A medium-high strength insulator material formula and its preparation method

An insulator, high-strength technology, applied in the field of medium and high-strength insulator material formulation and its preparation, can solve the problems of difficult to atomize glaze paste, difficult to control glaze quality, affecting the electrical performance of products and other problems, to improve mechanical strength. and heat and cold properties, improve mechanical strength and electrical properties, improve the effect of process performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] The preparation method of the medium and high strength insulator material of this embodiment includes the following steps:

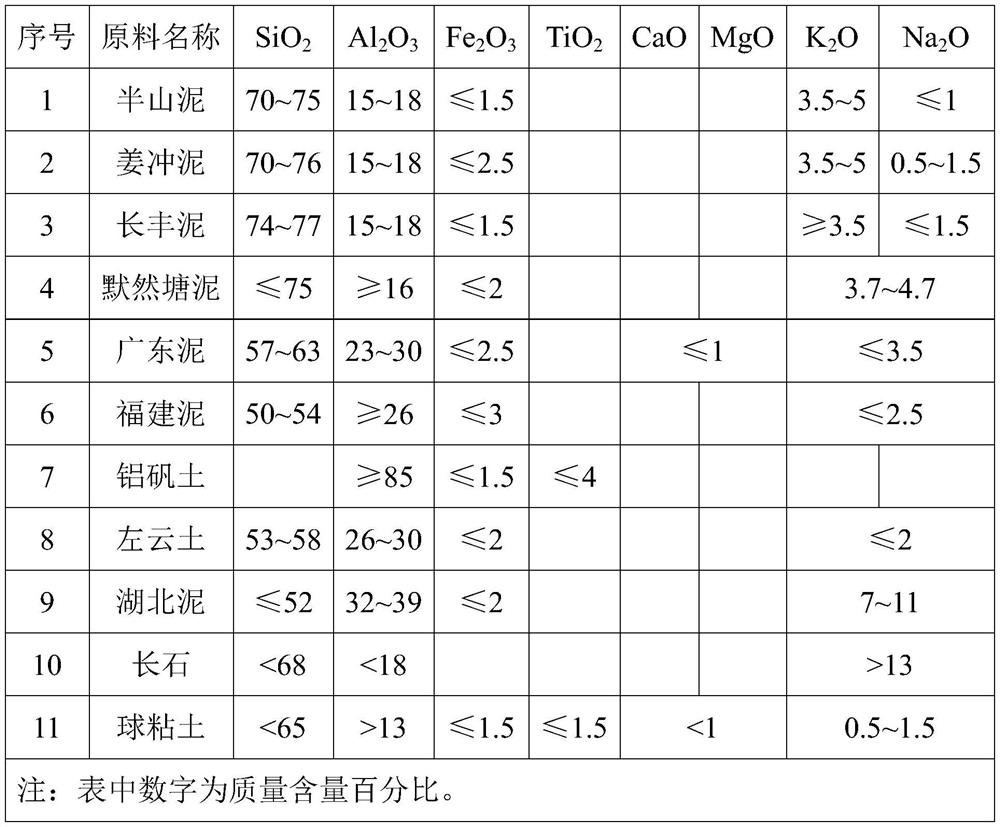

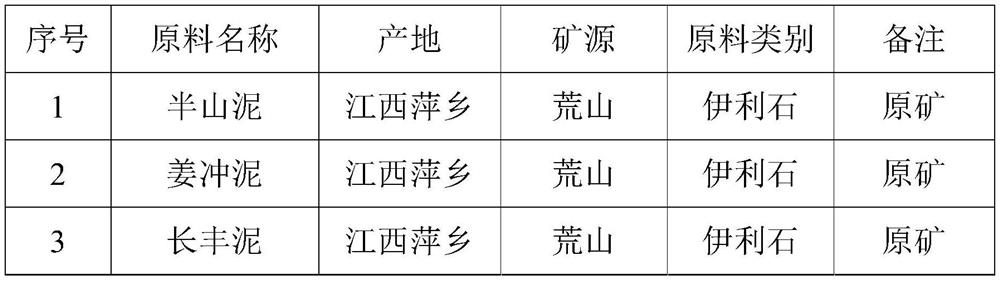

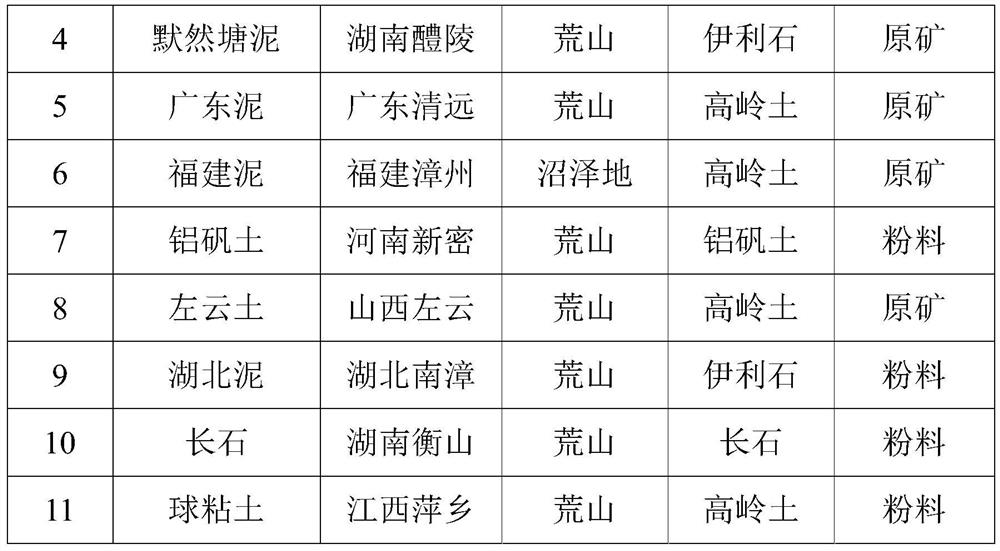

[0056] S1. According to the raw material formula: 12 parts of Banshan mud, 16 parts of Jiangchong mud, 15 parts of Changfeng mud, 12 parts of Morantang mud, 19 parts of Guangdong mud, 5 parts of Fujian mud, 5 parts of bauxite, 10 parts of left cloud soil, Mix 6 parts of Hubei mud, and then transfer it to a ball mill according to the total raw material: ball: water = 1:0.85:0.8 (weight ratio), add water and ball mill for 15 hours, and get a mud with a moisture content of 56%;

[0057] S2, pass the mud prepared in step S1 through a 250-mesh sieve, within 0.3% of the sieve, the content of particles below 10 μm in the sieved mud is 55%, and the content of particles below 20 μm is 70%, then use a magnetic separator at the magnetic field strength Remove iron-containing impurities in a magnetic field of 8000 gauss to obtain clean mud;

[0058] S3, the o...

Embodiment 2

[0066] The preparation method of the medium and high strength insulator material of this embodiment includes the following steps:

[0067] S1. According to the raw material formula: 15.2 parts of Banshan mud, 12.5 parts of Jiangchong mud, 15.3 parts of Changfeng mud, 13 parts of Morantang mud, 21.5 parts of Guangdong mud, 5 parts of Fujian mud, 5.5 parts of bauxite, 7 parts of left cloud clay, 5 parts of Hubei mud are mixed, and then transferred to the ball mill according to the total raw material: ball: water = 1: 1.2: 1.5 (weight ratio), add water ball mill for 8 hours, and get the mud with a moisture content of 65%;

[0068] S2. Pass the mud prepared in step S1 through a 250-mesh sieve, and the remaining 0.1% is within 0.1%. In the sieved mud, the content of particles below 10 μm is 65%, and the content of particles below 20 μm is 85%. Remove iron-containing impurities in the magnetic field to obtain clean mud;

[0069] S3, the obtained mud is filtered and dehydrated to ob...

Embodiment 3

[0077] The preparation method of the medium and high strength insulator material of this embodiment includes the following steps:

[0078] S1. According to the raw material formula: 12 parts of Banshan mud, 13 parts of Jiangchong mud, 15.5 parts of Changfeng mud, 13.5 parts of Morantang mud, 20 parts of Guangdong mud, 6 parts of Fujian mud, 5 parts of bauxite, 9 parts of left cloud clay, Mix 6 parts of Hubei mud, and then transfer it to the ball mill according to the total raw material: ball: water = 1: 1.5: 1.5 (weight ratio), add water and ball mill for 8 hours, and get the mud with a moisture content of 66%;

[0079] S2. Pass the mud prepared in step S1 through a 250-mesh sieve, and the remaining 0.2% is within 0.2%. In the sieved mud, the content of particles below 10 μm is 60%, and the content of particles below 20 μm is 80%. Remove iron-containing impurities in the magnetic field to obtain clean mud;

[0080] S3, the obtained mud is filtered and dehydrated to obtain a mud...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breakdown voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com