Water sticker gloss high-hydroxy acrylate resin and preparation method thereof

A technology of high-hydroxy acrylic acid and hydroxy acrylic acid, which is applied in the field of resin for coatings, can solve the problems of easy shrinkage, small orange lines, poor leveling, etc., and achieve improved fullness, improved adhesion, good gloss and fullness degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

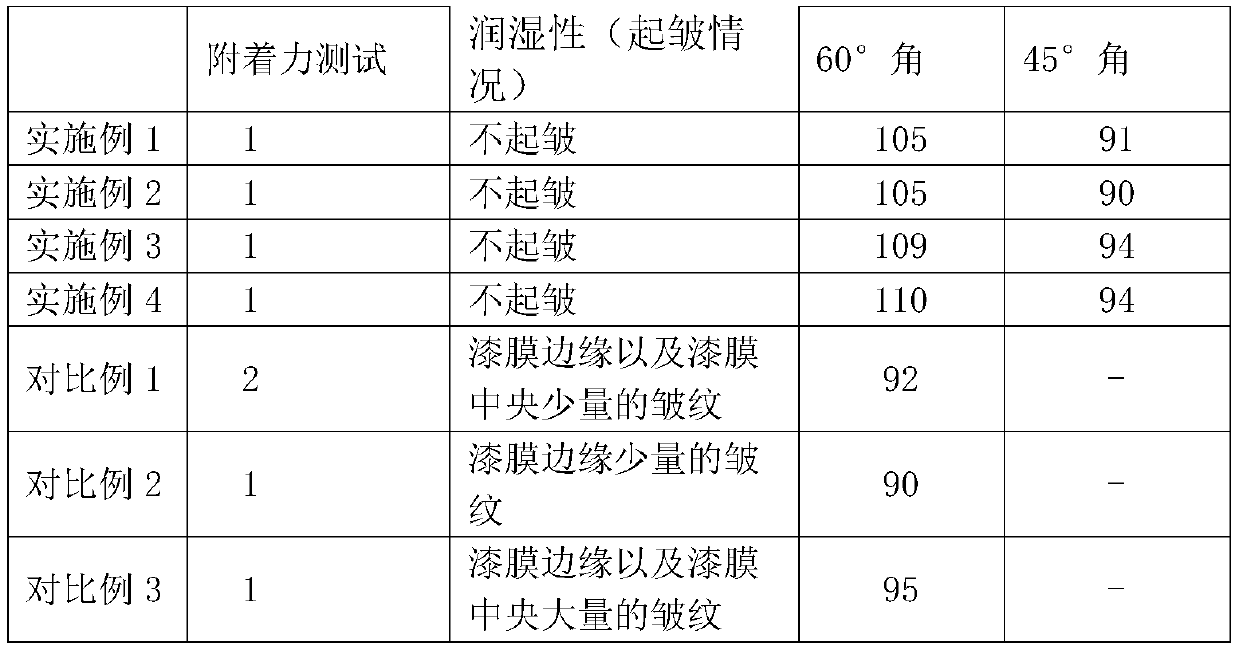

Examples

Embodiment 1

[0026] Step 1: Add 15g of benzene into the reaction vessel and heat to 65-70°C; add 2g of dodecyl methacrylate, 15g of hydroxypropyl methacrylate, 40g of styrene, 10g of methyl methacrylate, 6g of methyl Butyl acrylate and 2g vinyltrimethoxysilane were mixed uniformly to obtain the monomer phase;

[0027] 10g of benzene and 1.875g of azobisisobutyronitrile were mixed to obtain an initiator solution;

[0028] Step 2: Add the monomer phase and 70-80% initiator solution dropwise to the reaction vessel in step 1 at the same time, and add dropwise for 3 hours under the protection of an inert gas;

[0029] Step 3: Add the remaining initiator into the reaction vessel at one time, keep it warm at 70-75°C for 1 hour, and finish the reaction.

Embodiment 2

[0031] Step 1: Add 18g of benzene into the reaction vessel and heat to 65-70°C; add 4g of dodecyl methacrylate, 15g of hydroxypropyl methacrylate, 30g of styrene, 12g of methyl methacrylate, 8g of methyl Butyl acrylate and 3g vinyltrimethoxysilane were mixed uniformly to obtain the monomer phase;

[0032] 10g of benzene and 2.16g of azobisisobutyronitrile were mixed to obtain an initiator solution;

[0033] Step 2: Add the monomer phase and 70-80% initiator solution dropwise to the reaction vessel in step 1 at the same time, and add dropwise for 3 hours under the protection of an inert gas;

[0034] Step 3: Add the remaining initiator into the reaction vessel at one time, keep it warm at 70-75°C for 2 hours, and finish the reaction.

Embodiment 3

[0036] Step 1: Add 20g of benzene into the reaction vessel and heat to 65-70°C; add 3g of dodecyl methacrylate, 12g of hydroxypropyl methacrylate, 35g of styrene, 11g of methyl methacrylate, 7g of methyl Butyl acrylate and 2g vinyltrimethoxysilane were mixed uniformly to obtain the monomer phase;

[0037] 10g of benzene and 2.16g of azobisisoheptanonitrile were mixed to obtain an initiator solution;

[0038] Step 2: The monomer phase and 70-80% initiator solution are simultaneously added dropwise to the reaction vessel of step 1, and added dropwise for 2 hours under the protection of an inert gas;

[0039] Step 3: Add the remaining initiator into the reaction vessel at one time, keep it warm at 70-75°C for 2 hours, and finish the reaction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com