Preparation method of solvent-type nanofiber

A nanofiber and solvent technology, applied in spinning solution preparation, fiber processing, fiber chemical characteristics, etc., can solve the problems affecting the quality of the finished product, the static bending strength and internal bonding strength of nanofibers, and no preparation method. Equipment and working environment specifications and other problems to achieve the effect of improving the quality of finished products, good static bending strength and internal bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

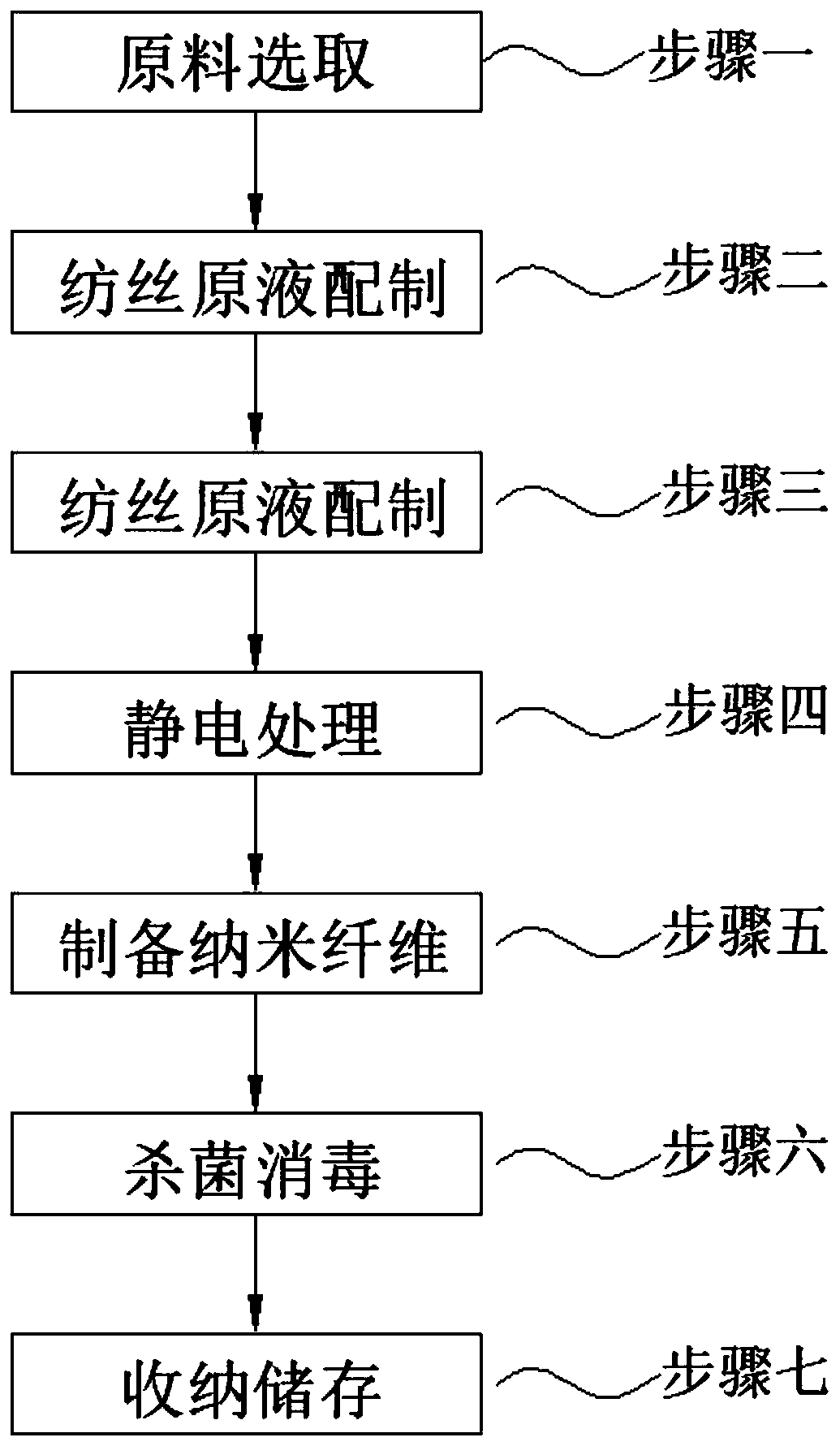

[0023] A solvent-type nanofiber preparation method, comprising the following steps: Step 1, raw material selection; Step 2, spinning stock solution preparation; Step 3, ultrasonic vibration treatment; Step 4, electrostatic treatment; Step 5, preparing nanofibers; Step 6, Sterilization; step seven, storage;

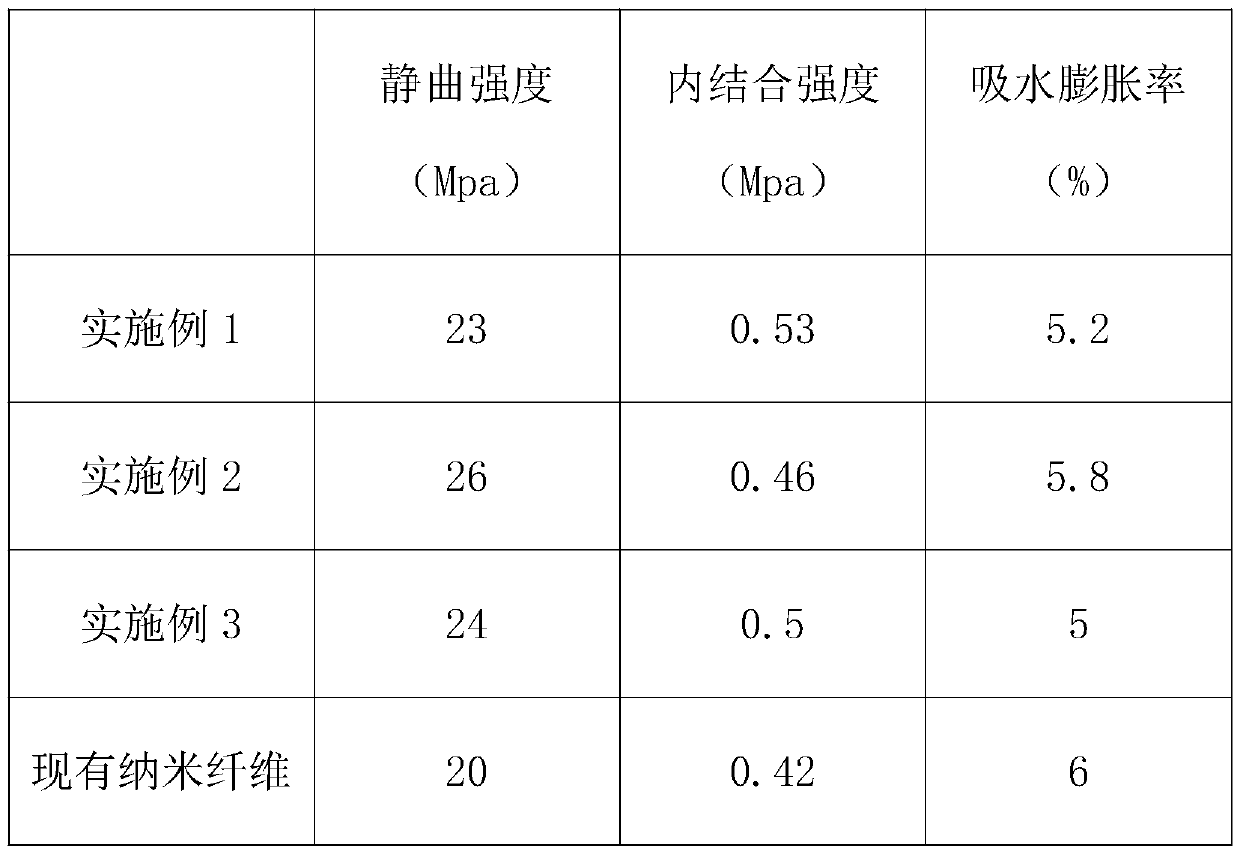

[0024] Wherein in the above-mentioned step 1, according to the mass percentage content of each component, ethyl methacrylate 15%, isoamyl acrylic acid 15%, β-butyl itaconate 5%, 2-butenoic acid 15% , 3% of methyl maleic acid, 11% of acrylonitrile, 36% of dimethyl sulfoxide, and weighed according to the sum of the weight percentages being 1;

[0025] Wherein in above-mentioned step 2, ethyl methacrylate, isopropyl acrylic acid, β-butyl itaconate, dimethyl sulfoxide weighed in step 1 are added respectively in the reactor and reacted, and the reaction time is 1~3h, the reaction temperature is 100~120°C; then add 2-butenoic acid and methyl maleic acid in sequence for mixing a...

Embodiment 2

[0038] A solvent-type nanofiber preparation method, comprising the following steps: Step 1, raw material selection; Step 2, spinning stock solution preparation; Step 3, ultrasonic vibration treatment; Step 4, electrostatic treatment; Step 5, preparing nanofibers; Step 6, Sterilization; step seven, storage;

[0039] Wherein in the above-mentioned step 1, according to the mass percentage content of each component, ethyl methacrylate 20%, isoamyl acrylic acid 15%, β-butyl itaconate 5%, 2-butenoic acid 15% , methyl maleic acid 3%, acrylonitrile 11%, dimethyl sulfoxide 31%, and weighed according to the sum of the weight percentages being 1;

[0040] Wherein in above-mentioned step 2, ethyl methacrylate, isopropyl acrylic acid, β-butyl itaconate, dimethyl sulfoxide weighed in step 1 are added respectively in the reactor and reacted, and the reaction time is 1~3h, the reaction temperature is 100~120°C; then add 2-butenoic acid and methyl maleic acid in sequence for mixing and stirri...

Embodiment 3

[0053] A solvent-type nanofiber preparation method, comprising the following steps: Step 1, raw material selection; Step 2, spinning stock solution preparation; Step 3, ultrasonic vibration treatment; Step 4, electrostatic treatment; Step 5, preparing nanofibers; Step 6, Sterilization; step seven, storage;

[0054] Wherein in above-mentioned step 1, according to the mass percent content of each component, ethyl methacrylate 26%, isoamyl acrylic acid 15%, β-butyl itaconate 5%, 2-butenoic acid 15% , 3% methyl maleic acid, 11% acrylonitrile, 25% dimethyl sulfoxide, and weighed according to the sum of the percentages by weight being 1;

[0055] Wherein in above-mentioned step 2, ethyl methacrylate, isopropyl acrylic acid, β-butyl itaconate, dimethyl sulfoxide weighed in step 1 are added respectively in the reactor and reacted, and the reaction time is 1~3h, the reaction temperature is 100~120°C; then add 2-butenoic acid and methyl maleic acid in sequence for mixing and stirring, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com