Acidic ammonium salt vanadium precipitation waste water comprehensive utilization method

A technology for precipitation of vanadium with acid ammonium salt and waste water, applied in the field of vanadium metallurgy, can solve the problems of loss and waste of vanadium and excess alkali, long technical process, difficult industrial implementation, etc., and achieves reduction of waste of new water, simple operation, and easy industrialization. applied effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

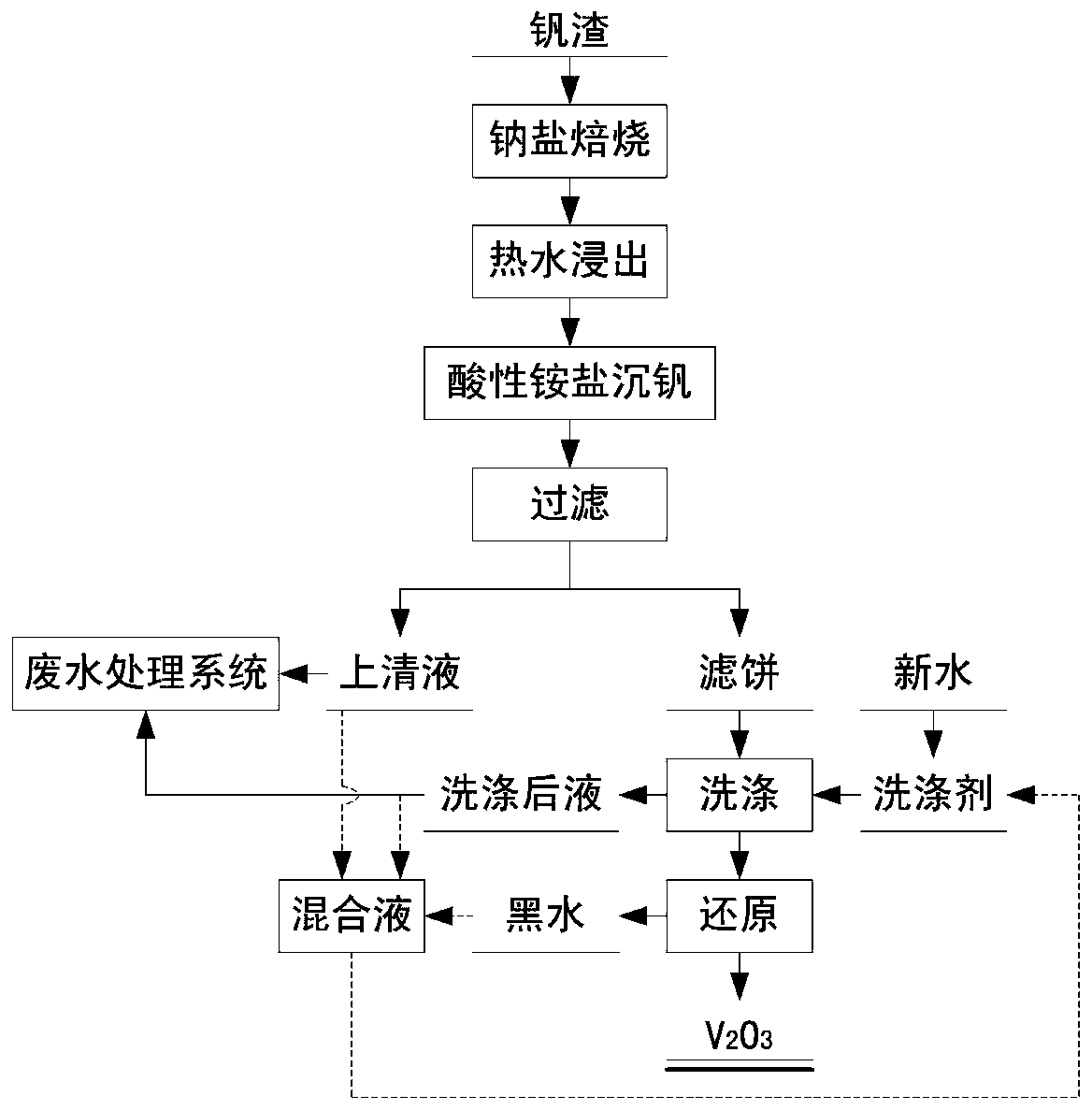

Method used

Image

Examples

Embodiment 1

[0042] Take 230g of APV filter cake with a moisture content of 35%, put it into a Buchner funnel; take 1mL solution A (TV content is 0.25g / L), 99mL solution B (TV content is 0.03g / L), 50mL solution C (TV content is 0.21g / L), after mixing evenly, heat up to 55°C to obtain APV detergent, the pH of the detergent is 4.61; take 50mL of detergent for washing each time, soak for 30s, and wash 3 times in total. After washing, the TV in the APV product is 49.86%, Na 2 O is 0.31%, K 2 O is 0.13%, S is 0.14%, and the product quality meets the requirements. The liquid volume after washing is 146mL, and the TV content is 0.08g / L, then the recovery rate of vanadium in the detergent is 85.51%.

Embodiment 2

[0044] Take 221g of APV filter cake with a water content of 32%, put it into a Buchner funnel; take 1mL solution A (TV content is 0.29g / L), 66mL solution B (TV content is 0.03g / L), 33mL solution C (TV content is 0.34g / L), mix evenly, and heat up to 65°C to obtain APV detergent. After washing, the TV in the APV product is 49.71%, Na 2 O is 0.38%, K 2 O is 0.13%, S is 0.14%, and the product quality meets the requirements. The liquid volume after washing is 95mL, and the TV content is 0.08g / L, then the recovery rate of vanadium in the detergent is 86.59%.

Embodiment 3

[0046] Take 227g of APV filter cake with a moisture content of 34%, put it into a Buchner funnel; take 1mL solution A (TV content is 0.22g / L), 168mL solution B (TV content is 0.04g / L), 101mL solution C (TV content is 0.35g / L), mix evenly, and heat up to 70°C to obtain APV detergent, the pH of which is 6.86; take 90mL of detergent for washing each time, soak for 30s, and wash 3 times in total. After washing, the TV in the APV product is 50.06%, Na 2 O is 0.35%, K 2 O is 0.13%, S is 0.13%, and the product quality meets the requirements. The liquid volume after washing is 261mL, and the TV content is 0.14g / L, then the recovery rate of vanadium in the detergent is 86.53%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com