A Soil Efficient Restoration Material

A repairing material and high-efficiency technology, which can be used in soil conditioning materials, restoration of polluted soil, organic fertilizers, etc. It can solve the problems of low fixation rate of heavy metals, achieve long curing time, low cost, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

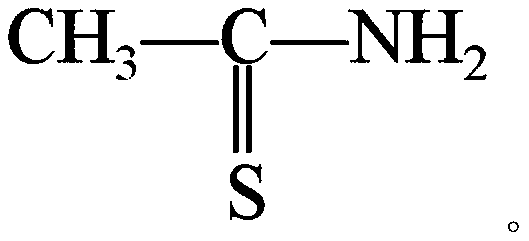

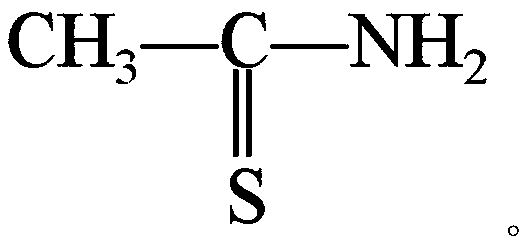

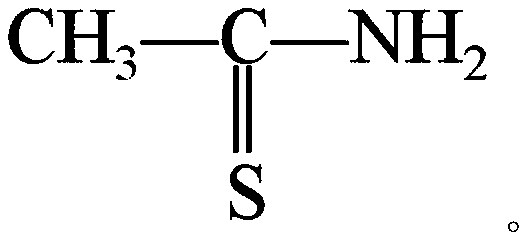

Image

Examples

Embodiment 1

[0033] An efficient soil repair material, the repair material is composed of straw glue, bentonite, slaked lime, polyacrylamide, potassium methyl silicate, and gypsum powder, and the straw glue is made from natural straw fibers through aging, gelatinization and grinding. Concrete preparation steps are as follows:

[0034] (1) Mix the natural straw fiber and the straw decomposing agent evenly according to a certain weight part, stack them into stacks, place them in the open air for fermentation and aging, and then add modified silica gel, sodium chloride and chloride to the mature straw fibers. Calcium, heated and pressurized in a flat vulcanizer to gelatinize the straw fiber, then dried and crushed to obtain powdery straw glue; wherein, 67 parts by weight of natural straw fiber, 2 parts by weight of straw decomposing agent, 20 parts by weight of modified silica gel, 1 part by weight of sodium chloride, and 1 part by weight of calcium chloride;

[0035] (2) Mix the straw glue ...

Embodiment 2

[0052] An efficient soil repair material, the repair material is composed of straw glue, bentonite, slaked lime, polyacrylamide, potassium methyl silicate, and gypsum powder, and the straw glue is made from natural straw fibers through aging, gelatinization and grinding. Concrete preparation steps are as follows:

[0053] (1) Mix the natural straw fiber and the straw decomposing agent evenly according to a certain weight part, stack them into stacks, place them in the open air for fermentation and aging, and then add modified silica gel, sodium chloride and chloride to the mature straw fibers. Calcium, heat and pressurize in a flat vulcanizer to gelatinize the straw fiber, then dry and pulverize to obtain powdery straw glue; wherein, 72 parts by weight of natural straw fiber, 3 parts by weight of straw decomposing agent, 22.5 parts by weight of modified silica gel, 1.5 parts by weight of sodium chloride, and 1.5 parts by weight of calcium chloride;

[0054] (2) Mix the straw ...

Embodiment 3

[0071] An efficient soil repair material, the repair material is composed of straw glue, bentonite, slaked lime, polyacrylamide, potassium methyl silicate, and gypsum powder, and the straw glue is made from natural straw fibers through aging, gelatinization and grinding. Concrete preparation steps are as follows:

[0072] (1) Mix the natural straw fiber and the straw decomposing agent evenly according to a certain weight part, stack them into stacks, place them in the open air for fermentation and aging, and then add modified silica gel, sodium chloride and chloride to the mature straw fibers. Calcium, heated and pressurized in a flat vulcanizer to gelatinize straw fibers, then dried and crushed to obtain powdered straw glue; wherein, 76 parts by weight of natural straw fibers, 4 parts by weight of straw decomposing agent, 25 parts by weight of modified silica gel, 2 parts by weight of sodium chloride, and 2 parts by weight of calcium chloride;

[0073] (2) Mix the straw glue...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com