Separation recycling system and separation recycling process of wide size fraction coal slime

A recovery system and coal slime technology, used in flotation, solid separation, wet separation, etc., can solve the problems of complex sorting process, environmental hazards, high cost, etc., achieve wide application prospects, reduce pollution, and ensure continuous sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

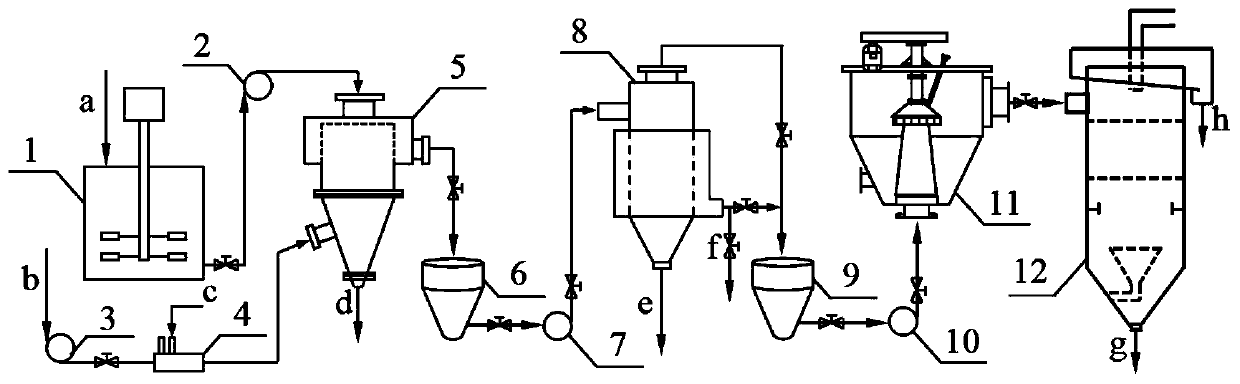

[0034] A specific embodiment of the present invention, such as figure 1 As shown, a sorting and recovery system for wide-grained coal slime is disclosed. A mixing tank 1, a hydraulic flotation machine 5, a three-product cyclone classifying screen 8, a pulp preprocessor 11 and a flotation tank are arranged along the sorting pipeline. Column selection 12; the first feeding pump 2 is arranged between the mixing tank 1 and the hydraulic flotation machine 5; the top of the hydraulic flotation machine 5 is provided with a feed inlet, and the feed inlet is connected with the first feed pump 2, and hydraulic The upper side of the flotation machine 5 is provided with an overflow port, the lower part of the hydraulic flotation machine 5 is a conical structure, the upper side of the conical structure is provided with a fluidization nozzle, and the bottom of the hydraulic flotation machine 5 is provided with an underflow port The first buffer tank 6 is arranged between the hydraulic flota...

Embodiment 2

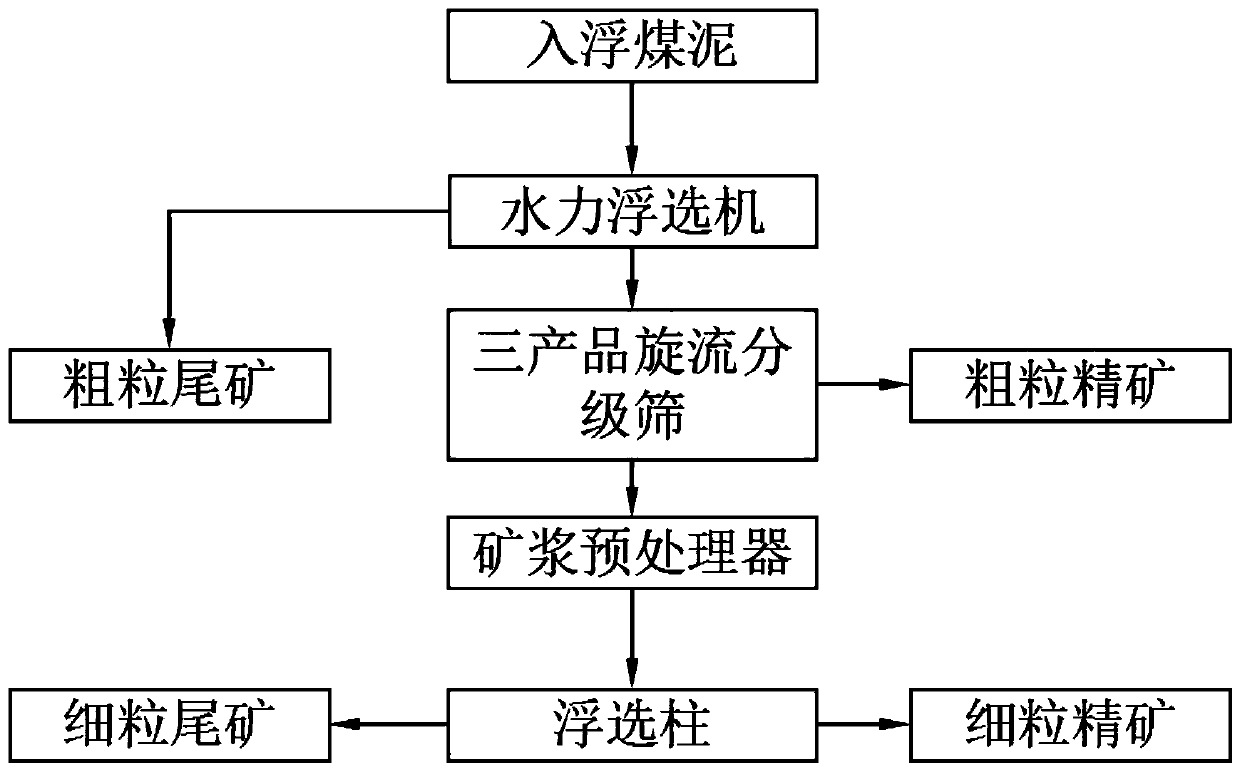

[0044] A specific embodiment of the present invention, such as figure 2 As shown, a sorting and recycling process of wide-grained coal slime is disclosed. For example, the device provided in Example 1 is used. The sorting and recycling process includes the following steps:

[0045] Step 1: Feed the floating coal slime a into the mixing tank, add water and collector to the mixing tank for the floating coal slime and stir to make a slurry, after mixing evenly, the first feeding pump continuously, uniformly and stably feeds the hydraulic Flotation machine;

[0046] Preferably, the pulp concentration in step 1 is 400-600g / L. If the pulp concentration is too low, the processing capacity is too low, the consumption of chemicals is large, and the production cost is high; if the pulp concentration is too high, the resistance between particles will also increase, which is not conducive to disturbing the settlement. Increase the ash content of clean coal and deteriorate the separatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com