Fiber web for gas sensor, manufacturing method thereof, and gas sensor including same

一种气体传感器、制造方法的技术,应用在纤维网领域,能够解决难以应用等问题,达到防止检测性能的变化、提高灵敏度、优秀纺丝性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

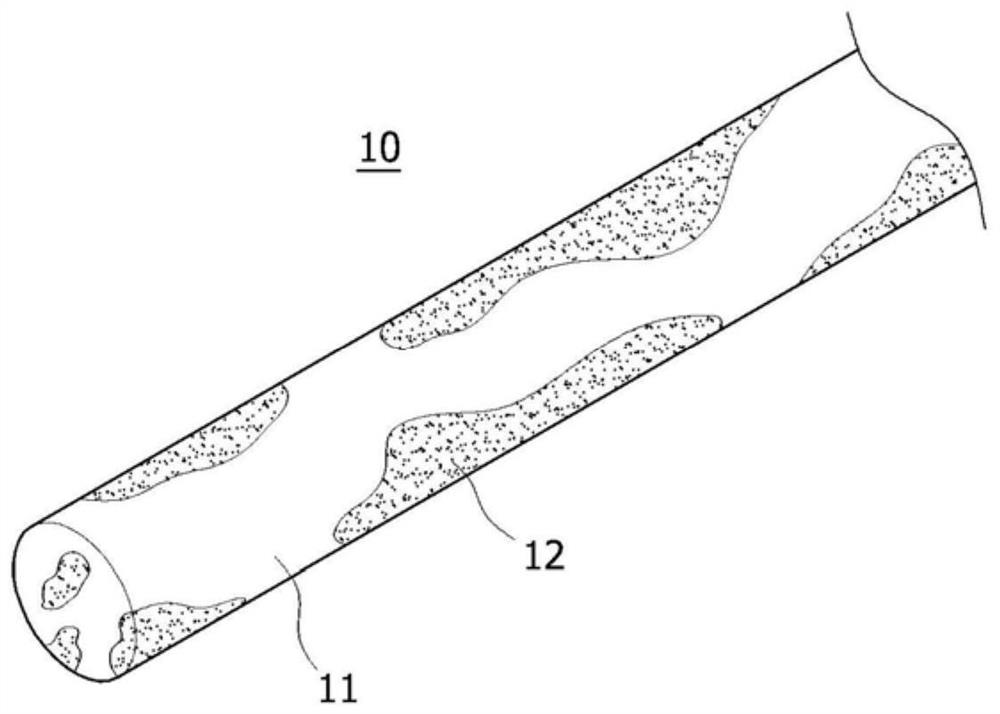

[0085] First, 180 g of dimethylacetamide (DMAC) as a solvent and 32 g of polyvinylidene fluoride (Arkema, Kynar 761) as a fiber-forming component were dissolved at 80°C for 6 hours using a magnetic bar. , a fiber-forming component solution was prepared.

[0086] Then, in order to prepare the dispersion liquid that comprises sensory component, after preparing dimethylacetamide (DMAC) 60g as dispersion medium, in it, mix lead acetate trihydrate (Sigma Aldrich (Sigmaaldrich (Sigmaaldrich) company, weight average molecular weight 379.33) 96g, At a temperature of 80°C, using a magnetic rod for 1 hour, a dispersion liquid in which lead acetate trihydrate was melt-dispersed in a dispersion medium was prepared. Then, after mixing the fiber-forming component solution and the dispersion liquid, the fiber-forming component solution and the dispersion liquid were mixed using a bar magnet at a temperature of 60° C. for 2 hours.

[0087] Centrifuge the prepared mixed solution at 3000 rpm f...

Embodiment 2

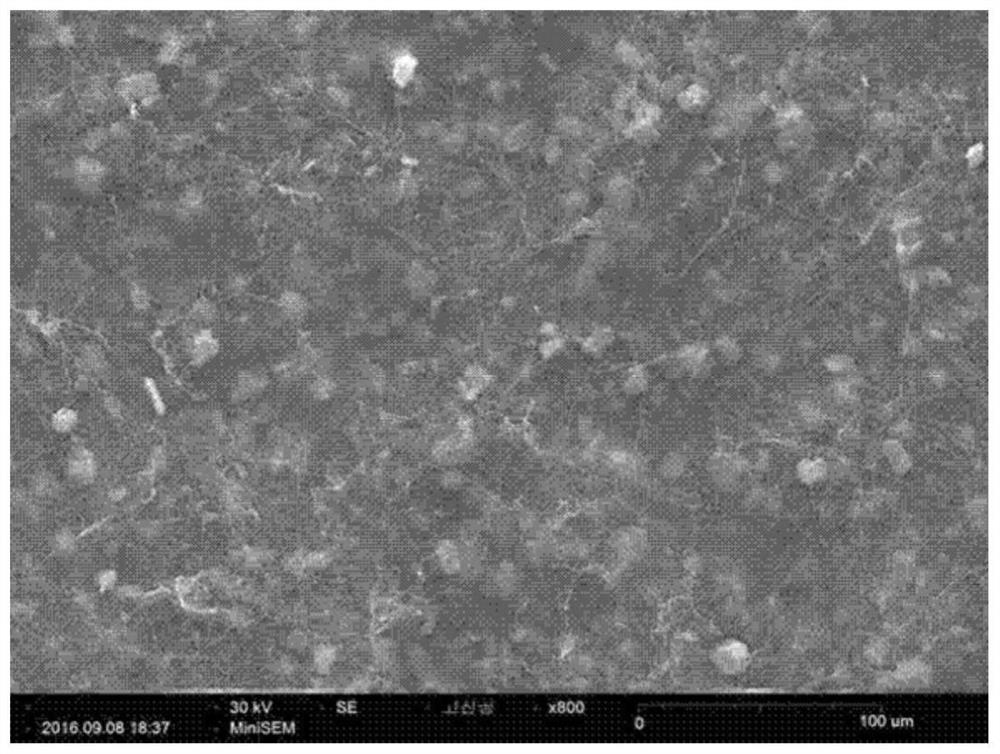

[0089] Preparation was carried out in the same manner as in Example 1, but the mixed solution was used as a spinning solution without centrifuging, and fiber webs for gas sensors shown in Table 1 below were produced.

[0090] The basis weight of the manufactured fiber web is 30g / ㎡, the average diameter of the nanofibers is 250nm, the porosity is 65%, and the nanofibers include parts whose diameter is 1.5 times or more than the average diameter.

Embodiment 3

[0092] The preparation was carried out in the same manner as in Example 1, but the lead acetate trihydrate was dry-milled instead of preparing the dispersion, and the pulverized lead acetate trihydrate was mixed in the prepared fiber-forming component solution, so that the spinning solution similar to that of Example 1 was obtained. The same content was then mixed using a magnetic bar at 25° C. during 2 hours to prepare a spinning solution, which was used to manufacture fiber webs for gas sensors shown in Table 1 below.

[0093] The basis weight of the manufactured fiber web was 20 g / ㎡, the average diameter of the nanofibers was 400 nm, the porosity was 43%, and the nanofibers contained parts whose diameter was 1.5 times or more than the average diameter.

[0094]

[0095] Using the fiber-forming component solution of Example 1 as the spinning solution, spinning under the same conditions produced a PVDF fiber web with a basis weight of 28 g / ㎡, an average diameter of nanofiber...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| humidity | aaaaa | aaaaa |

| humidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com