Black phosphorus-zinc indium sulfide composite visible-light photocatalyst and preparation method thereof

A catalyst and visible light technology, applied in physical/chemical process catalysts, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of inhibition, fast recombination of photogenerated carriers, low charge separation efficiency, etc., to achieve high hydrogen production, light The effect of high catalytic activity and easy operation of the synthesis method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

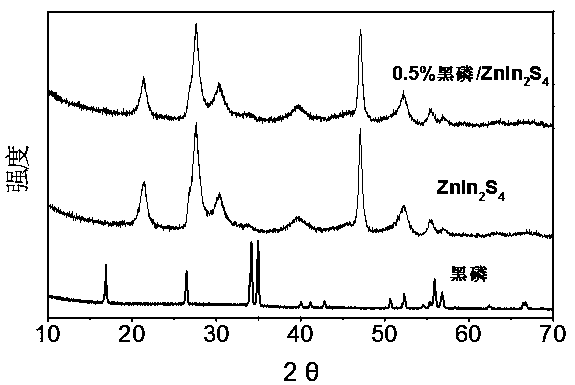

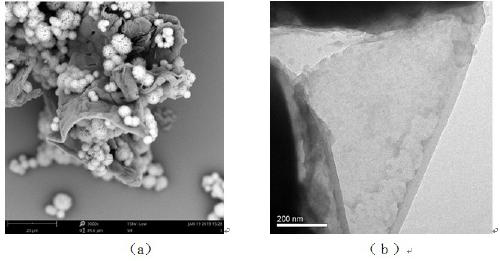

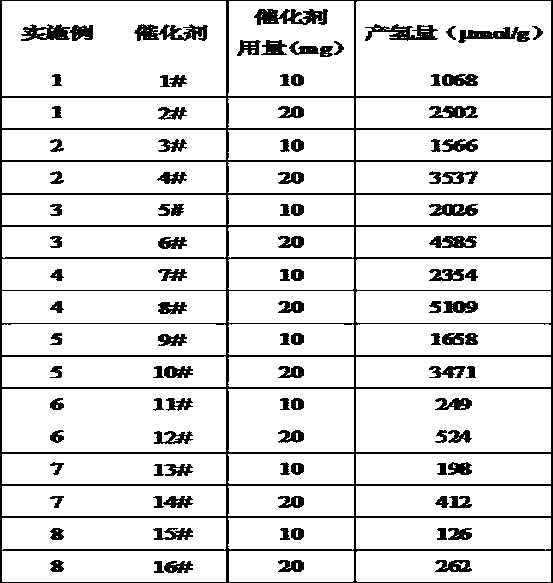

Embodiment 1

[0027] (1) Black phosphorus dispersion was prepared by ultrasonic exfoliation. The specific process was as follows: weigh 20 mg block black phosphorus crystals, grind them into powder in a mortar, mix them with 30 mL N-methylpyrrolidone into a 100 mL beaker, add 0.6 g NaOH stirred until dissolved. The beaker was placed in an ice-water bath at 10°C for ultrasonic peeling with a power of 180 W and a peeling time of 3 h. Centrifuge the stripping solution at 3000 rpm, take 2 / 3 of the supernatant, continue to centrifuge at 14000 rpm at high speed, wash the precipitate with distilled water for 3 times, and redisperse the obtained black solid in 20 mL of deionized water to obtain uniform black phosphorus Dispersion (0.2 mg / mL);

[0028] (2) Preparation of petal-shaped ZnIn by hydrothermal method 2 S 4 , the specific process is: weigh ZnCl according to the molar ratio of 1:2:4 2 , InCl 3 4H 2 O. Put thioacetamide (TAA) and 60 mL of distilled water in a 100 mL beaker, stir until ...

Embodiment 2

[0031] (1) The black phosphorus dispersion liquid prepared by ultrasonic stripping method is the same as that in Example 1;

[0032] (2) Preparation of petal-shaped ZnIn by hydrothermal method 2 S 4 With embodiment 1;

[0033] (3) Black phosphorus / ZnIn 2 S 4 The preparation of the composite catalyst, the specific process is: weighing ZnIn 2 S 4 Catalyst 100 mg, measure black phosphorus dispersion 0.25 mL, black phosphorus dispersion and ZnIn 2 S 4 The catalyst was mixed in 50 mL of closed aqueous solution, ultrasonically dispersed for 30 min, vacuumed and mechanically stirred continuously for 12 h, centrifuged at 14,000 rpm, and finally dried in vacuum at 60°C overnight to obtain 0.05% black phosphorus / ZnIn 2 S 4 Composite catalyst. Weigh different masses of 0.05% black phosphorus / ZnIn 2 S 4 composite catalyst (3 # : 10mg, 4 # : 20 mg), dispersed in 99.75 mL of water and added chloroplatinic acid (10 mg / mL, 28 uL) to conduct photolysis water hydrogen production te...

Embodiment 3

[0035] (1) The black phosphorus dispersion liquid prepared by ultrasonic stripping method is the same as that in Example 1;

[0036] (2) Preparation of petal-shaped ZnIn by hydrothermal method 2 S 4 With embodiment 1;

[0037] (3) Black phosphorus / ZnIn 2 S 4 The preparation of the composite catalyst, the specific process is: weighing ZnIn 2 S 4 Catalyst 100 mg, measure black phosphorus dispersion 1.25 mL, black phosphorus dispersion and ZnIn 2 S 4 The catalyst was mixed in 50 mL of closed aqueous solution, ultrasonically dispersed for 30 min, vacuumed and mechanically stirred continuously for 12 h, centrifuged at 14,000 rpm, and finally dried in vacuum at 60°C overnight to obtain 0.25% black phosphorus / ZnIn 2 S 4 Composite catalyst. Weigh different masses of 0.25% black phosphorus / ZnIn 2 S 4 composite catalyst (5 # : 10mg, 6 # : 20 mg), dispersed in 98.75 mL of water and added chloroplatinic acid (10 mg / mL, 28 uL) to carry out the hydrogen production test by photo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com