A kind of manufacturing method of annealing drawn steel bar for finishing

A steel bar and annealing technology, which is applied in the field of steel bar and its annealing and drawing process, can solve the problems of increased tool wear and sticking, and achieve good precision machining performance, low cost, stable and uniform metallographic structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The material is 42CrMo steel. The chemical composition of the steel meets the smelting specifications of the industry standard. It belongs to the hypoeutectoid low-alloy steel. The chemical composition is not the design point of this application. Misunderstanding, the chemical composition is not disclosed in this embodiment, and those skilled in the art can refer to the industry standard for this steel grade:

[0030] 1) Steelmaking: Electric furnace + LF furnace + VD vacuum degassing + continuous casting are used to make steel. During the steelmaking process, the S content in the molten steel is adjusted, and the final content is stable at 0.030%. Higher S can make the steel bar In the subsequent rolling process, long strip-shaped sulfide inclusions are formed, which reduces toughness and improves chip breaking performance during machining.

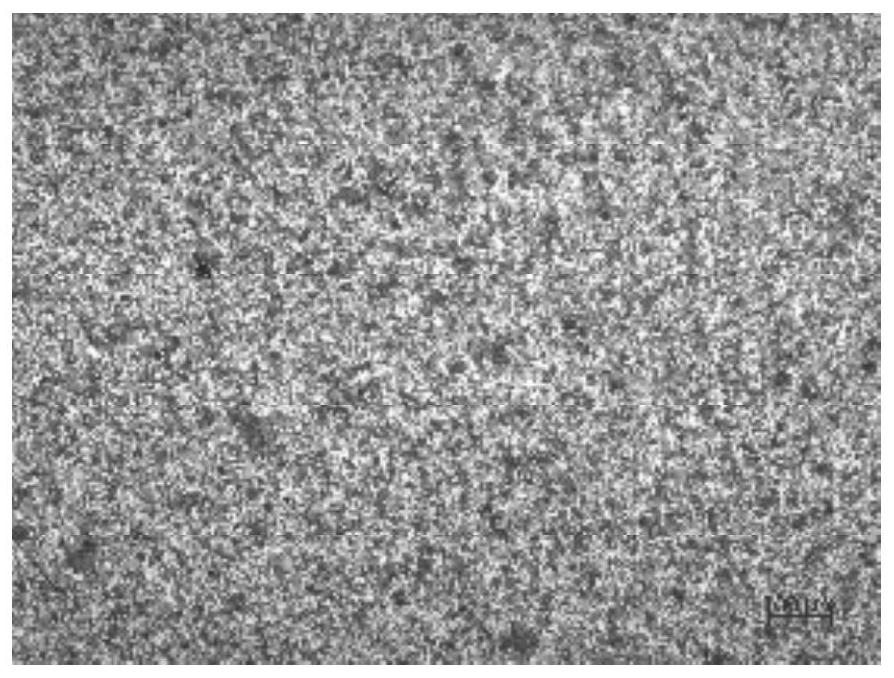

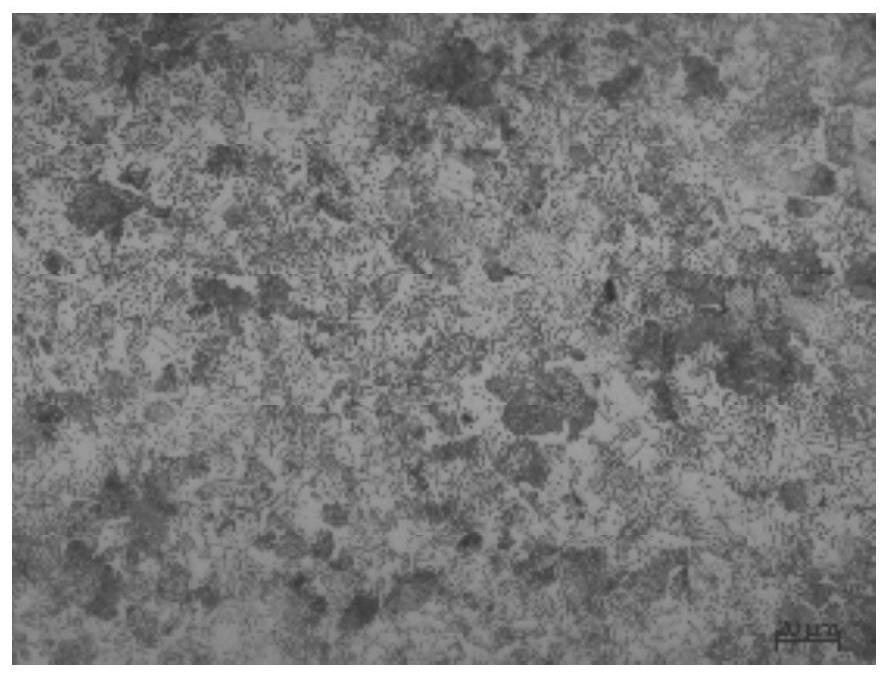

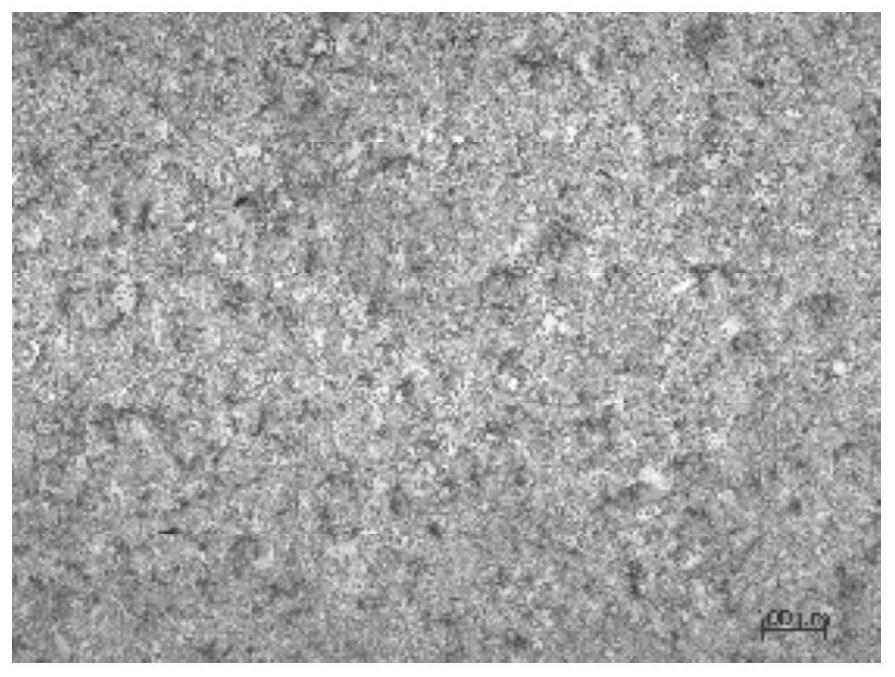

[0031] 2) Rolling: The continuous casting billet is rolled into a 35mm-sized bar, and it is rolled off the line through a long c...

Embodiment 2

[0036] The material is 40Cr steel. The chemical composition of the steel meets the GB standard for the steel grade. It belongs to hypoeutectoid low alloy steel. The specific production steps are:

[0037] 1) Steelmaking: adopt electric furnace / converter + LF furnace + continuous casting to make steel, add sulfur to 0.035% in the molten steel, so that the steel bar will form long strips of sulfide inclusions in the subsequent rolling process, reduce toughness, and improve mechanical properties. Chip breaking performance during machining.

[0038] 2) Rolling: The continuous casting billet is rolled into a 24mma bar, and it is air-cooled to obtain a faster cooling rate (3°C / s) when it is off-line. The cooling rate passes through the bainite region of the CCT curve and ensures that The off-line temperature is lower than 550°C, and a metallographic structure dominated by bainite is obtained. At the same time, there is a small amount of ferrite in the structure. The volume fraction of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com