Composite material of polyether block amide monomer foamed particles and polyurethane and preparation method and application of composite material of polyether block amide monomer foamed particles and polyurethane

A technology of foamed particles and polyether amide, which is applied in the field of composite materials of block polyether amide elastomer foamed particles and polyurethane and its preparation, can solve the problems of low yield, high price, single appearance of products, etc., and achieve Effects of high compression deformation resistance, high bending fatigue resistance, and excellent tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) The block polyether amide elastomer foamed particles of 100g, the NCO content of 60g are the one-component polyurethane reactive hot-melt adhesive of 10%, the water of 6g, the dibutyltin dilaurate of 0.2g mix Evenly put into the mold, the density of the block polyether amide elastomer foamed particles is 0.175g / cm 3 , the shape is ellipsoid, the major diameter length is 4mm;

[0034] (2) Close the mold, pressurize and cure, the curing temperature is 70°C, the curing time is 6 minutes, and the pressurized pressure is 1MPa;

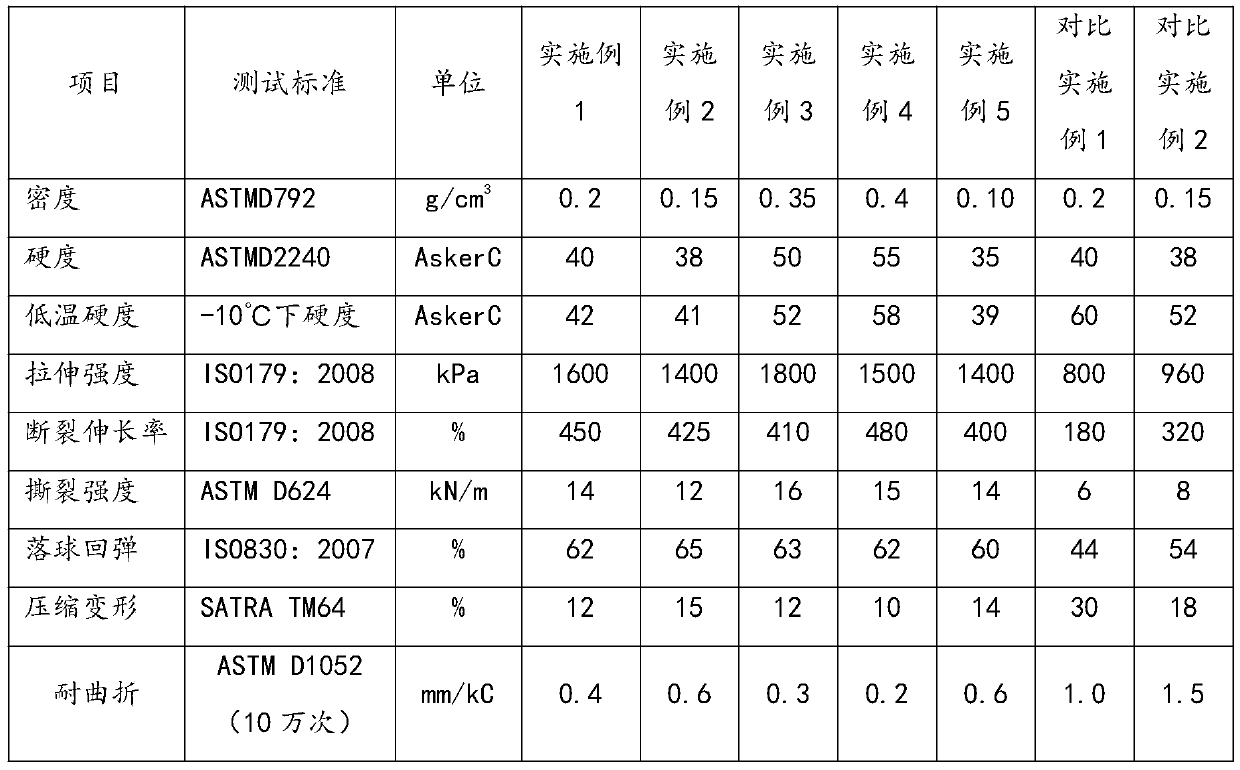

[0035] (3) Cool the mold temperature to 30° C., open the mold, and obtain a composite material of block polyetheramide elastomer foamed particles and polyurethane. The performance test data of the prepared composite material are shown in Table 1 below.

Embodiment 2

[0037] (1) The block polyether amide elastomer foamed particles of 100g, the NCO content of 200g are the one-component polyurethane reactive hot-melt adhesive of 20%, the water of 12g, the stannous dilaurate diacetic acid of 0.5g Dibutyltin is mixed evenly and put into the mold, in which the density of the block polyether amide elastomer foamed particles is 0.1g / cm 3 , the shape is spherical, the major diameter length is 8mm;

[0038] (2) Close the mold, pressurize and cure, the curing temperature is 100°C, the curing time is 4 minutes, and the pressurized pressure is 0.5MPa;

[0039] (3) Cool the mold temperature to 20°C and open the mold to obtain a composite material of block polyetheramide elastomer foamed particles and polyurethane. The performance test data of the prepared composite material are shown in Table 1 below.

Embodiment 3

[0041](1) Put 100g of block polyetheramide elastomer foamed particles, 30g of one-component polyurethane reactive hot melt adhesive with an NCO content of 1%, 1g of water, and 1g of triethylamine into the mold , wherein the density of block polyetheramide elastomer foamed particles is 0.5g / cm 3 , the shape is cylindrical, the major diameter length is 20mm;

[0042] (2) Close the mold, pressurize and cure, the curing temperature is 50°C, the curing time is 16 minutes, and the pressurized pressure is 5MPa;

[0043] (3) Cool the mold temperature to 30°C and open the mold to obtain a composite material of block polyetheramide elastomer foamed particles and polyurethane. The performance test data of the prepared composite material are shown in Table 1 below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com