Coal-fired flue gas treatment composition, coal-fired flue gas treatment method, coal-fired flue gas treatment apparatus, and applications of composition, method and apparatus

A technology for treating composition and coal-burning flue gas, which is applied in the direction of gas treatment, separation methods, chemical instruments and methods, etc., can solve the problems such as unsatisfactory purification effect, achieve good resolution and elimination effect, and improve the degradation level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

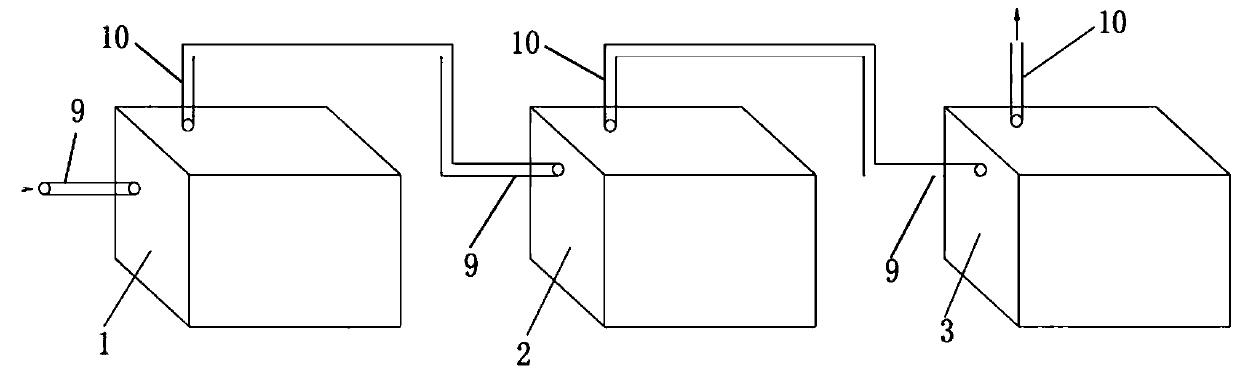

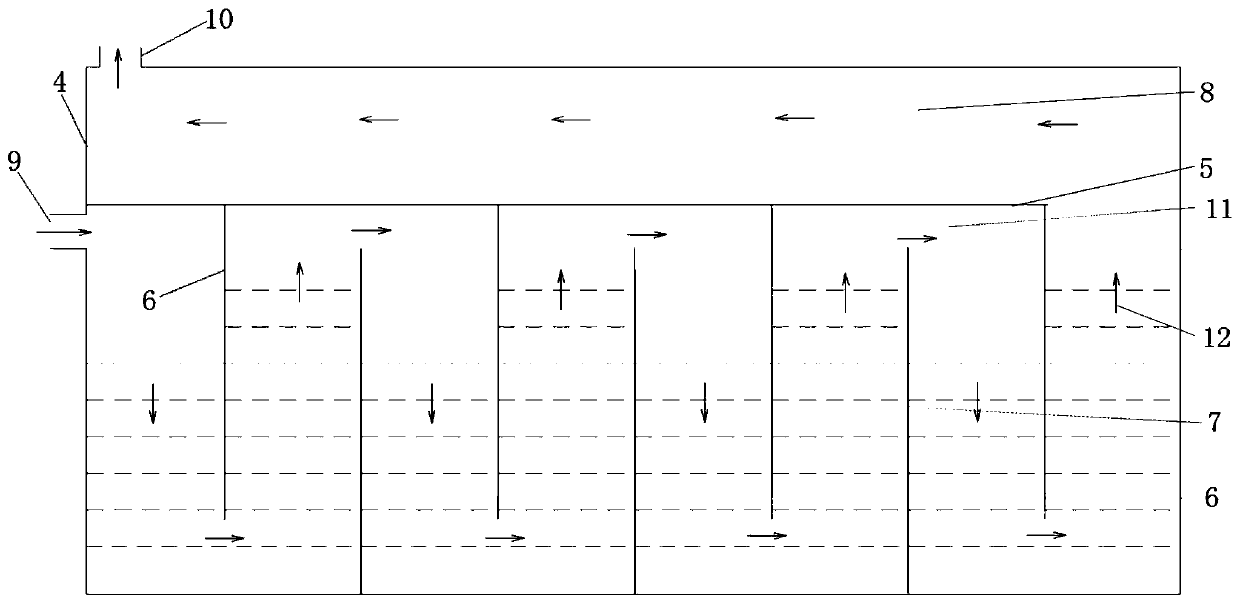

Method used

Image

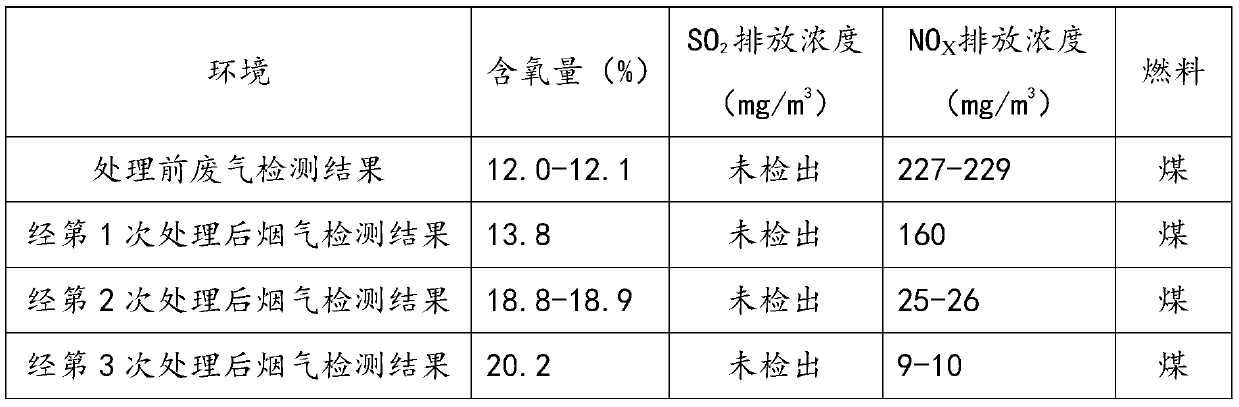

Examples

Embodiment 1

[0039] A coal-fired flue gas treatment composition, comprising: dicarbonic acid solution, nitrogen copper solution, sodium chloride solution used respectively; said dicarbonic acid solution is made up of sodium bicarbonate, sodium carbonate and solvent; said nitrogen copper solution is made up of It consists of a mother liquor and a seed liquor, wherein the mother liquor is prepared from heat-treated copper and urea solution, and the seed liquor is a urea solution. In the dicarbonic acid solution, the solvent is water. The mass ratio of described sodium bicarbonate, sodium carbonate and solvent is 3:100:1000. In the mother liquor, the heating temperature of copper is 200°C. In the mother liquor, the mass ratio of the heat-treated copper to the urea solution is 1:50; wherein, the mass percentage of the urea solution is 17%. In the seed liquid, the mass percentage of urea solution is 15%; in the sodium chloride solution, the mass ratio of sodium chloride to water is 1:50.

Embodiment 2

[0041] A coal-fired flue gas treatment composition, comprising: dicarbonic acid solution, nitrogen copper solution, sodium chloride solution used respectively; said dicarbonic acid solution is made up of sodium bicarbonate, sodium carbonate and solvent; said nitrogen copper solution is made up of It consists of a mother liquor and a seed liquor, wherein the mother liquor is prepared from heat-treated copper and urea solution, and the seed liquor is a urea solution. In the dicarbonic acid solution, the solvent is water. The mass ratio of described sodium bicarbonate, sodium carbonate and solvent is 1:75:800. In the mother liquor, the heating temperature of copper is 260°C. In the mother liquor, the mass ratio of the heat-treated copper to the urea solution is 1:40; wherein, the mass percentage of the urea solution is 20%. In the seed liquid, the mass percentage of urea solution is 11%; in the sodium chloride solution, the mass ratio of sodium chloride to water is 1:35.

Embodiment 3

[0043] A coal-fired flue gas treatment composition, comprising: dicarbonic acid solution, nitrogen copper solution, sodium chloride solution used respectively; said dicarbonic acid solution is made up of sodium bicarbonate, sodium carbonate and solvent; said nitrogen copper solution is made up of It consists of a mother liquor and a seed liquor, wherein the mother liquor is prepared from heat-treated copper and urea solution, and the seed liquor is a urea solution. In the dicarbonic acid solution, the solvent is water. The mass ratio of described sodium bicarbonate, sodium carbonate and solvent is 1:24:260. In the mother liquor, the heating temperature of copper is 180°C. In the mother liquor, the mass ratio of the heat-treated copper to the urea solution is 1:48; wherein, the mass percentage of the urea solution is 14%. In the seed liquid, the mass percentage of urea solution is 18%; in the sodium chloride solution, the mass ratio of sodium chloride to water is 1:70.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com