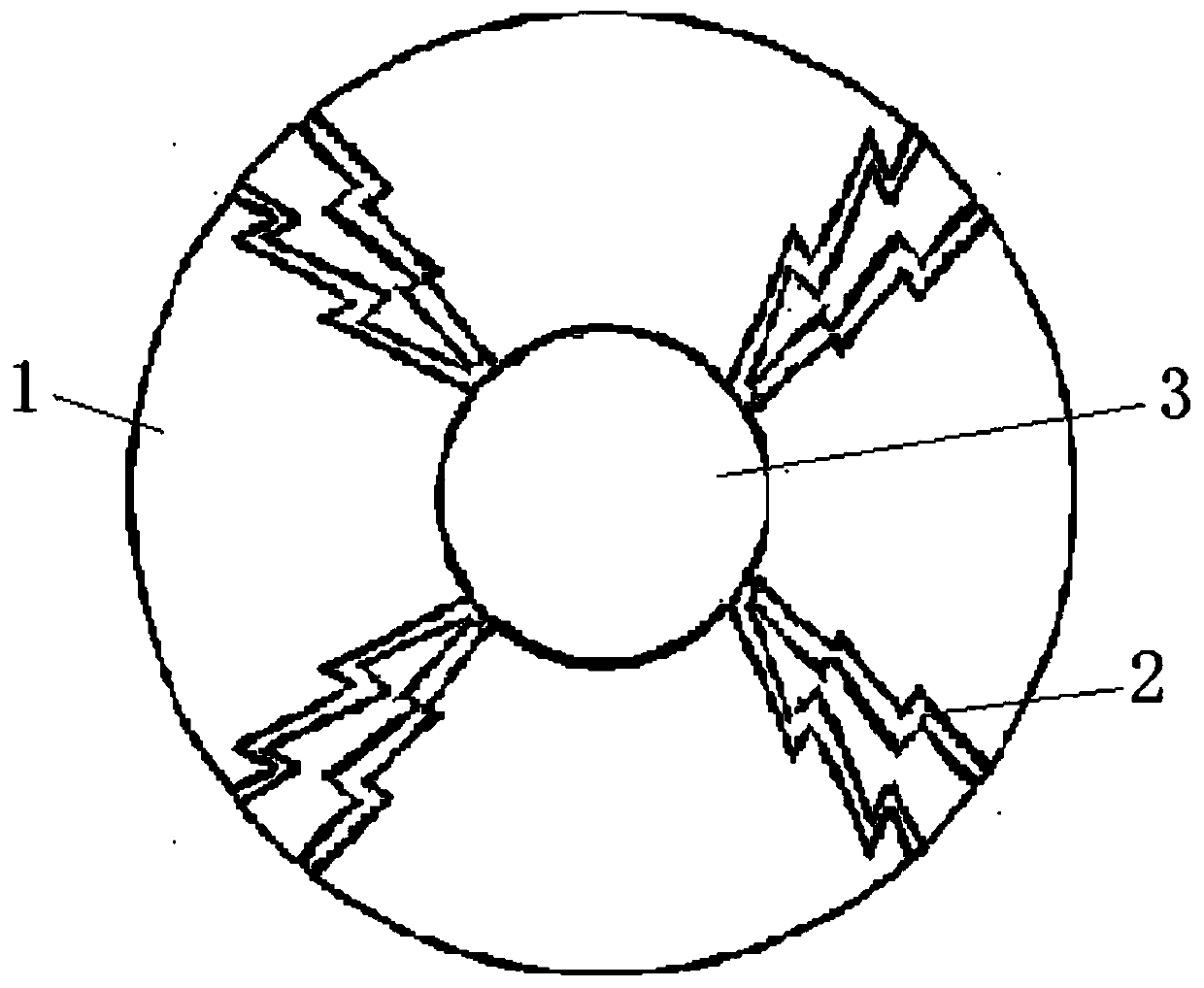

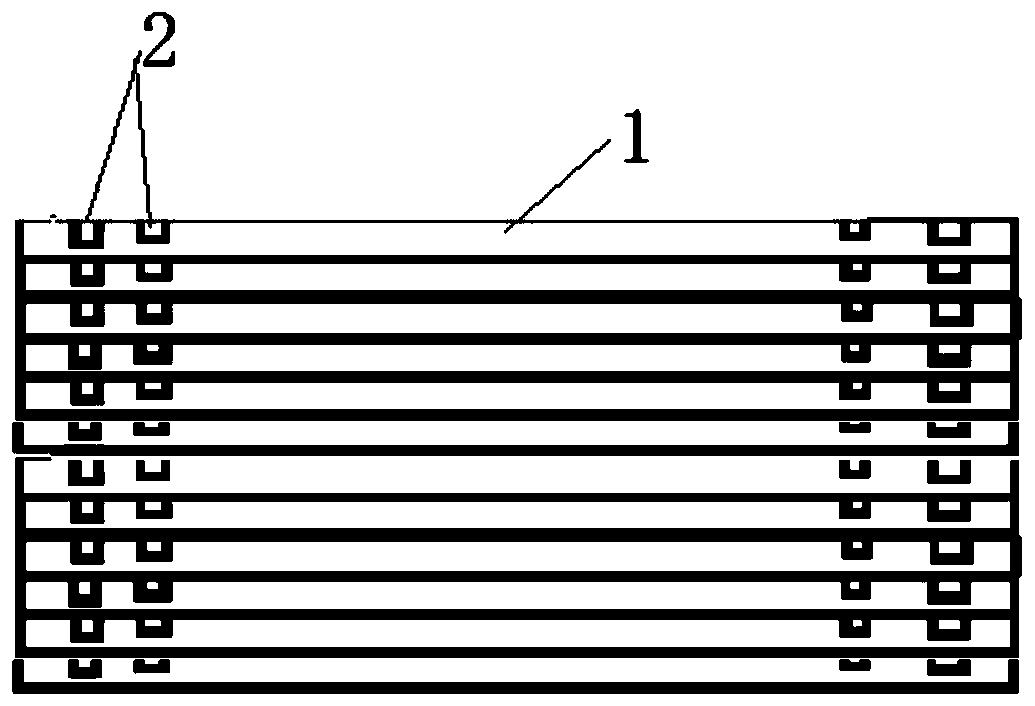

[0019] Firstly, the disc substrate 1 (the disc base material is generally 316 stainless steel, or other alloy steel, 316 stainless steel is used in this embodiment), which helps increase the welding surface area. Next, electroless nickel plating is performed on the surface of the butterfly substrate 1 with a thickness of 10 microns. For electroless nickel plating, choose low-phosphorus nickel plating as much as possible. On the one hand, the surface hardness will be reduced, and secondly, the purity of the nickel surface will be high, which helps the solder's wettability. Electroless nickel plating can improve the wettability of the butterfly substrate 1 and the solder, which can make the brazing area intact and increase the adhesion. Moreover, a variety of solders, mainly silver and copper solders, are modified with nickel on the surface It has a better brazing effect. At the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com