Antibacterial TPV (thermoplastic vulcanizate) material for nurse shoes

A technology for shoes and nurses, which is applied in the field of shoe materials, can solve the problems of poor ozone resistance, poor polyurethane slip resistance, and high cost, and achieve excellent dry and wet skid resistance, good elasticity and stretchability, and good processability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0129] The preparation method of the modified calcium carbonate of the present invention is: adding deionized water to a certain amount of calcium carbonate to disperse for 30 minutes (ultrasonic assistance can be used to improve the dispersion effect), then heating the system temperature to 60-70°C, adding surface The active agent is stirred and reacted for 2-3 hours, cooled to room temperature, filtered, the filter cake is washed with water, dried and ground to obtain the product.

[0130] Surfactant refers to a substance that can significantly change the interface state of its solution system by adding a small amount. With fixed hydrophilic and lipophilic groups, they can be oriented on the surface of the solution. The molecular structure of the surfactant is amphiphilic: one end is a hydrophilic group, and the other end is a hydrophobic group.

[0131] Still further preferably, the surfactant of the present invention is a silicone surfactant.

[0132] In a preferred embod...

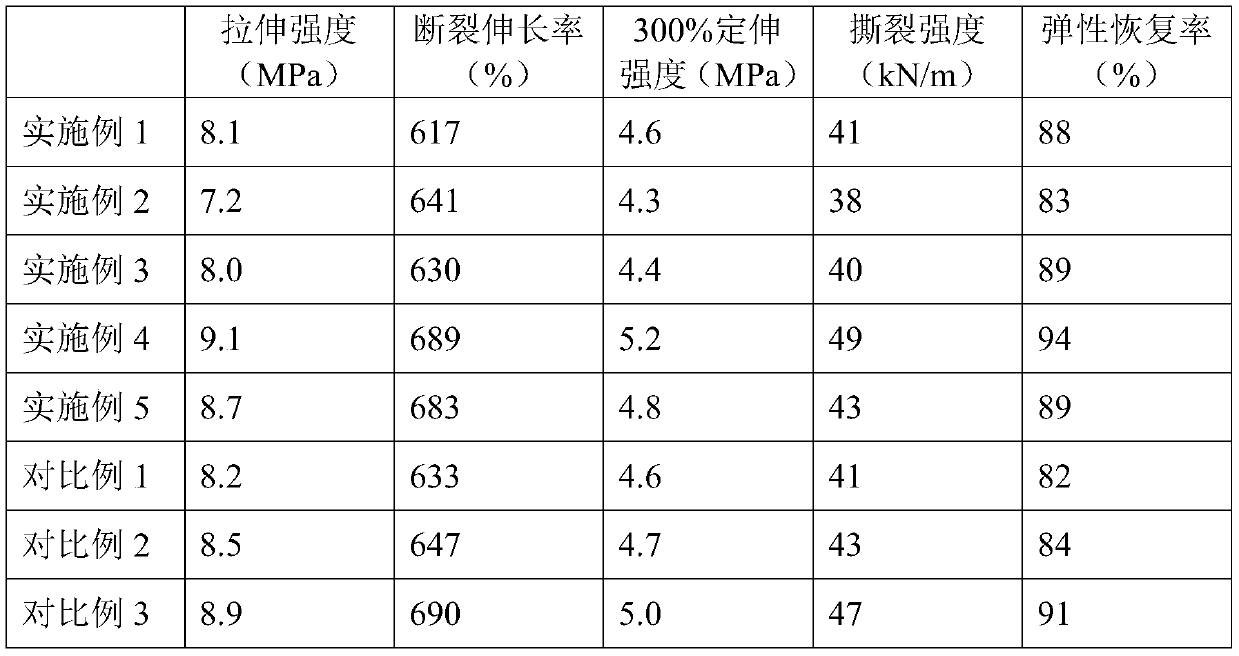

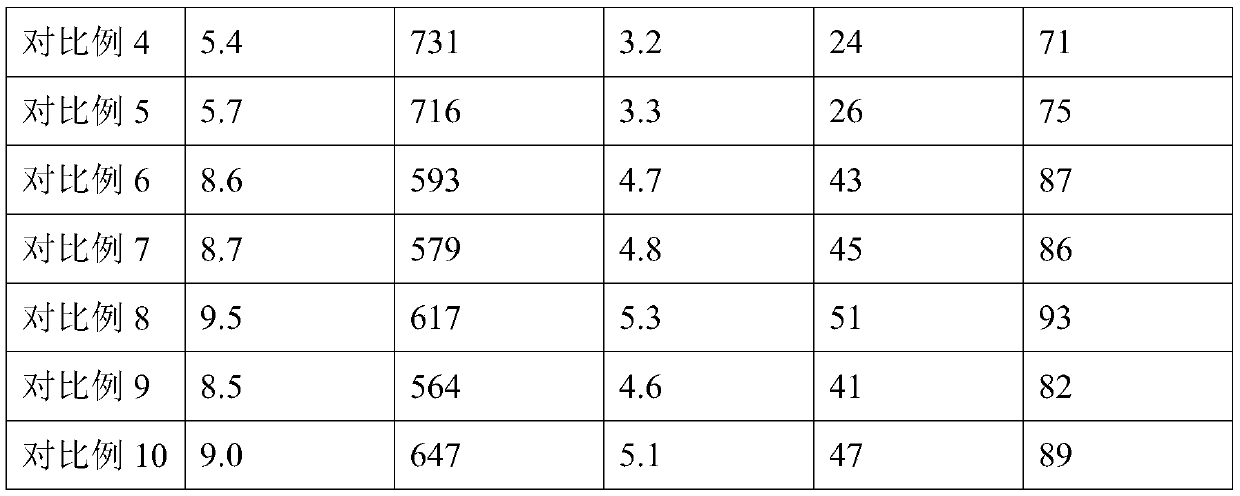

Embodiment 1

[0155] Embodiment 1 of the present invention provides a kind of TPV material for antibacterial nurse shoes, the raw material of described antibacterial nurse shoes TPV material comprises, by weight, 10 parts of EPDM rubber, 3 parts of butadiene rubber, 3 parts of butadiene rubber, Part polypropylene, 0.3 part grafted polypropylene, 6 parts hydrogenated styrene-butadiene block copolymer, 15 parts softener, 0.3 part vulcanizing agent, 0.3 part vulcanization accelerator, 0.1 part antioxidant, 10 parts filler ;

[0156] The filler is barium sulfate and calcium carbonate with a mass ratio of 1:1.

[0157] The EPDM rubber is purchased from Exxon in the United States, and the brand name is EPDM8800, wherein the third monomer is ethylidene norbornene, which accounts for 10 wt% of the EPDM rubber, and propylene accounts for 10% by weight of the EPDM rubber. 36.5 wt%.

[0158] The butadiene rubber was purchased from Changzhou Heshan Rubber Co., Ltd.

[0159]The polypropylene is purch...

Embodiment 2

[0175] Embodiment 2 of the present invention provides a kind of TPV material for antibacterial nurse shoes, the raw material of described antibacterial nurse shoes TPV material comprises, by weight, 10 parts of EPDM rubber, 1 part of butadiene rubber, 1 part of butadiene rubber, Part polypropylene, 0.1 part grafted polypropylene, 4 parts hydrogenated styrene-butadiene block copolymer, 10 parts softener, 0.1 part vulcanizing agent, 0.1 part vulcanization accelerator, 0.01 part antioxidant, 5 parts filler , 0.1 part of fungicide;

[0176] The filler is barium sulfate and calcium carbonate with a mass ratio of 1:3.

[0177] The EPDM rubber is purchased from DuPont-Dow in the United States, and the brand name is EPDM4640, wherein the third monomer is ethylidene norbornene, which accounts for 5wt% of the EPDM rubber, and propylene accounts for 5 wt% of the EPDM rubber. 40wt%.

[0178] The butadiene rubber was purchased from Changzhou Heshan Rubber Co., Ltd.

[0179] The polyprop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com