Grille trash-holding treatment system

A technology of pollution treatment and grid, which is applied in the field of grid pollution control treatment system, can solve the problems of unclean washing, clogging and clogging of the screen, and achieve the effect of improving the effect of internal flushing and strengthening the effect of reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

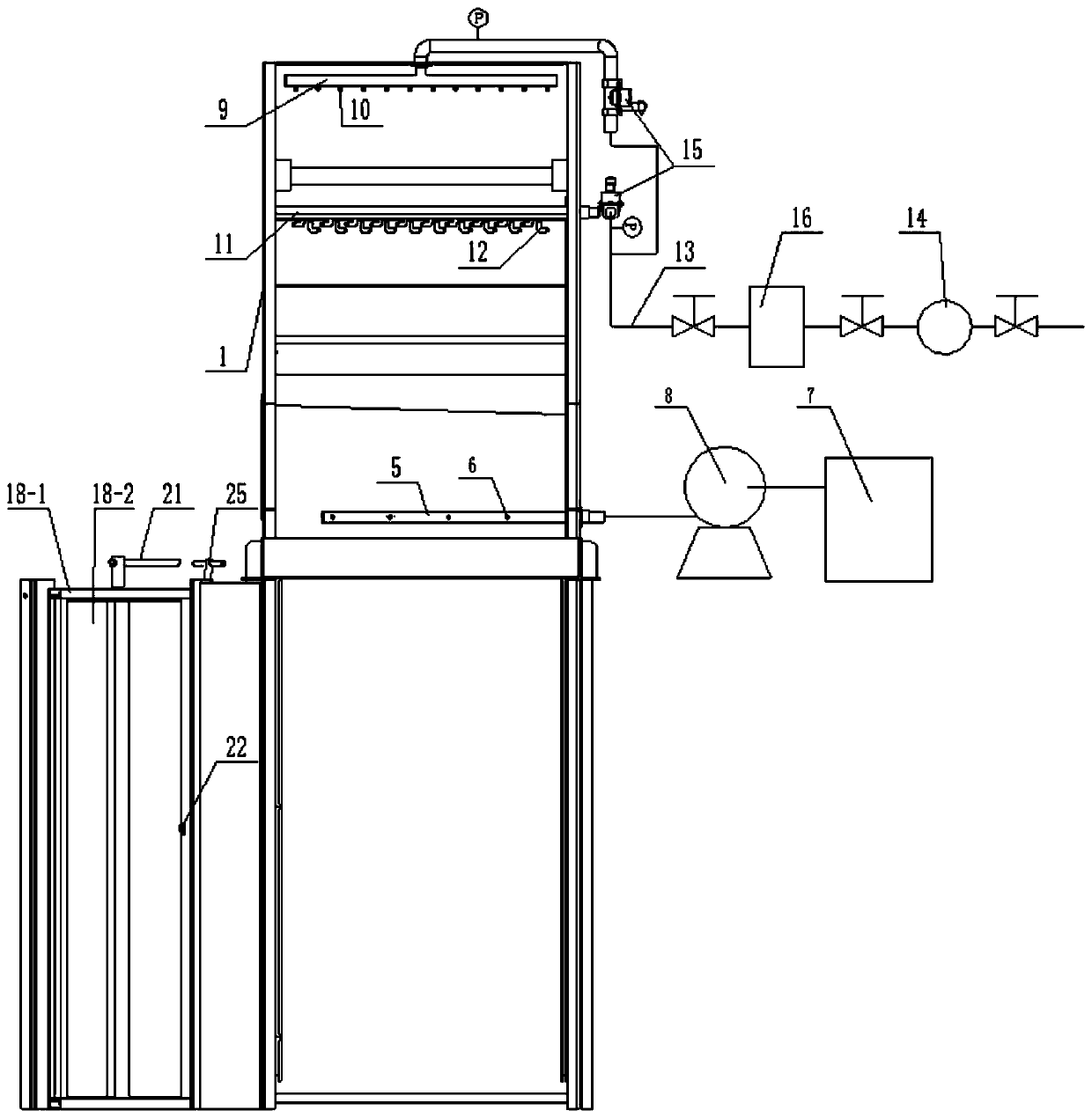

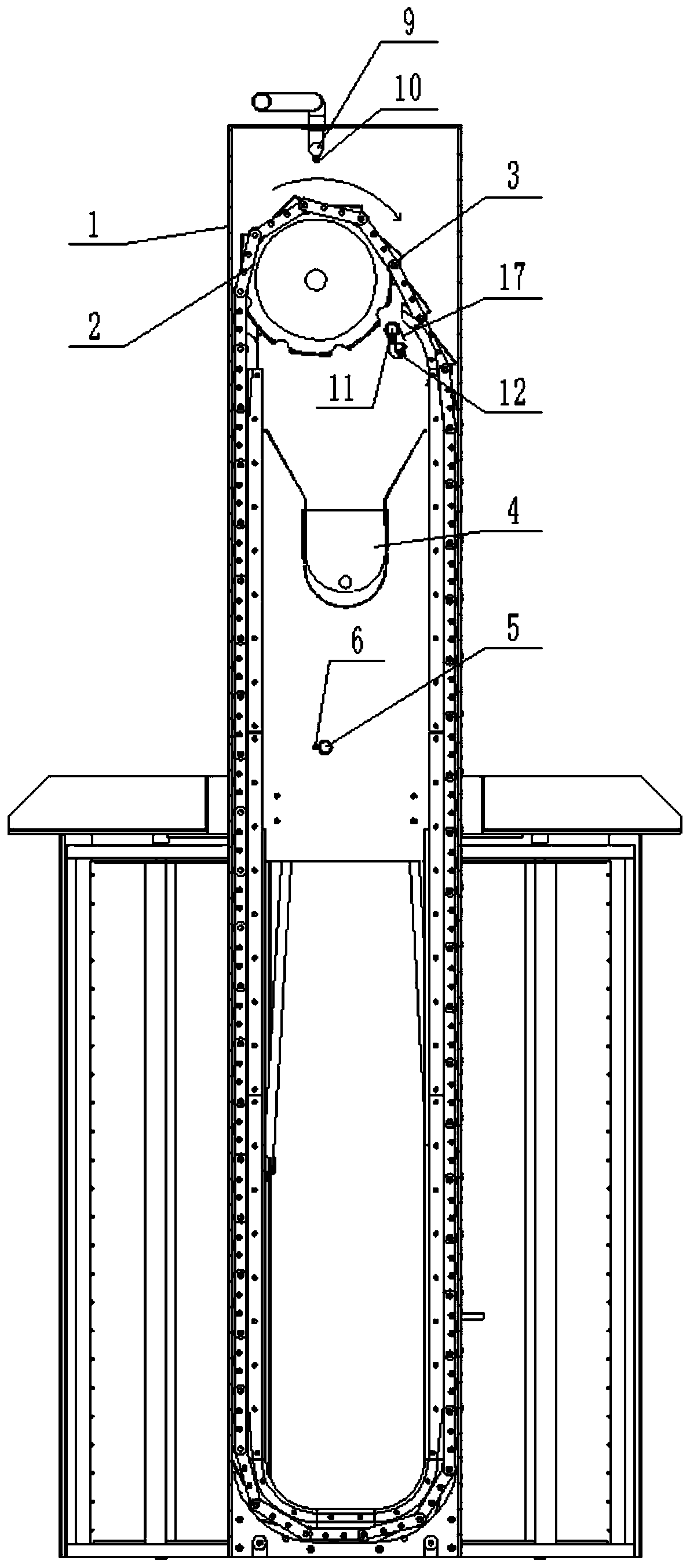

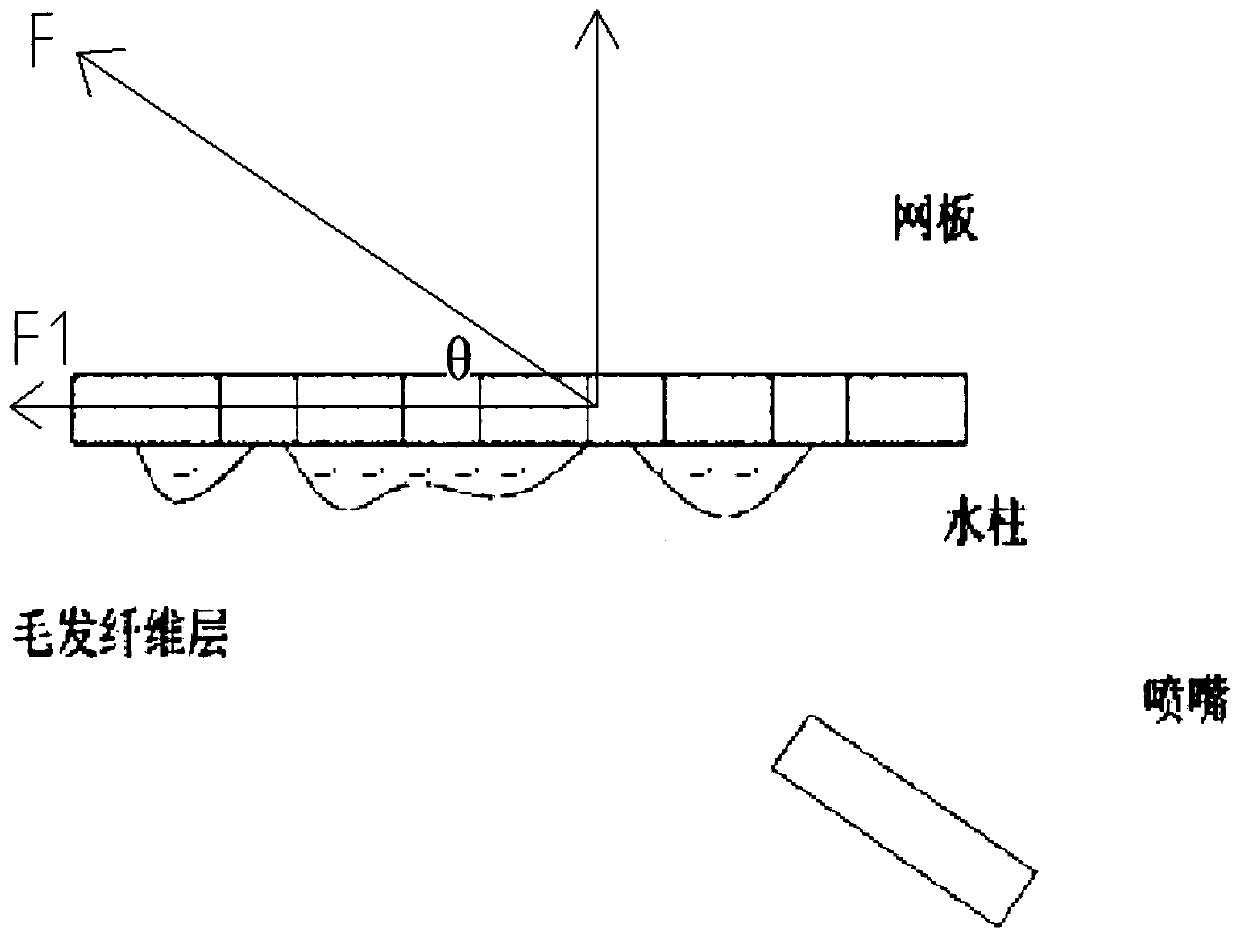

[0043] Such as Figure 1-Figure 2 As shown in the figure, a grid trash removal treatment system includes a grid decontamination machine and a trash gate; the grid decontamination machine is installed on the grid canal, and the trash gate is installed at In the grid channel; the grid decontamination machine includes a driving device, a frame 1, a traction chain 2 installed along the inner circumference of the frame 1, a grid net plate 3 with a lifting step installed on the traction chain 2, Slag collecting tank 4, electrical control cabinet; oxalic acid flushing assembly, external flushing assembly, internal flushing assembly and high-pressure water source are installed in the grid decontamination machine, and the oxalic acid flushing assembly includes oxalic acid flushing main pipe 5, oxalic acid flushing nozzle 6, and oxalic acid flushing assembly The dosing box 7 and the dosing pump 8 connected by the flushing main pipe 5, the outer flushing assembly includes the outer flush...

Embodiment 2

[0052] On the basis of Embodiment 1, in a preferred embodiment, the gate frame 18 - 1 is not provided with the gate handle 21 , the gate block 22 , the handle 24 of the gate block and the handle 25 . The pivot at the upper end of the gate plate 18-2 is connected to a motor reducer, and the motor reducer is connected to a PLC control system. The motor reducer can be controlled by the PLC control system, and the rotation and opening of the gate plate 18-2 and the opening degree control can be realized by the motor reducer.

Embodiment 3

[0054] On the basis of Example 1, such as Figure 8-Figure 12 , the present invention also includes a grille device 26 that can increase the flow of water, and is arranged between the trash gate and the straight deflector 19 . The grid device includes a set of screen frames 27 and a brush cleaning system installed on both sides of the grid channel; the brush cleaning system includes a brush movement mechanism and a driving mechanism; the screen frame 27 is a rectangular frame , the screen frame 27 is provided with a bottom water sealing plate 28, a top water sealing plate 29, and a water-passing mesh plate 30, and the bottom water sealing plate 28 and the top water sealing plate 29 are respectively welded on the bottom and top of the frame, and there are several The water-passing screen 30 is filled and welded with the screen frame 27 as a whole. The two long sides of the screen frame 27 are provided with brush reciprocating waist-shaped grooves 31, and the brush movement mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com