Method for preparing artificial joint prosthesis by using 3D printing technology

An artificial joint and 3D printing technology, applied in 3D printing, prosthesis, manufacturing tools, etc., can solve the problems of prolonging operation time, poor shape fitting, aggravating local trauma, etc., and achieve mature preparation technology, weak stress shielding effect, Porosity controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1 Artificial joint prosthesis of the present invention

[0034] One, the structure of artificial joint prosthesis of the present invention

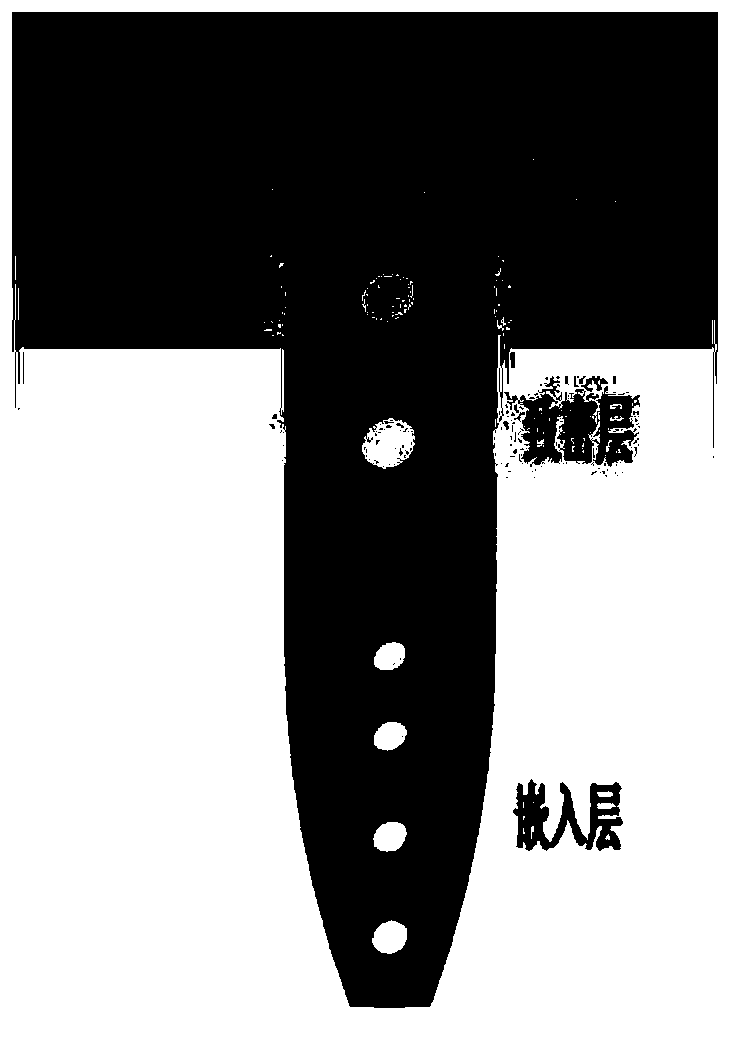

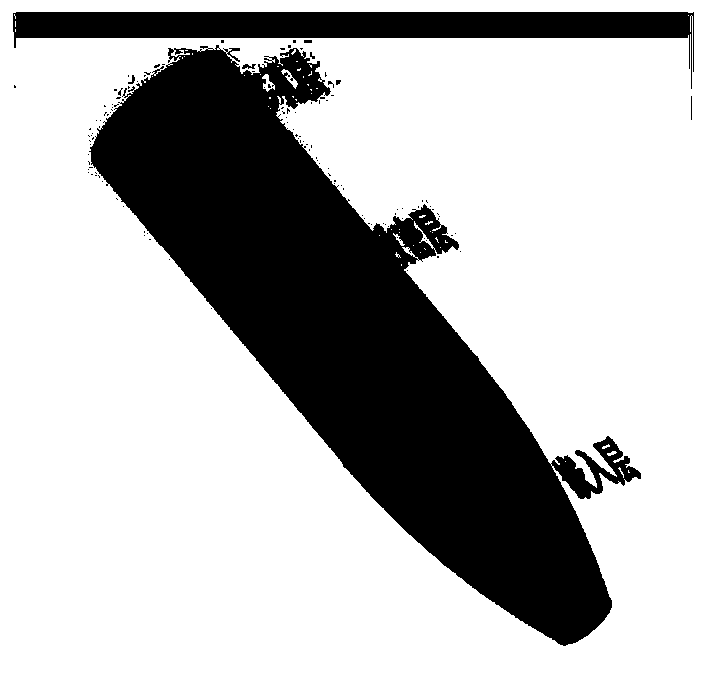

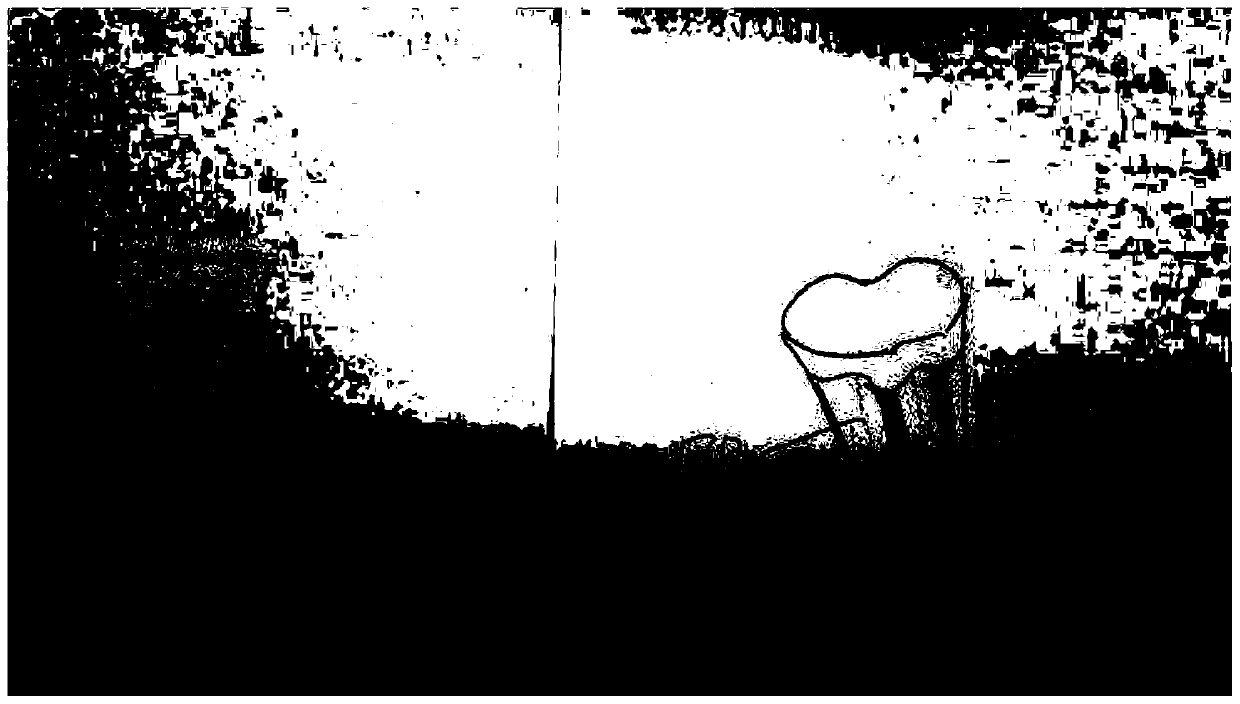

[0035] The artificial joint prosthesis with bionic function of the invention is composed of a porous layer, a compact layer and an embedded layer. Such as Figure 1-Figure 3 As shown, among them, figure 1 and figure 2 Indicates the positional relationship, proportional relationship between different layers and the internal structure of each layer, image 3 Indicates the shape of the artificial joint that is actually produced, and the size of the artificial joint can be adjusted according to the specific conditions of the patient.

[0036] 1. Porous layer

[0037] The porous layer is the contact part of the articular surface, designed as a porous structure, and the material used is nano-hydroxyapatite / polyamide 66. The porosity of the porous structure is 85% to 90%, the inner diameter of the pores is 200 to 350 μm,...

experiment example 1

[0050] Experimental Example 1: Different Pore Sizes of Porous Layers to Cultivate Chondrocyte Layers

[0051] The artificial joint prosthesis prepared by the method of the present invention is taken, inoculated with cells, and cultured.

[0052] Experimental results show that the specific porosity and inner diameter in the porous structure of the porous layer of the present invention are beneficial to the cultivation of the chondrocyte layer.

experiment example 2

[0053] Experimental Example 2 Application of Artificial Joint Prosthesis in Reconstruction of Large Segmental Bone Defect

[0054] The artificial joint prosthesis prepared by the method of the present invention is used for bone defect reconstruction.

[0055] The experimental results show that the cultivation of the chondrocyte layer on the porous structure of the present invention is beneficial to the realization of the motor function; the macroporous structure added to the dense layer is filled with autologous bone tissue, so that the artificial joint prosthesis and the surrounding bone tissue "grow" as one, which can realize Good bone tissue fusion, autologous bone tissue vascularization and better supporting function.

[0056] In summary, the present invention provides a method for preparing an artificial joint prosthesis using 3D printing technology. The present invention uses 3D printing technology to "tailor-made" the artificial joint prosthesis with bionic functions to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com