Multi-shaft synchronous operator and control system thereof

A multi-axis synchronization and operating system technology, applied in the direction of program-controlled manipulators, manufacturing tools, manipulators, etc., can solve problems such as poor reliability, low efficiency, and high technical difficulty, so as to improve operating speed, ensure real-time performance, and simplify calculations volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

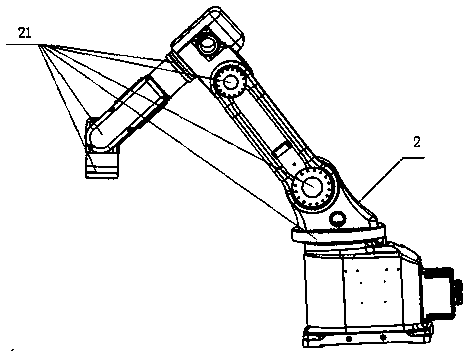

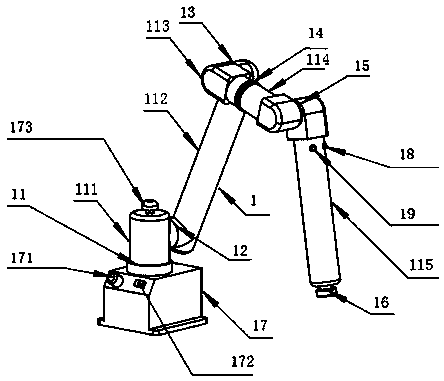

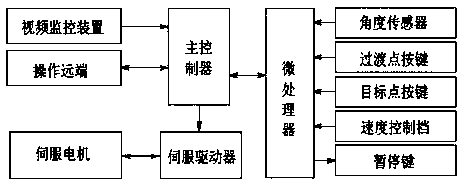

[0045] The six-axis robot 2 is controlled by servo motors at the positions of the six designed joints 21 , that is, it includes six-way servo motors; and six-way servo drives are connected to the six-way servo motors. The output terminals of the main controller of the robot control system are respectively connected with six servo drives. Each servo motor is equipped with an encoder to feed back the rotation angle (position) of the servo motor. The encoded signal is sent to the servo driver to form a real-time closed loop. At the same time, the encoded signal is sent to the main controller, and then the main controller presses a certain The needs are processed, and then the control signal is sent to the servo driver to control the state or position of the servo motor, forming a double closed loop to achieve precise control of the position and speed of the servo motor rotation. The six-axis synchronous manipulator is equipped with six independent angle sensors to detect the six-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com