Biodegradable green printing ink binder, ink and preparation method thereof

A technology for ink binders and printing inks, applied in inks, household utensils, applications, etc., can solve problems such as poor performance of inks, threats to the ecological environment, and difficult natural degradation of inks, and achieve improved gloss and drying performance and outstanding resources. Effect of reproducibility, excellent process flow properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

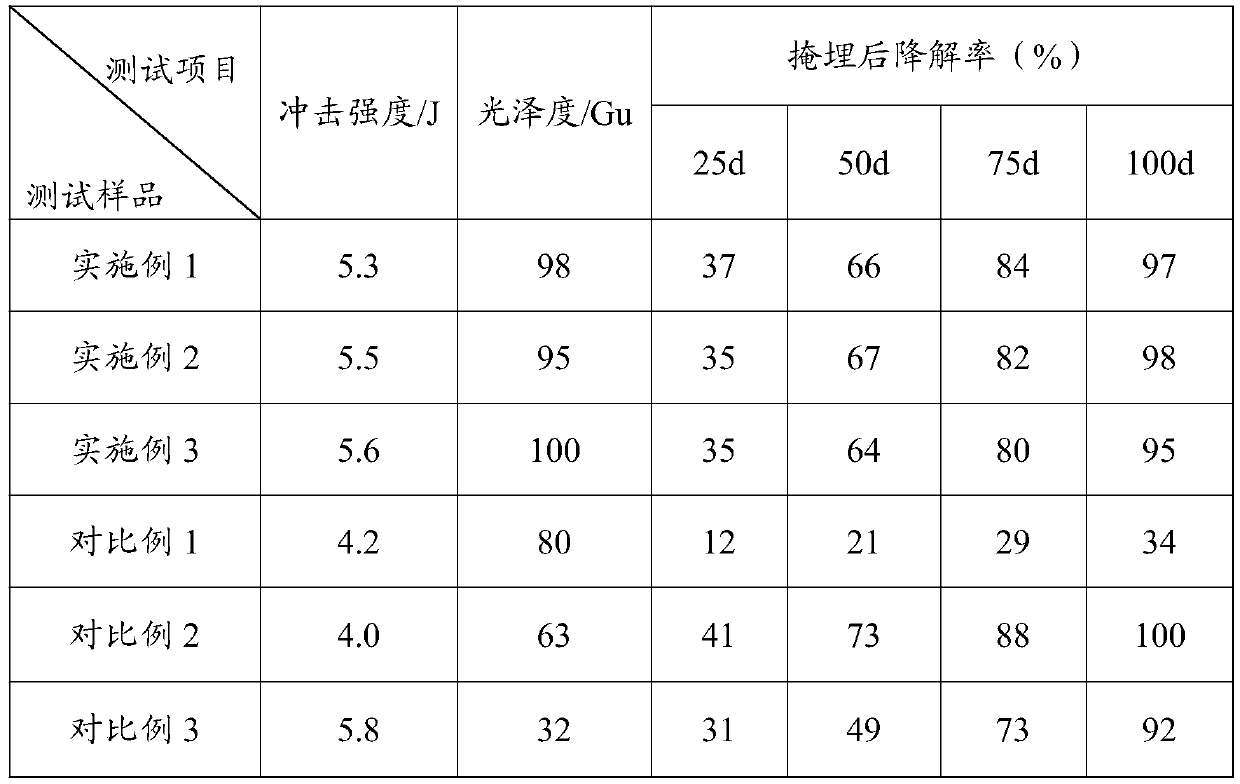

Examples

Embodiment 1

[0028] This embodiment provides a biodegradable green printing ink binder, which includes polylactic acid microspheres with an average particle size of 5 μm.

[0029] The raw material of polylactic acid microspheres is lactic acid, which can be obtained by fermentation of starch extracted from corn, wheat, cassava and other plants. Therefore, polylactic acid has significant environmental friendly characteristics in the whole cycle of synthesis, manufacture, use and disposal , At the same time, because the raw material of polylactic acid microspheres can be extracted from natural plants, it can get rid of the dependence on petroleum to the greatest extent, and has outstanding resource renewability.

[0030] The ink vehicle described in this embodiment has a uniform particle size, so that the ink material containing the ink vehicle has an excellent developing effect.

[0031] This embodiment also provides a method for preparing the biodegradable green printing ink binder, which ...

Embodiment 2

[0037]This embodiment provides a biodegradable green printing ink binder, which includes polylactic acid microspheres with a particle size of 8 μm.

[0038] The ink vehicle described in this embodiment has a uniform particle size, so that the ink material containing the ink vehicle has an excellent developing effect.

[0039] This embodiment also provides a method for preparing the biodegradable green printing ink binder, which includes the following steps:

[0040] S1. Preparation of polylactic acid seed microspheres, dehydration condensation of lactic acid aqueous solution at 240° C. to obtain polylactic acid seed microspheres.

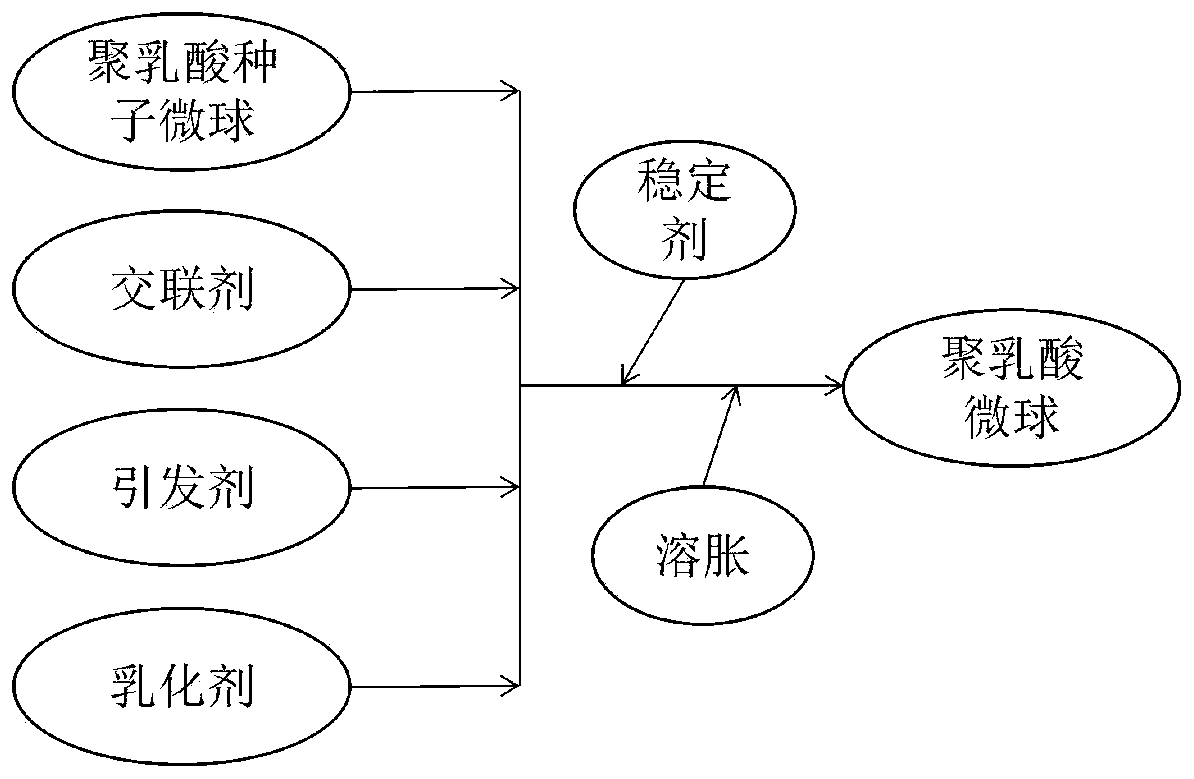

[0041] S2. Prepare polylactic acid microspheres, mix the polylactic acid seed microspheres with crosslinking agent, initiator, and emulsifier in proportion to obtain a premix, add a stabilizer to the premix, and perform a swelling reaction. Obtain polylactic acid microsphere ink binder with controllable particle size, such as figure 1 shown. In t...

Embodiment 3

[0045] This embodiment provides a biodegradable green printing ink binder, which includes polylactic acid microspheres with a particle size of 8 μm.

[0046] The ink vehicle described in this embodiment has a uniform particle size, so that the ink material containing the ink vehicle has an excellent developing effect.

[0047] This embodiment also provides a method for preparing the biodegradable green printing ink binder, which includes the following steps:

[0048] S1. Prepare polylactic acid seed microspheres, dehydrating and condensing the lactic acid aqueous solution at 200° C. to obtain polylactic acid seed microspheres;

[0049] S2. Prepare polylactic acid microspheres. After mixing the polylactic acid seed microspheres with crosslinking agent, initiator, and emulsifier in proportion, a premix is obtained. Add an appropriate amount of stabilizer to the premix, and the swelling reaction , to obtain polylactic acid microsphere ink binder with controllable particle size...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com