Terahertz material used for emission reducing and oil saving of gasoline vehicle and preparing method and application thereof

A terahertz material and terahertz technology, applied in the terahertz field, can solve problems such as reducing exhaust hydrocarbons, and achieve the effects of improving energy conversion rate, improving power, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

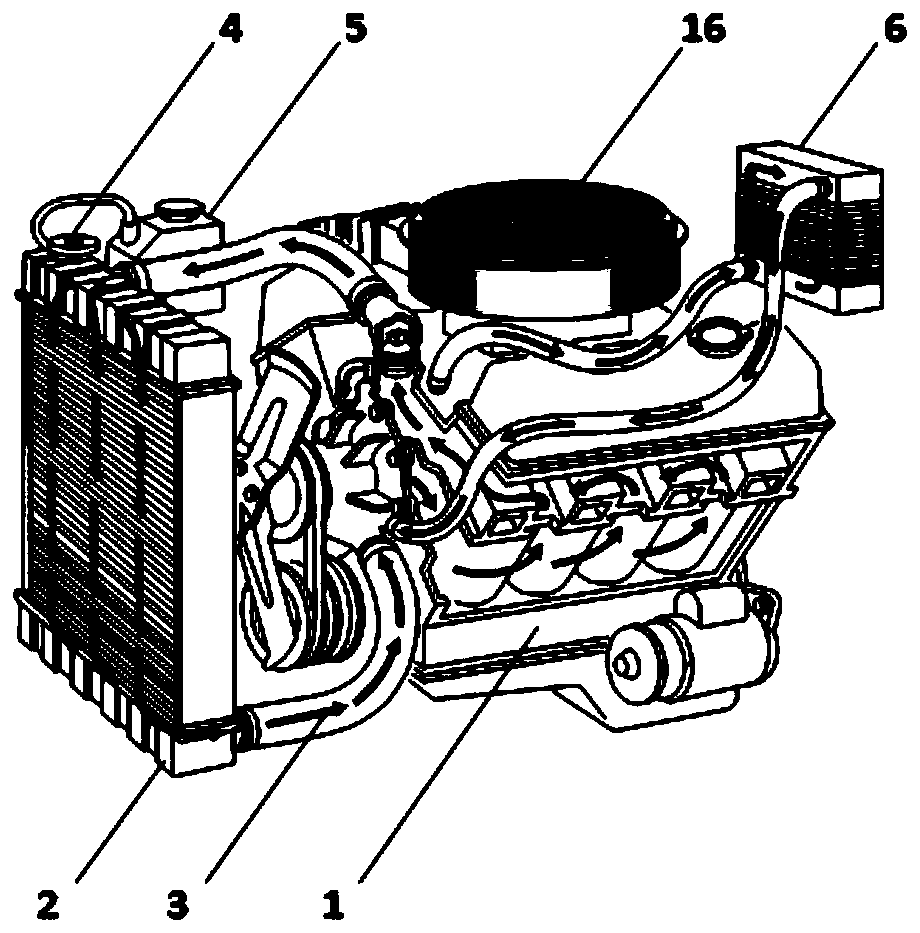

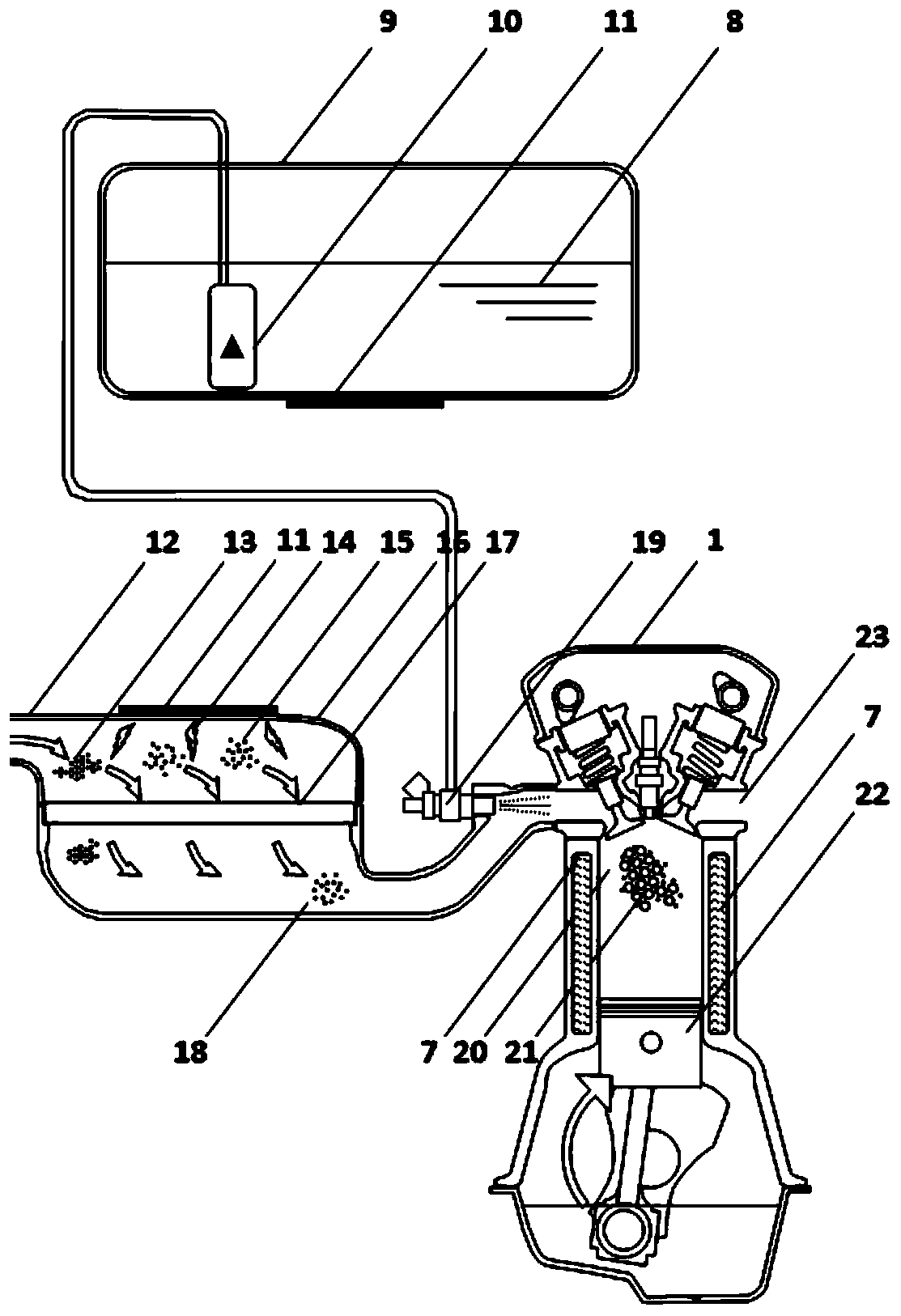

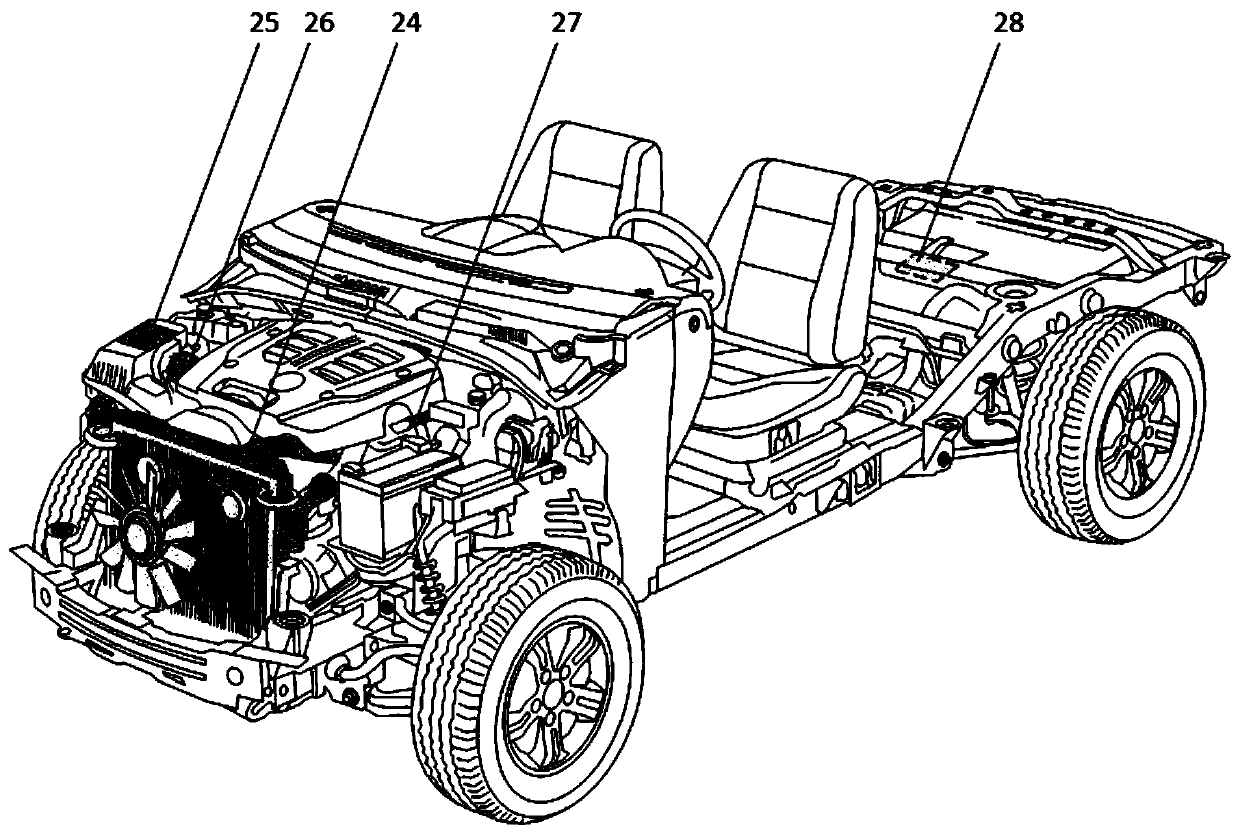

Method used

Image

Examples

Embodiment 1

[0034] A terahertz material used for emission reduction and fuel saving of gasoline vehicles, comprising the following raw materials in parts by weight: SiOx: 25, Al 2 o 3 : 8, SiO 2 : 30, Fe 2 o 3 : 20, ocher: 30, barium tungstate: 1, CaCO 3 :20.

[0035] The preparation method of the terahertz material used for emission reduction and fuel saving of gasoline vehicles comprises the following steps:

[0036] (1) The crude silicon Si, SiO 2 Mix it with Bincho charcoal according to the weight ratio of 1:4:8, heat it to 1200°C in an oxygen-free environment, and keep it for 5 hours to form black crystal SiOx;

[0037] (2) Mix the prepared SiOx with other raw materials according to the stated proportions, and after crushing, the fineness will reach 200-500 mesh. After adding an appropriate amount of water, stir, turn into small balls through a circular turntable, and enter an anaerobic environment Heating to 800°C, maintaining for 5 hours, and performing secondary crushing; ...

Embodiment 2

[0043] A terahertz material used for emission reduction and fuel saving of gasoline vehicles, comprising the following raw materials in parts by weight: SiOx: 20, Al 2 o 3 : 15, SiO 2 : 25, Fe 2 o 3 : 25, ocher: 20, barium tungstate: 2, CaCO 3 :15.

[0044] The preparation method of the terahertz material used for emission reduction and fuel saving of gasoline vehicles comprises the following steps:

[0045] Crude silicon Si, SiO 2 Mix it with Bincho charcoal according to the weight ratio of 1:3:5, heat it to 700°C in an oxygen-free environment, and keep it for 8 hours to form black crystal SiOx. Mixing in the above ratio, after crushing, the fineness reaches 200~500 mesh, add appropriate amount of water, stir, turn into small balls through a circular turntable, enter an anaerobic environment and heat to 1000°C, keep for 4 hours, and carry out secondary crushing; The emissivity is ≥0.92, and then crushed and powder processed again, the fineness reaches more than 10,000 ...

Embodiment 3

[0048] A terahertz material used for emission reduction and fuel saving of gasoline vehicles, comprising the following raw materials in parts by weight: SiOx: 35, Al 2 o 3 : 3, SiO 2 : 45, Fe 2 o 3 : 5, ocher: 40, barium tungstate: 0.5, CaCO 3 :25.

[0049] The preparation method of the terahertz material used for emission reduction and fuel saving of gasoline vehicles comprises the following steps:

[0050] (1) The crude silicon Si, SiO 2 Mix with Binchotan according to the weight ratio of 1: 5: 10, heat to 1500°C in an oxygen-free environment, and maintain it for 1 hour to form black crystal SiOx;

[0051] (2) Mix the prepared SiOx with other raw materials according to the stated proportions, and after crushing, the fineness will reach 200-500 mesh. After adding an appropriate amount of water, stir, turn into small balls through a circular turntable, and enter an anaerobic environment Heating to 600°C, maintaining for 8 hours, and performing secondary crushing;

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| emissivity | aaaaa | aaaaa |

| emissivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com