Preparation method of spunlace fabric

A spunlace cloth and spunlace technology, applied in the field of papermaking, can solve the problems of heavy pollution and high production costs, and achieve the effects of reducing production costs, improving environmental protection, and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

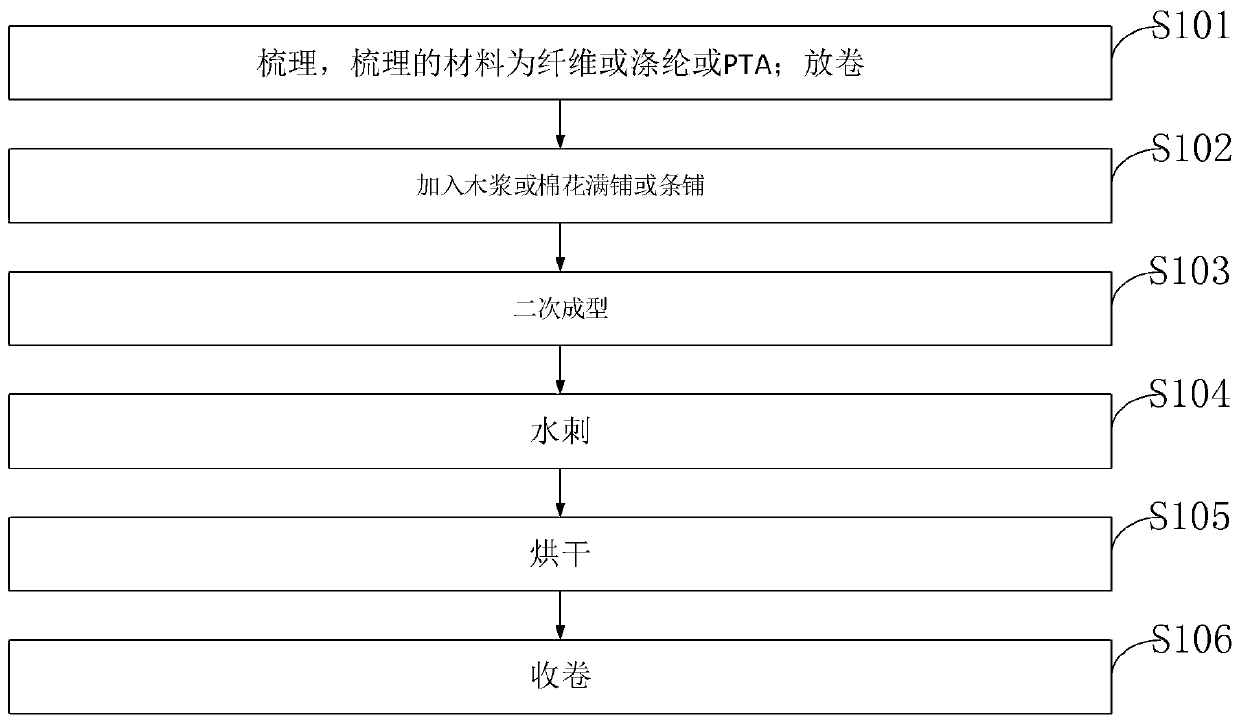

[0057] like figure 1 , the preparation method of the spunlaced cloth provided by the embodiment of the present invention, comprising:

[0058] S101: carding, the material for carding is fiber or polyester or PTA; unwinding.

[0059] S102: add 8g-100g of wood pulp or cotton to spread or strip.

[0060] S103: secondary molding.

[0061] S104: Spunlace.

[0062] S105: drying.

[0063] S106: rewinding.

[0064] In step S103, after being processed by a coarse pulverizer, it is processed by a fine pulverizer, and the fluff pulp or cotton is quantified by a fiber collector, and then transported to the first forming area through a feeding fan; the cylinder net in the forming area is rotated to make The processed fluff pulp or cotton is fully or stripped on the forming wire under the action of negative pressure fan for secondary molding.

[0065] The main technical parameters of the spunlaced cloth provided by the embodiment of the present invention are:

[0066] 1. Product type...

Embodiment 2

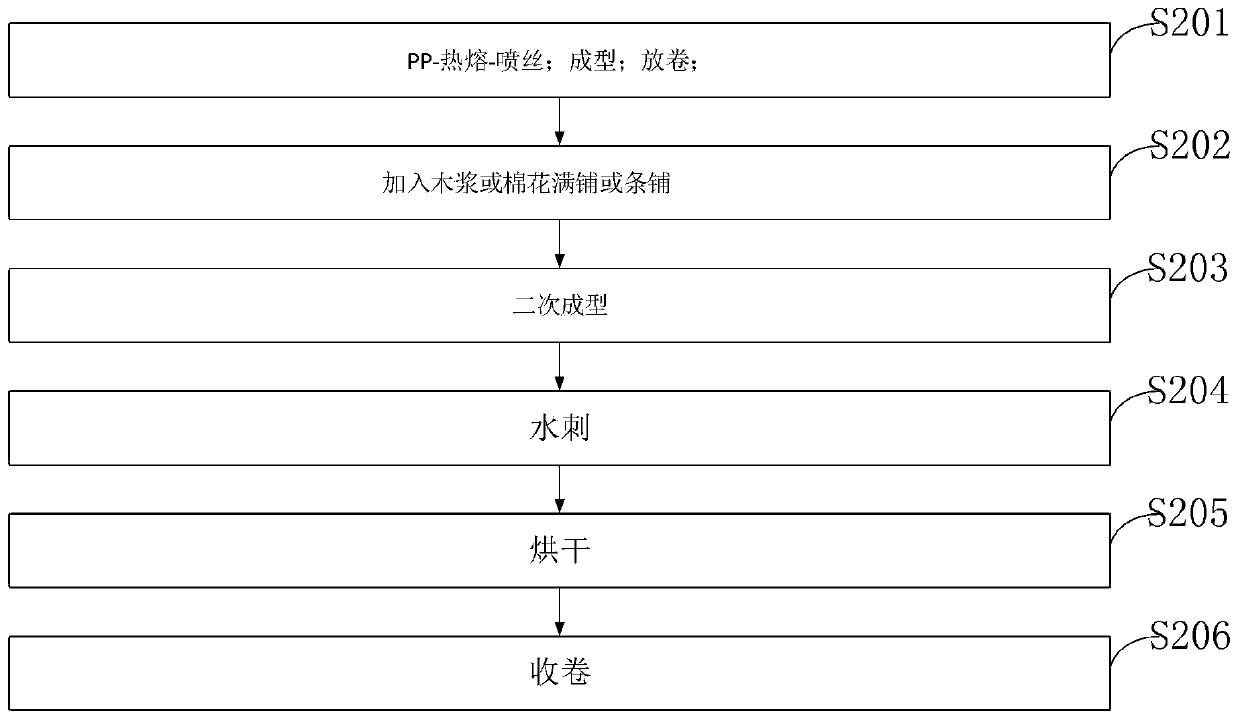

[0083] like figure 2 , the preparation method of the PP spunlace cloth that the embodiment of the present invention provides, comprises:

[0084] S201: PP-hot melt-spinning, forming; unwinding.

[0085] S202: Add 8g-100g of wood pulp or cotton to spread or strip.

[0086] S203: secondary molding.

[0087] S204: Spunlace.

[0088] S205: drying.

[0089] S206: rewinding.

[0090] In step S203, the fluff pulp or cotton is treated with a coarse pulverizer and then a fine pulverizer, and the fluff pulp or cotton is quantified with a fiber collector, and then transported to the first forming area through a feeding fan; The net rotates, so that the processed fluff pulp or cotton is spread or stripped on the forming net under the action of the negative pressure fan for secondary forming.

[0091] The main technical parameters of the PP spunlace cloth provided by the embodiment of the present invention are:

[0092] Product type: wood pulp type spunlace fabric.

[0093] Formin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com