Waterborne environment-friendly insulation deep-drawing ink and preparation method thereof

A deep-drawing, water-based technology, applied in the field of water-based environmentally friendly insulating deep-drawing ink and its preparation, can solve the problems of human body injury and environmental pollution, achieve strong adhesion, low VOC content, and achieve the effect of protecting the human body and the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The embodiment of the present invention also provides a preparation method of the above-mentioned water-based insulating deep drawing ink, the method comprising the following steps:

[0023] Step 1, adding organic silicon resin, inorganic nano-ceramic resin, anti-wear additive, defoamer, leveling agent, dispersant, wetting agent, After stirring dimethylethanolamine and water evenly, use a three-roll machine or a sand mill to grind to a fineness of <10 μm to obtain a ground mixture;

[0024] In step 2, the temperature of the ground mixture obtained in step 1 is lowered to normal temperature, and then filtered to obtain water-based insulating deep-drawing ink.

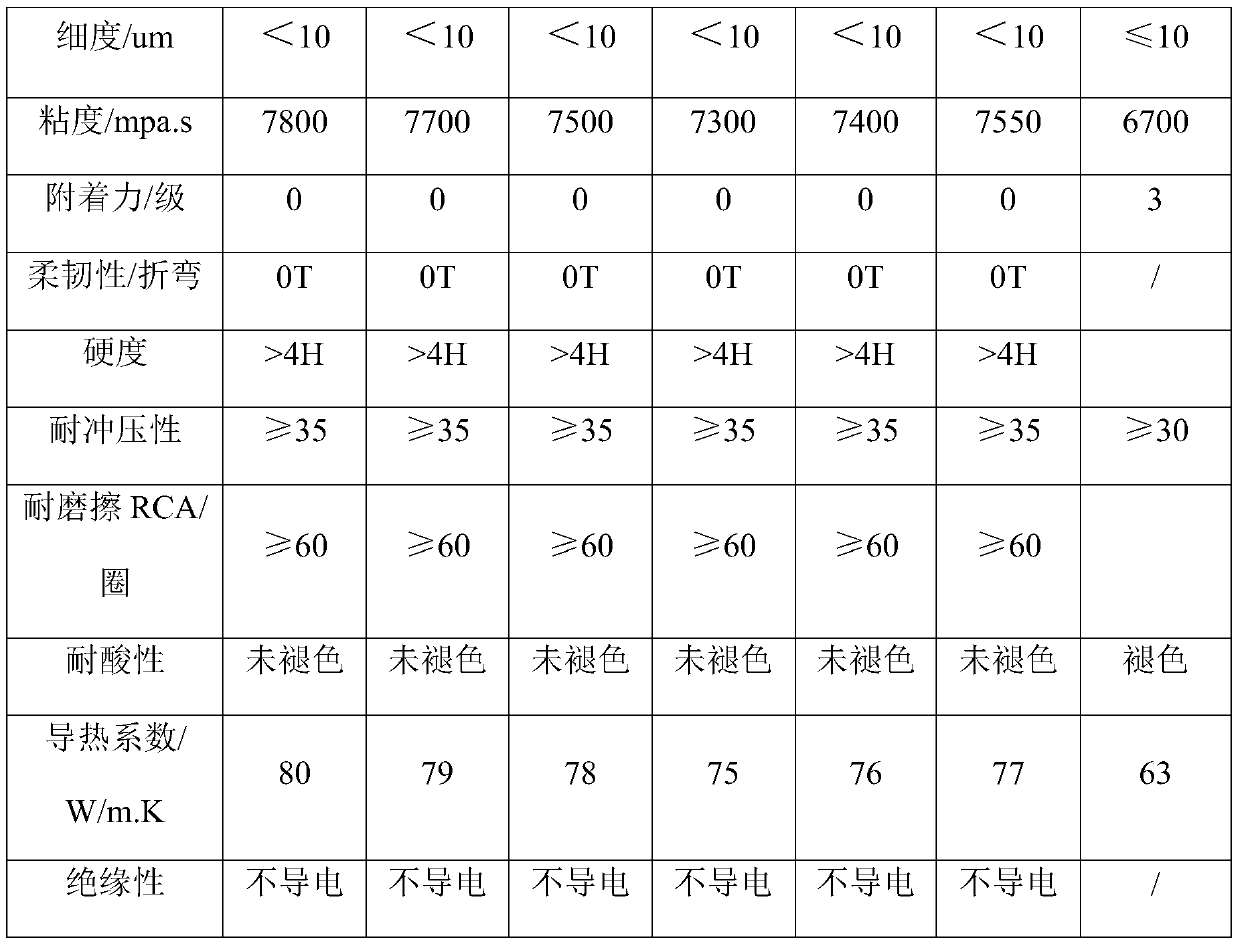

[0025] By adopting the above scheme, by adding organic silicon resin, inorganic nano-ceramic resin, wear-resistant additives and dimethylethanolamine to the formula forming the paint film, the hardness of the paint film (hardness pencil 5-6H), flexibility (bending / bending 0T), abrasion resistance (RCA greater tha...

Embodiment 1

[0027] A water-based environmental protection insulating deep drawing ink, the ink includes the following raw materials in weight percentage: 50% of water-based epoxy modified saturated polyester resin, 8% of water-based silicone resin, 8% of inorganic nano-ceramic resin, methyl etherified amino 12% resin, 5% polyethylene wax powder, 1.2% silicone defoamer, 0.4% silicone leveling agent, 2% modified polyurethane, 1% acetylenic alcohol, 0.8% dimethylethanolamine, and the rest is water .

[0028] The preparation method of the above-mentioned water-based environmental protection insulating deep drawing ink is realized through the following steps:

[0029] Step 1, add organic silicon resin, inorganic nano-ceramic resin, wear-resisting additive, defoamer, leveling agent, dispersant, wetting agent, dimethylformamide in sequence at a stirring rate of 600r / min to the polyester resin Glyethanolamine and water, after stirring evenly, use a three-roll machine or a sand mill to grind to a...

Embodiment 2

[0032] A water-based environmental protection insulating deep drawing ink, the ink includes the following raw materials in weight percentage: 50% of water-based epoxy modified saturated polyester resin, 8% of water-based silicone resin, 8% of inorganic nano-ceramic resin, methyl etherified amino 12% resin, 5% polyethylene wax powder, 1.2% silicone defoamer, 0.4% silicone leveling agent, 2% modified polyurethane, 1% acetylenic alcohol, 0.8% dimethylethanolamine, and the rest is water .

[0033] The preparation method of the above-mentioned water-based environmental protection insulating deep drawing ink is realized through the following steps:

[0034] Step 1, adding silicone resin, anti-wear additives, defoamers, leveling agents, dispersants, wetting agents, dimethylethanolamine and water to the polyester resin in turn at a stirring rate of 400r / min, After stirring evenly, use a three-roll machine or a sand mill to grind to a fineness of <10 μm to obtain a ground mixture;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com