Optical glass, glass perform thereof, optical element and optical instrument

A glass preform, optical glass technology, applied in optical components, optics, instruments, etc., can solve the problems of insignificant improvement effect and unsatisfactory optical crown glass hardness, and achieve high mechanical strength of glass, high resistance to punching, The effect of high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

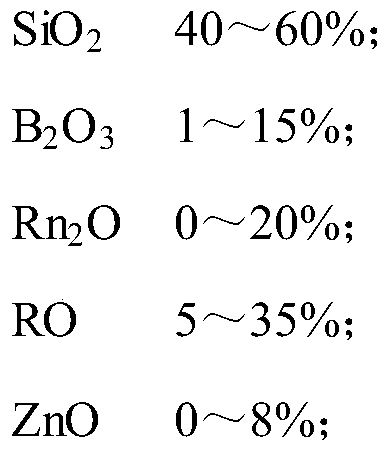

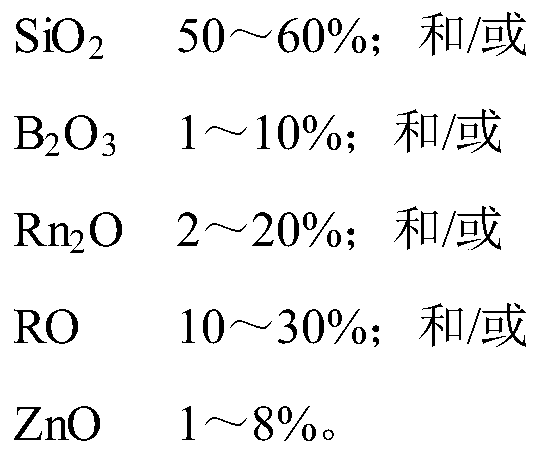

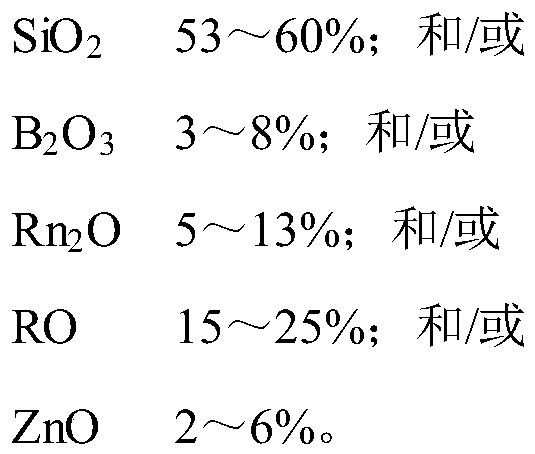

[0081] An optical glass, the composition and performance of which are shown in Table 2-Table 4 in terms of wt%.

[0082] Table 2

[0083]

[0084]

[0085] table 3

[0086]

[0087]

[0088] Table 4

[0089]

[0090]

[0091] The optical elements formed by the optical glass of the present invention can be used to make optical instruments such as photographic equipment, imaging equipment, display equipment and monitoring equipment. By using the above-mentioned optical element with excellent performance on the optical instrument, the customer experience of the optical instrument can be improved. It should be noted that the features and advantages described above for the optical element are also applicable to the optical instrument, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| transition temperature | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com