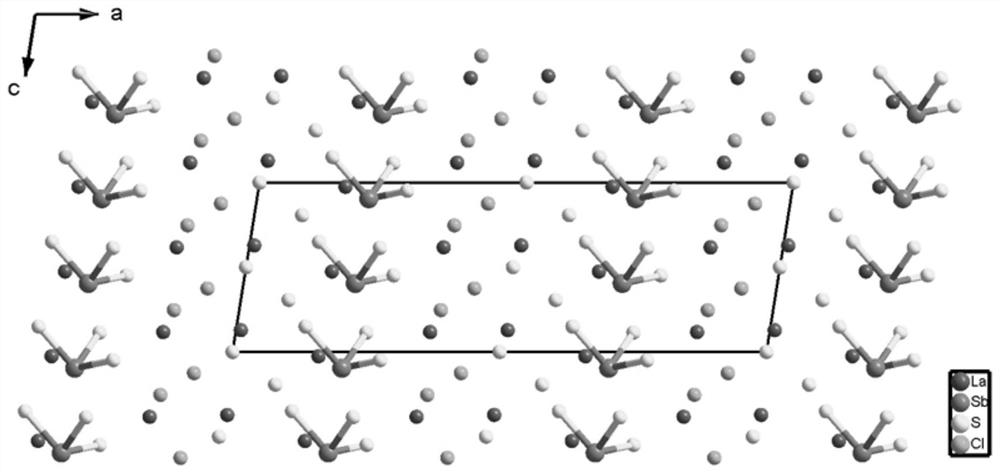

a polar crystal la 3 sbs 5 cl 2 and its preparation method

A polar crystal and crystal technology, applied in the field of polar crystal La3SbS5Cl2 and its preparation, can solve the problems of strong spontaneous polarization and high laser damage threshold at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 6

[0037] The volume fraction of step (1) in the embodiment three is that the nitrogen of 99.99% is replaced by the argon gas that the volume fraction is 99.99%, and the water content and the oxygen content in the water jacket box are all controlled to be 0.08ppm; The embodiment three The degree of vacuum in step (2) is 10 -2 Pa is replaced by 0.8*10 -2 Pa, and the hydrogen-oxygen welding machine is replaced by an acetylene welding machine; the heating rate of the step (3) tubular resistance furnace in embodiment three is replaced by 8 °C / h by 8 °C / h, and the tubular resistance furnace is heated up to 800 ℃ is replaced by heating up to 830 ℃, and the total time of reaction is 96h replaced by 90h; the cooling rate in step (4) in embodiment three is 2.5 ℃ / h replaced by 2 ℃ / h, and the rest are the same as in embodiment three Keep consistent, and polar crystal La with uniform color and particle size can also be obtained 3 Sb 5 Cl 2 polycrystalline powder.

Embodiment 7

[0039] The volume fraction of step (1) in the embodiment three is that the nitrogen of 99.99% is replaced by the helium of the volume fraction of 99.99%, and the water content and the oxygen content in the water jacket box are all controlled to 0.06ppm; The degree of vacuum in step (2) is 10 -2 Pa is replaced by 0.7*10 -2 Pa, and the hydrogen-oxygen welding machine is replaced by an acetylene welding machine; the heating rate of the step (3) tubular resistance furnace in embodiment three is replaced by 12 °C / h, and the tubular resistance furnace is heated up to 800 ℃ is replaced by heating up to 780 ℃, and the total time of the reaction is 96h replaced by 100h; the cooling rate in step (4) in Example 3 is 2.5 ℃ / h replaced by 3.5 ℃ / h, and the rest are the same as in Example 3 Keep consistent, and polar crystal La with uniform color and particle size can also be obtained 3 Sb 5 Cl 2 polycrystalline powder.

[0040] In the specific implementation process of Examples 1-7, lan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com