Preparation method and application of high-content rhamnose syrup

A high-content rhamnose syrup technology, which is applied in the field of preparation of high-content rhamnose syrup, can solve the problems of many impurities, and achieve the effects of good storage, high peak flavor, and difficult crystallization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

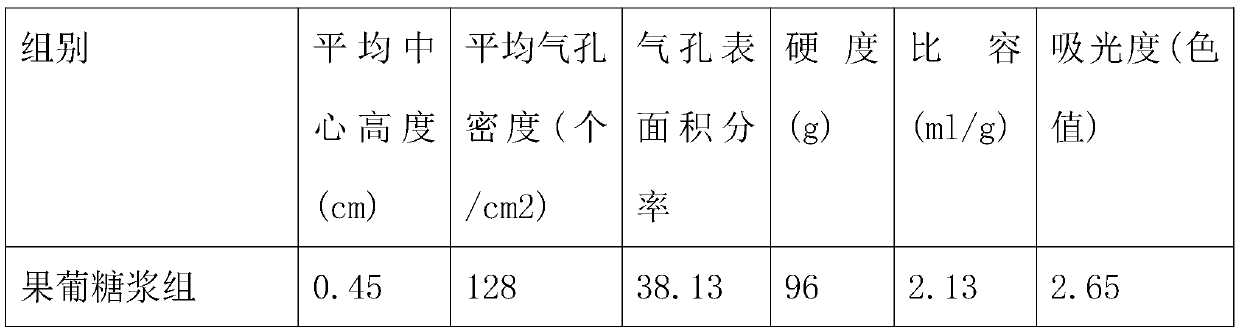

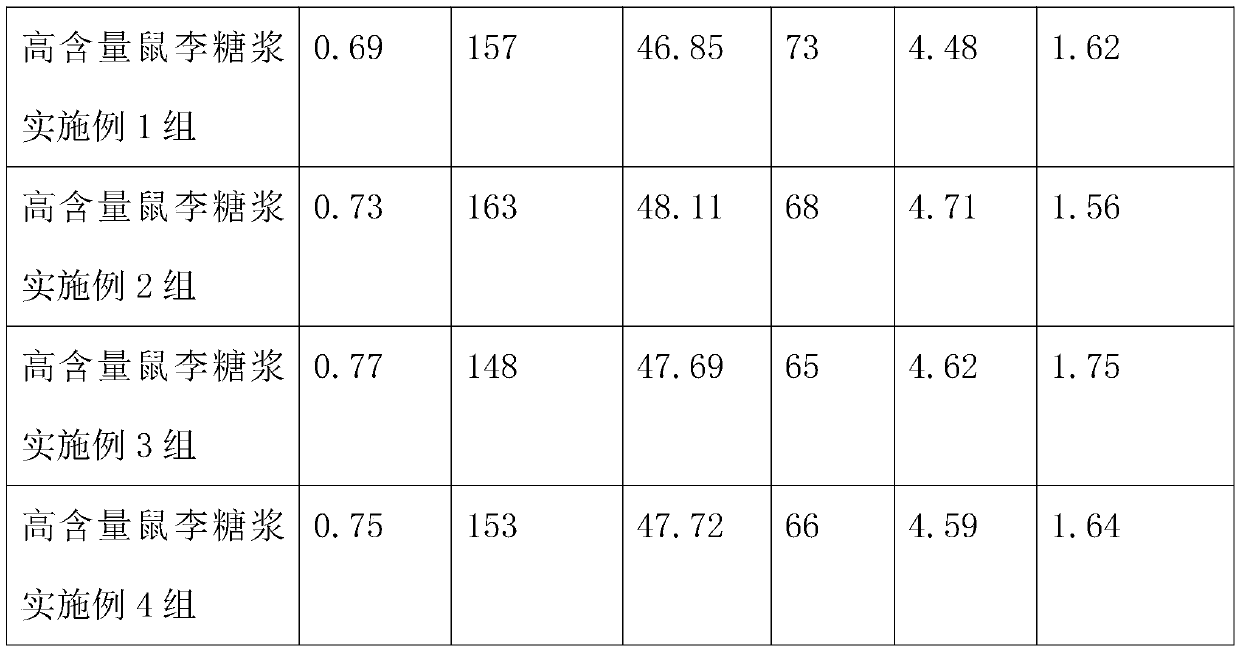

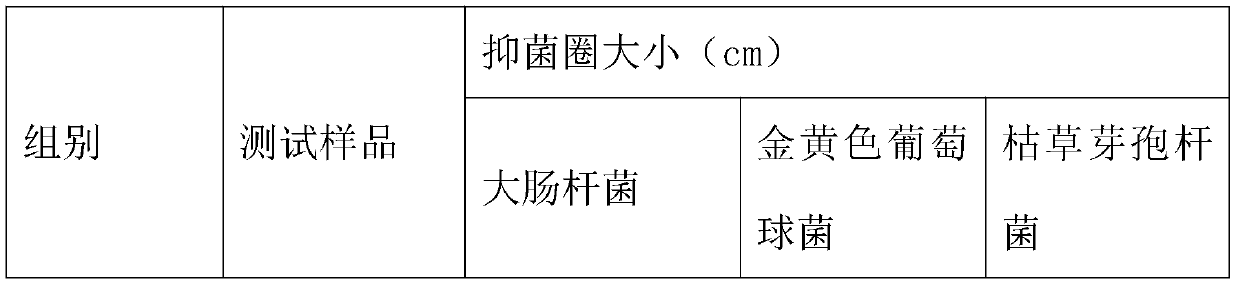

Examples

Embodiment 1

[0017] A preparation method for high-content rhamnose syrup, comprising the steps of:

[0018] S1: Take low-content rhamnose syrup (tested, water content 50%, rhamnose content 25%, xylose content 15%, arabinose content 8%), add rhamnose powder by weighing, fully stir and mix evenly, And preheated for 20 minutes at a temperature of 60° C., and compounded into a high-content rhamnose crude product (after testing, the water content was 37%, and the rhamnose accounted for 70% of the dry matter content);

[0019] S2: Send the crude product syrup to the floater, add 30PPM phosphoric acid and 0.1PPM sucrose compound additive (chitosan), and float at a low temperature of 65°C to remove ash, calcium salt, sulfate, colloidal substances, sugar acid flocculation thing;

[0020] S3: add pure water to the floating clear syrup and dilute it to a sugar concentration of 30%, perform electrodialysis desalination, operating voltage 35V, syrup flow rate 20L / h, to obtain a desalination solution (...

Embodiment 2

[0026] A preparation method for high-content rhamnose syrup, comprising the steps of:

[0027] S1: Take low-content rhamnose syrup (tested, water content 50%, rhamnose content 20%, xylose content 18%, glucose content 10%), add rhamnose powder by weighing, add appropriate amount of pure water and stir well Mix evenly, and preheat for 20 minutes at a temperature of 70°C, and compound into a crude product of high-content rhamnose syrup (after testing, the water content is 40%, and the rhamnose accounts for 75% of the dry matter content);

[0028] S2: Send the crude syrup to the floater, add 50PPM phosphoric acid and 1PPM sucrose compound additive (polyacrylamide), and float at a low temperature of 65°C to remove ash, calcium salt, sulfate, colloidal substances, and sugar-acid flocs ;

[0029] S3: adding pure water to the floating clear syrup and diluting it to a sugar concentration of 35%, performing electrodialysis desalination, operating voltage 40V, syrup flow rate 18L / h, to ...

Embodiment 3

[0035] A preparation method for high-content rhamnose syrup, comprising the steps of:

[0036] S1: Take low-content rhamnose syrup (tested, water content 50%, rhamnose content 25%, xylose content 15%, arabinose content 8%), add rhamnose powder by weighing, fully stir and mix evenly, and preheated for 20 minutes at a temperature of 80° C., and compounded into a high-content rhamnose crude product (after testing, the water content was 40%, and the rhamnose accounted for 80% of the dry matter content);

[0037] S2: Send the crude syrup to the floater, add 40PPM phosphoric acid and 0.5PPM sucrose compound additive (polyacrylamide), and float at a low temperature of 65°C to remove ash, calcium salt, sulfate, colloidal substances, sugar acid flocculation thing;

[0038] S3: adding pure water to the floating clear syrup and diluting it to a sugar concentration of 25%, performing electrodialysis desalination, operating voltage 30V, syrup flow rate 25L / h, to obtain a desalination solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com