Composite ceramic membrane, preparation method and application thereof

A composite ceramic membrane and ceramic technology, applied in the field of filter membrane, can solve the problems of difficult control of inorganic ceramic membrane pore size, high cost, easy clogging, etc., and achieve the effect of stable filtration effect, stable structure and performance, and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

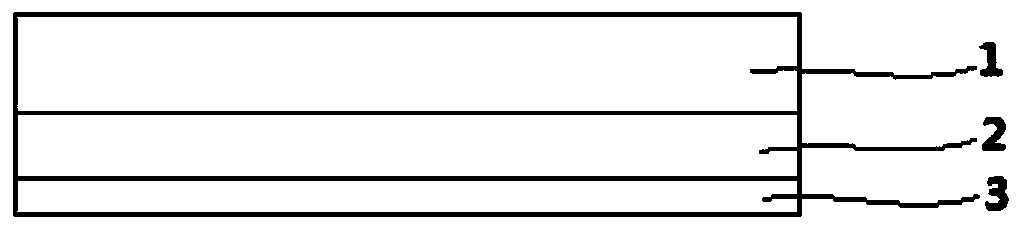

[0031] On the other hand, on the basis of the composite ceramic membrane described above, the embodiment of the present invention also provides a preparation method of the composite ceramic membrane. combine Figure 1 to Figure 4 , the preparation method of the composite ceramic membrane is as follows Figure 5 As shown, it includes the following steps:

[0032] S01: Obtain the green body of the ceramic support layer;

[0033] S02: Coating the ceramic transition layer body slurry on the surface of the ceramic support layer body, and performing the first sintering treatment after drying treatment, to obtain a double-layer ceramic membrane composed of the ceramic transition layer 2 and the ceramic support layer 1 laminated and bonded ;

[0034] S03: coating the separation layer green body slurry on the surface of the ceramic transition layer 2, and then performing a second sintering treatment, so that the separation layer 3 is formed on the surface of the ceramic transition l...

Embodiment 1

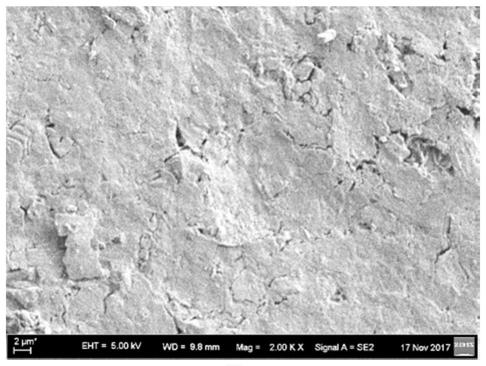

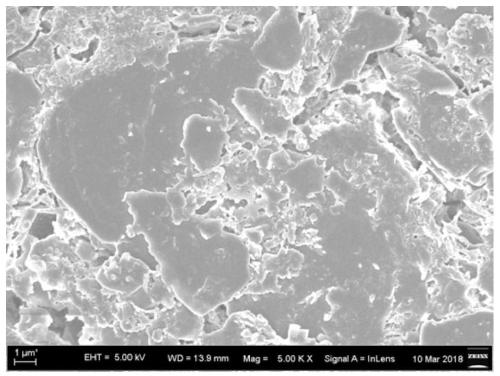

[0053] The embodiment of the present invention provides a composite ceramic membrane and a preparation method thereof. The composite ceramic membrane such as figure 1 As shown, it includes ceramic support layer 1 / ceramic transition layer 2 / separation layer 3 which are stacked in sequence. Wherein, the thickness of the ceramic supporting layer 1 is 500 mm, the average porosity is 38.34%, and the average pore diameter is 318.3 nm; the thickness of the ceramic transition layer 2 is 35 μm, the average porosity is 39.86%, and the average pore diameter is 73.5 nm; The ceramic support layer 1 and the ceramic transition layer 2 are formed by sintering dredged bottom mud; the thickness of the separation layer 3 is 8 μm, the average porosity is 37.89%, and the average pore diameter is 45.3 nm. The composition of the separation layer 3 is copper-iron spinel stone.

[0054] The preparation method of the composite ceramic membrane:

[0055] S11. Preparation of ceramic support layer gree...

Embodiment 2

[0067] The embodiment of the present invention provides a composite ceramic membrane and a preparation method thereof. The composite ceramic membrane such as figure 1 As shown, it includes ceramic support layer 1 / ceramic transition layer 2 / separation layer 3 which are stacked in sequence. Wherein, the thickness of the ceramic support layer 1 is 400 mm, the average porosity is 45.73%, and the average pore diameter is 371.3 nm; the thickness of the ceramic transition layer 2 is 55 μm, the average porosity is 40.34%, and the average pore diameter is 128.3 nm; The ceramic support layer 1 and the ceramic transition layer 2 are formed by sintering dredged bottom mud; the thickness of the separation layer 3 is 5 μm, the average porosity is 28.93%, and the average pore diameter is 41.55 nm. The composition of the separation layer 3 is copper-iron spinel stone.

[0068] The preparation method of the composite ceramic membrane:

[0069] The preparation method of the composite ceramic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com