Porous polyether-ether-ketone skull substitute and manufacturing method thereof

A technology of polyether ether ketone and substitutes, which is applied in the field of porous polyether ether ketone skull substitutes and its manufacture, can solve the problems of heat sensitivity of titanium alloy substitutes, damage of material parts, unfavorable bone growth, etc., and achieve improved mechanical properties and biological activity, to achieve the effect of biological immobilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0018] A porous polyether ether ketone skull substitute such as figure 1 As shown, the edge contour and solid model of the skull substitute were obtained by reverse calculation of computed tomography of the patient's head, and the edge contour of the skull substitute was in good agreement with the autologous skull defect;

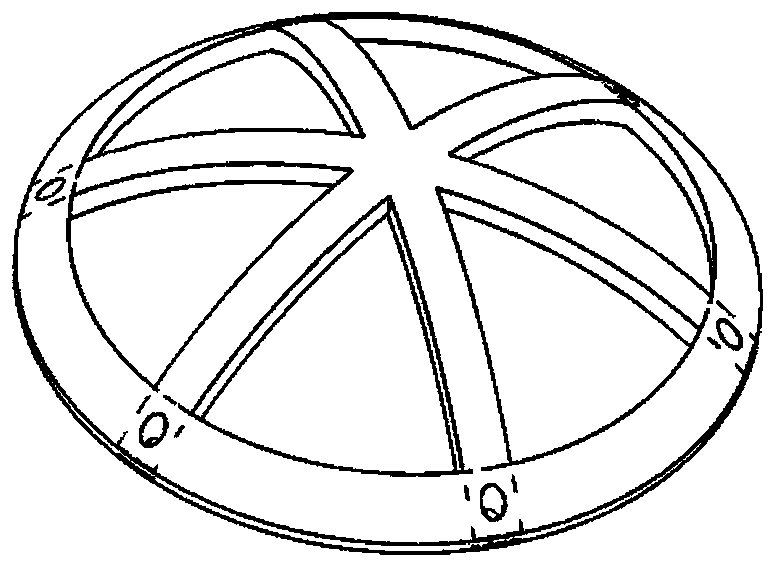

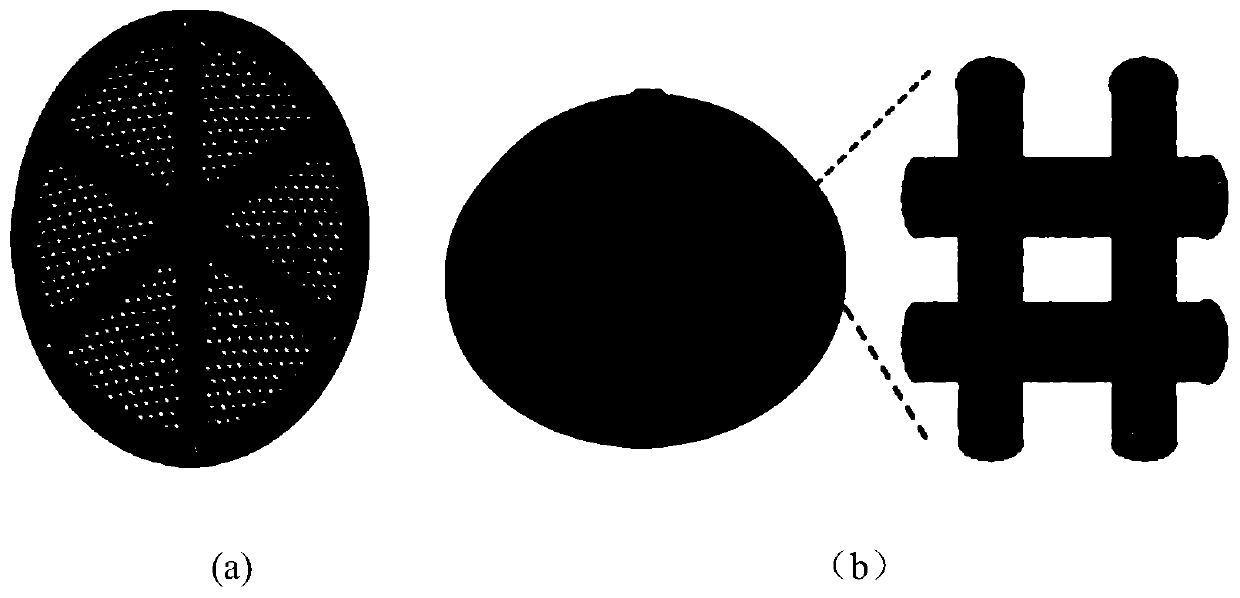

[0019] The described skull substitute includes main body solid reinforcement and porous structure, such as figure 2 As shown, the main entity is an arc-shaped porous structure with solid reinforcing ribs, which are obtained through topology optimization; the porous structure includes a braided structure, a through hole, a composite of a braided structure and a through hole, wherein The minimum line width of the braided structure is 0.2-0.6mm, the line spacing is 0.4-2mm, the included angle of each line is 5-180° adjustable, the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com