A kind of organic porous polymer and its preparation and application

A porous polymer, organic technology, applied in the field of porous structure polymer organic electroluminescent materials, can solve the problems of wasting time, low efficiency, increasing experimental cost, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

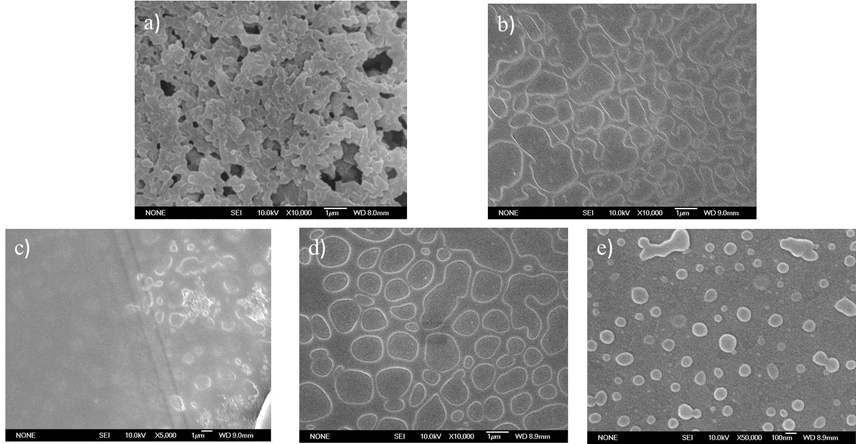

[0051] Example 1: Synthesis of an organic porous polymer whose building monomer 1,3,6,8-tetra-substituted pyrene accounts for 1% of the total molar amount of the polymer.

[0052] 1), the synthesis of 1,3,6,8-tetrabromopyrene.

[0053]

[0054] In a 250ml three-necked flask, add 3.26g (10mmol) of pyrene, vacuumize through N 2 3 times each to fully exhaust the air in the flask. 50 ml of THF was added, stirred and mixed at room temperature for 30 min, and 0.6 g (25 mmol) of NaH was added to the flask in 5 times, with an interval of 15 min between each addition. Vacuum again and pass N 2 , dissolve 1.70g (4mmol) of pentatetrabromide in 20ml of THF, slowly drop it into a three-necked flask through an atmospheric separatory funnel within 30min, heat it to 50°C for 6h, then heat it up to 75°C to continue the reaction for 24h.

[0055] After the reaction, the mixed solution was rotary evaporated to remove THF, water was added, and CH 2 Cl 2 Extract 3 times, collect CH 2 Cl ...

Embodiment 2

[0063] Example 2: Synthesis of an organic porous polymer in which the building monomer 1,3,6,8-tetra-substituted pyrene accounts for 5% of the total molar amount of the polymer.

[0064] Weigh M1 0.23g (0.42mmol), M2 0.34g (0.53mmol), M3 0.0259g (0.05mmol), mix them into a 250ml three-necked flask, and pass N 2 3 times each to exhaust the air in the flask. Add 30 ml of toluene (water removed in advance) into the three-necked flask, and stir for 10 min. Weigh 5.0g K 2 CO 3 Dissolve in 15ml water, measure 1ml Aliquant 336 phase transfer catalyst and dissolve it in 5ml anhydrous toluene, respectively in N 2 Add to the three-necked flask under the protection, vacuumize through N 2 1 time each. 0.05 g of tetrakis(triphenylphosphine) palladium catalyst was weighed into a three-necked flask, heated to 100° C., and the reaction was stopped after refluxing for 3 days.

[0065] The reaction solution was cooled to room temperature, water was added, extracted with toluene, the extra...

Embodiment 3

[0067] Example 3: Synthesis of an organic porous polymer in which the building monomer 1,3,6,8-tetra-substituted pyrene accounts for 10% of the total molar amount of the polymer.

[0068] Weigh M1 0.19g (0.35mmol), M2 0.35g (0.55mmol), M3 0.0518g (0.1mmol), mix them into a 250ml three-necked flask, and pass N 2 3 times each to exhaust the air in the flask. Add 30 ml of toluene (water removed in advance) into the three-necked flask, and stir for 10 min. Weigh 5.0g K 2 CO 3 Dissolve in 15ml water, measure 1ml Aliquant 336 phase transfer catalyst and dissolve it in 5ml anhydrous toluene, respectively in N 2 Add to the three-necked flask under the protection, vacuumize through N 2 1 time each. 0.05 g of tetrakis(triphenylphosphine) palladium catalyst was weighed into a three-necked flask, heated to 100° C., and the reaction was stopped after refluxing for 3 days.

[0069] The reaction solution was cooled to room temperature, water was added, extracted with toluene, the extra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

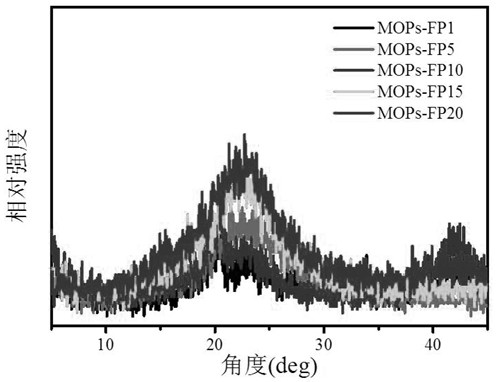

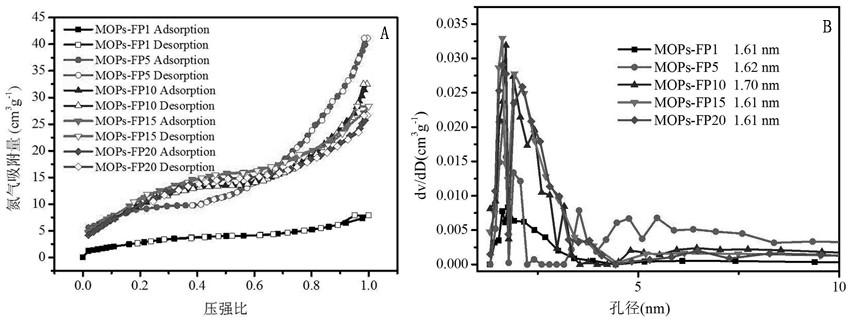

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com