A Plasma Welding Process of Austenitic Stainless Steel 254SMO with Bypass Wire Feeding

A technology of austenitic stainless steel and plasma welding, applied in plasma welding equipment, welding equipment, welding equipment, etc., can solve problems such as difficult quality assurance, increased welding deformation, and large amount of welding materials, so as to improve efficiency and quality , reduce thermal deformation, good weld reinforcement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

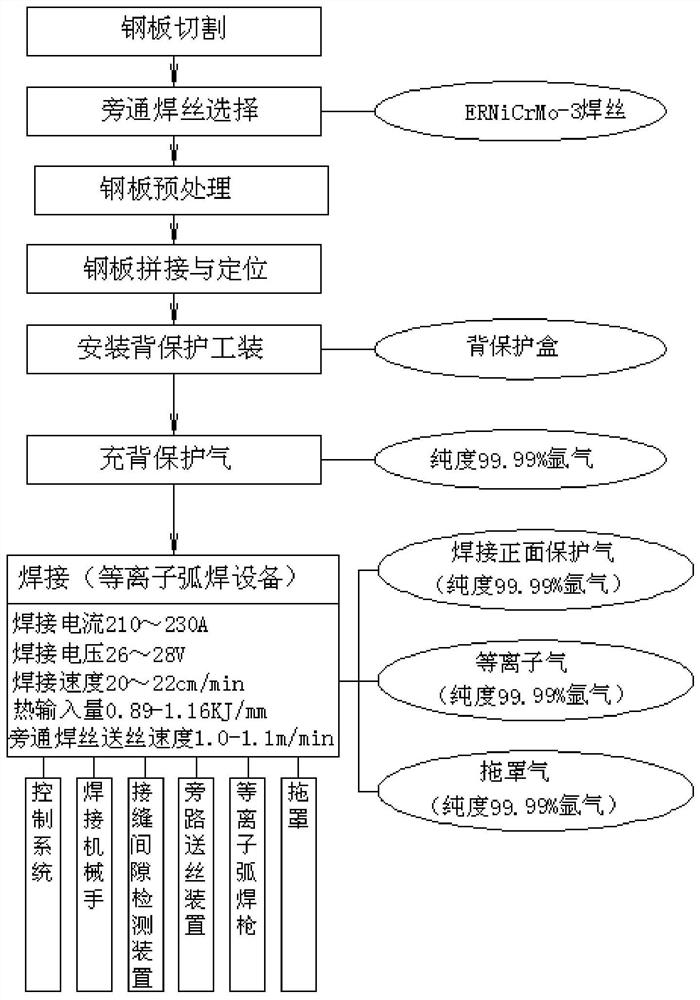

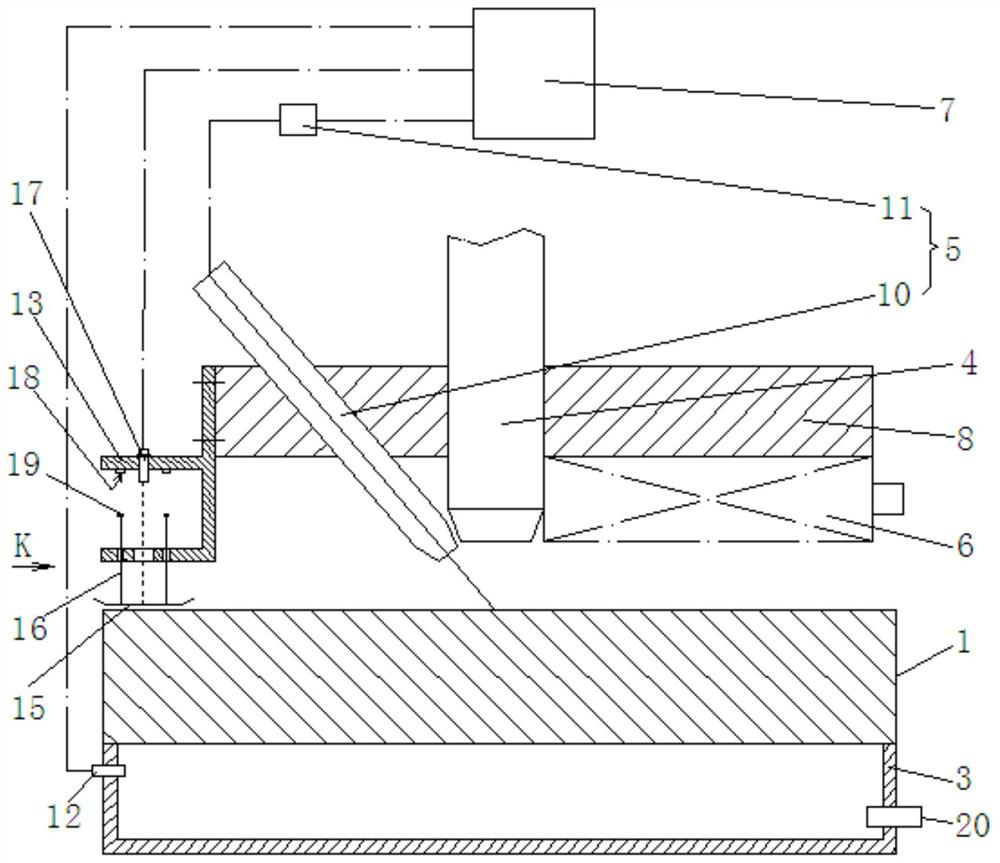

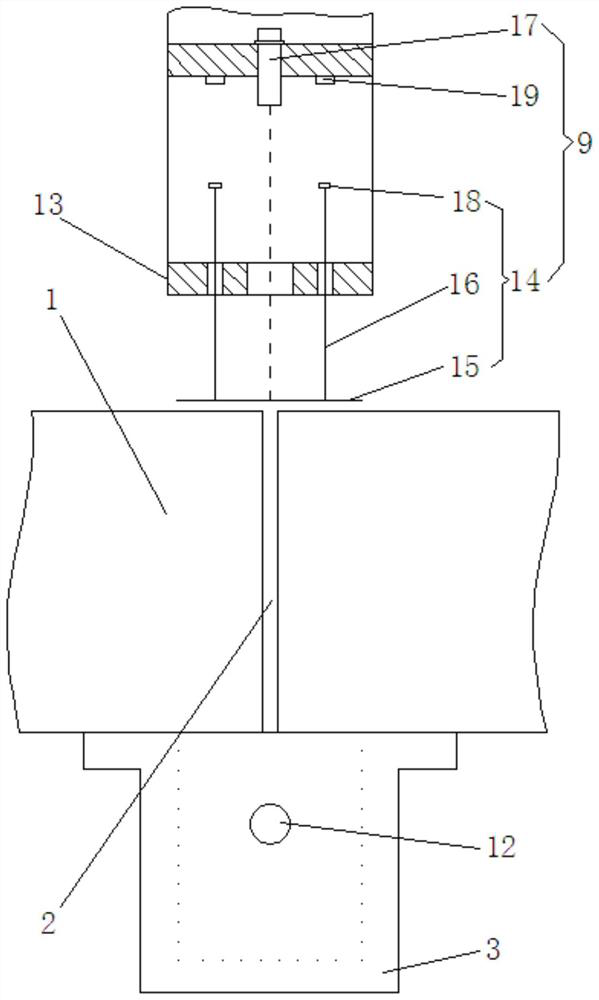

[0062] Such as Figures 1 to 5 Shown is the embodiment of the plasma welding process of a kind of austenitic stainless steel 254SMo with bypass wire feeding of the present invention, comprises following processing steps:

[0063] (1) Steel plate cutting: 254SMo stainless steel plate is used to cut and shape according to the design requirements;

[0064] (2) Selection of welding wire: use a welding wire with a diameter of φ1.2mm as the welding wire for bypass wire feeding during plasma arc welding;

[0065] (3) Steel plate pretreatment: perform surface pretreatment on the welding area of the stainless steel plate before welding;

[0066] (4) Steel plate splicing and positioning: the stainless steel plates to be welded are butted, and after the butt joint, the stainless steel plates are spot welded and positioned, and the position of the spot welded positioning is located at the butt seam on the back of the stainless steel plates;

[0067] (5) Install the back protection too...

Embodiment 2

[0101] Adopt the welding process of embodiment 1, carry out the test plate welding of austenitic stainless steel 254SMo, the welded test plate is processed according to the sample size requirement of corresponding detection standard, with American Bureau of Shipping (ABS) material and welding specification as guidance document, Check the following items, see the table below:

[0102]

[0103]

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com