High-bandwidth GaN-based LED light-emitting device with vertical conductive structure and preparation method thereof

A technology of light-emitting devices and conductive structures, applied in the direction of electric solid devices, semiconductor devices, electrical components, etc., can solve the problems of communication lighting, limited bandwidth of LED devices, insufficient response rate, etc., to reduce the chip contact area and enhance the work. Current density, the effect of reducing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

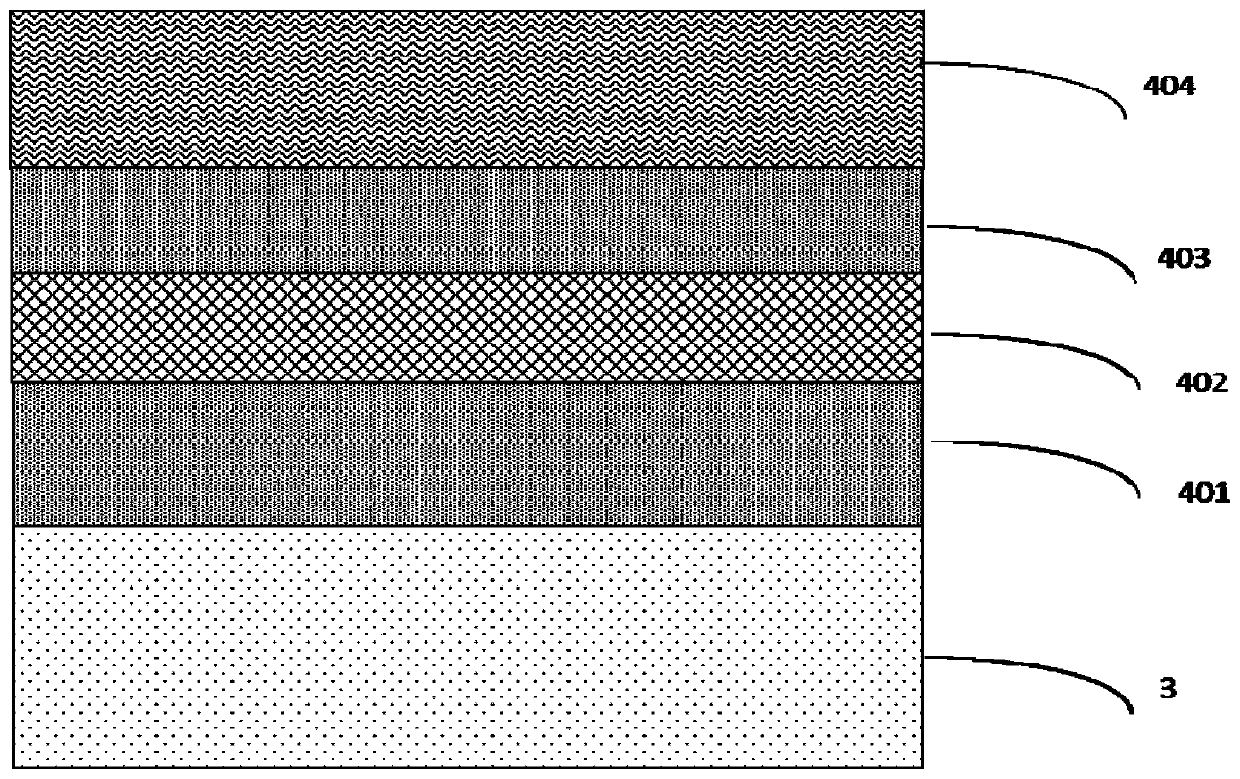

[0030] Such as figure 1 As shown, in this embodiment, MOCVD (metal organic chemical vapor deposition) is used to complete the growth of the LED epitaxial structure 4 on the upper surface of the conductive substrate 3 . The LED epitaxial structure 4 includes, from bottom to top, an N-type doped GaN layer 401 , an InGaN / GaN multi-quantum well active region light-emitting layer 402 , a P-type AlGaN electron blocking layer 403 and a P-type GaN cladding layer 404 .

[0031] The conductive substrate 3 is an m-plane conductive self-supporting GaN homogeneous substrate.

[0032] The N-type doped GaN layer 401 is grown on the upper surface of the conductive substrate 3, and the N-type doping concentration is 1×10 18 cm -3 , the growth temperature is 990°C;

[0033] The InGaN / GaN multi-quantum well active region light-emitting layer 402 is grown on the upper surface of the N-type doped GaN layer 401, by alternately growing InGaN wells and GaN barriers form 5 pairs of multi-quantum w...

Embodiment 2

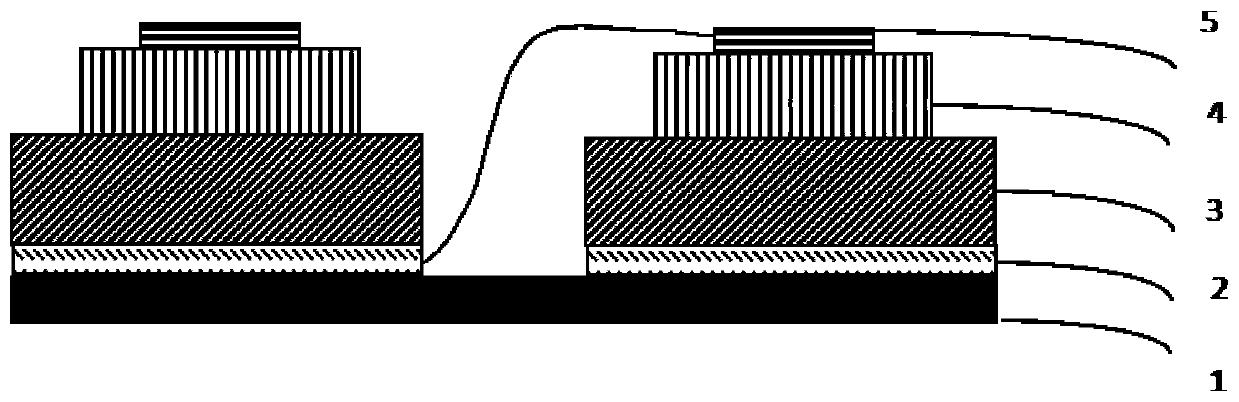

[0047] In this embodiment, the epitaxial growth of the micro-LED with the vertical conductive structure is completed by means of MOCVD. For the epitaxial structure, please refer to figure 1 , the side view of the vertical conductive structure of the LED microarray in series as figure 2 shown. A 3×3 microarray is formed by connecting the N-type electrode and the P-type electrode of a single LED in a head-to-tail series. Its preparation method comprises the following steps:

[0048] 1) Growing an LED epitaxial structure 4 on the upper surface of the conductive substrate 3, the LED epitaxial structure 4 includes an N-type doped GaN layer 401, an InGaN / GaN multi-quantum well active region light-emitting layer 402, and a P-type AlGaN electron blocking layer 403 and a P-type GaN cladding layer 404, the N-type doped GaN layer 401, the InGaN / GaN multiple quantum well active region light-emitting layer 402, the P-type AlGaN electron blocking layer 403 and the P-type GaN cladding la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com