PP nano composite material and preparation method thereof

A nano-composite material and nano-material technology, applied in the field of PP nano-composite material and its preparation, can solve the problems of product performance impact, polyamide failure to enter the interlayer in time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

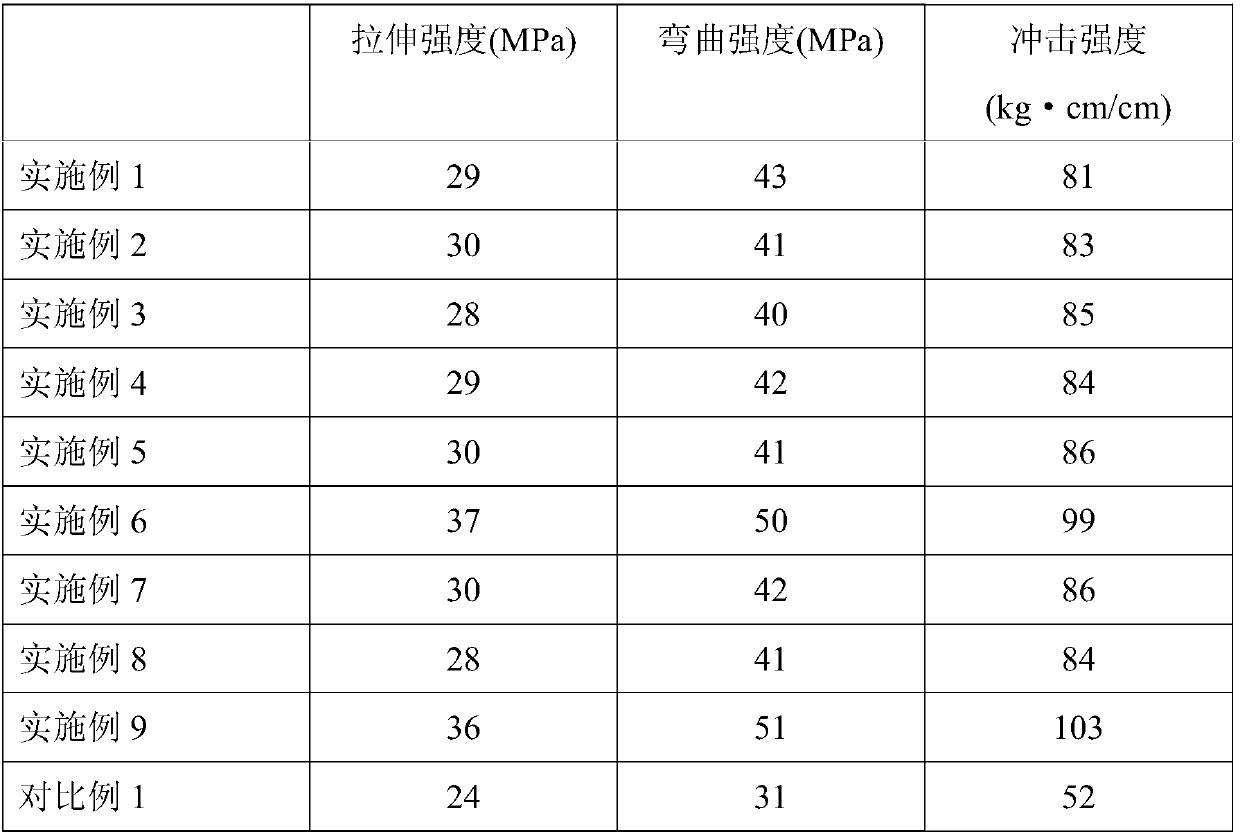

Examples

Embodiment 1

[0085] In this embodiment, the mass ratio of nanomaterials to polypropylene is 12:100, the liquid medium used is water, the auxiliary agent used is cetylpyridinium chloride, and the nanomaterials used are nano-alumina, according to the following method Preparation of nanocomposites:

[0086] (1) The liquid medium is stirred, and the nanomaterial is added at a speed of 4.5g / min to continuously stir and disperse evenly, and the weight ratio of the liquid medium to the nanomaterial is 20:1;

[0087] (2) Add additives to the continuous stirring solution of step (1) in batches or at a time at a speed of 0.1g / min to obtain a paste, the consistency of which is 34mm, the additives and nanomaterials The weight ratio is 10:1;

[0088] (3) the paste obtained in step (2) is mixed with polypropylene to obtain a premix;

[0089] (4) The premix of step (3) is fed into the screw extruder from the pressureless feed zone, melt blended and carried out subsequent processing to obtain nanocompos...

Embodiment 2

[0093] In this embodiment, the mass ratio of nanomaterials to polypropylene is 10:100, the liquid medium used is acetone and water, and the mass ratio of acetone to water is 7:93, and the auxiliary agents used are polyacrylic acid and polymarine To anhydride, the weight ratio is 1:1, the nanometer material that adopts is nanometer silicon, prepares nanocomposite material according to the following method:

[0094] (1) The liquid is stirred, and the nanomaterial is added at a speed of 10g / min to continuously stir and disperse evenly, and the weight ratio of the liquid medium to the nanomaterial is 100:1;

[0095] (2) Add auxiliary agent to the continuous stirring solution of step (1) with the speed of 0.5g / min, obtain paste, the consistency of described paste is 25mm, and the weight ratio of described auxiliary agent and nanometer material is 50:1;

[0096] (3) the paste obtained in step (2) is mixed with polypropylene to obtain a premix;

[0097] (4) The premix of step (3) i...

Embodiment 3

[0101] In this embodiment, the mass ratio of nanomaterials to polypropylene is 0.1:100, the liquid medium used is water, the auxiliary agent used is sodium alginate, the nanomaterials used are nano-zirconia and nano-silicon carbide, and the mass ratio is 8:2, prepare nanocomposites according to the following method:

[0102] (1) The liquid medium is stirred, and the nanomaterial is added at a speed of 0.01g / min to continuously stir and disperse evenly, and the weight ratio of the liquid medium to the nanomaterial is 50:1;

[0103] (2) Add auxiliary agent to the continuous stirring solution of step (1) at a speed of 10g / min to obtain a paste, the consistency of the paste is 38mm, and the weight ratio of the auxiliary agent to nanomaterial is 0.1 :1;

[0104] (3) the paste obtained in step (2) is mixed with polypropylene to obtain a premix;

[0105] (4) with the premix internal mixer of step (3), melt blending and carry out follow-up processing, obtain nanocomposite material. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| flow consistency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com