Powder core welding wire for self-protecting electric-arc welding additive manufacturing of austenitic stainless steel

An austenitic stainless steel, additive manufacturing technology, applied in the direction of manufacturing tools, welding/cutting media/materials, welding media, etc., can solve the problem of inability to achieve fine grains of metal structure, achieve good toughness and plasticity, reduce Inclusion and grain refinement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

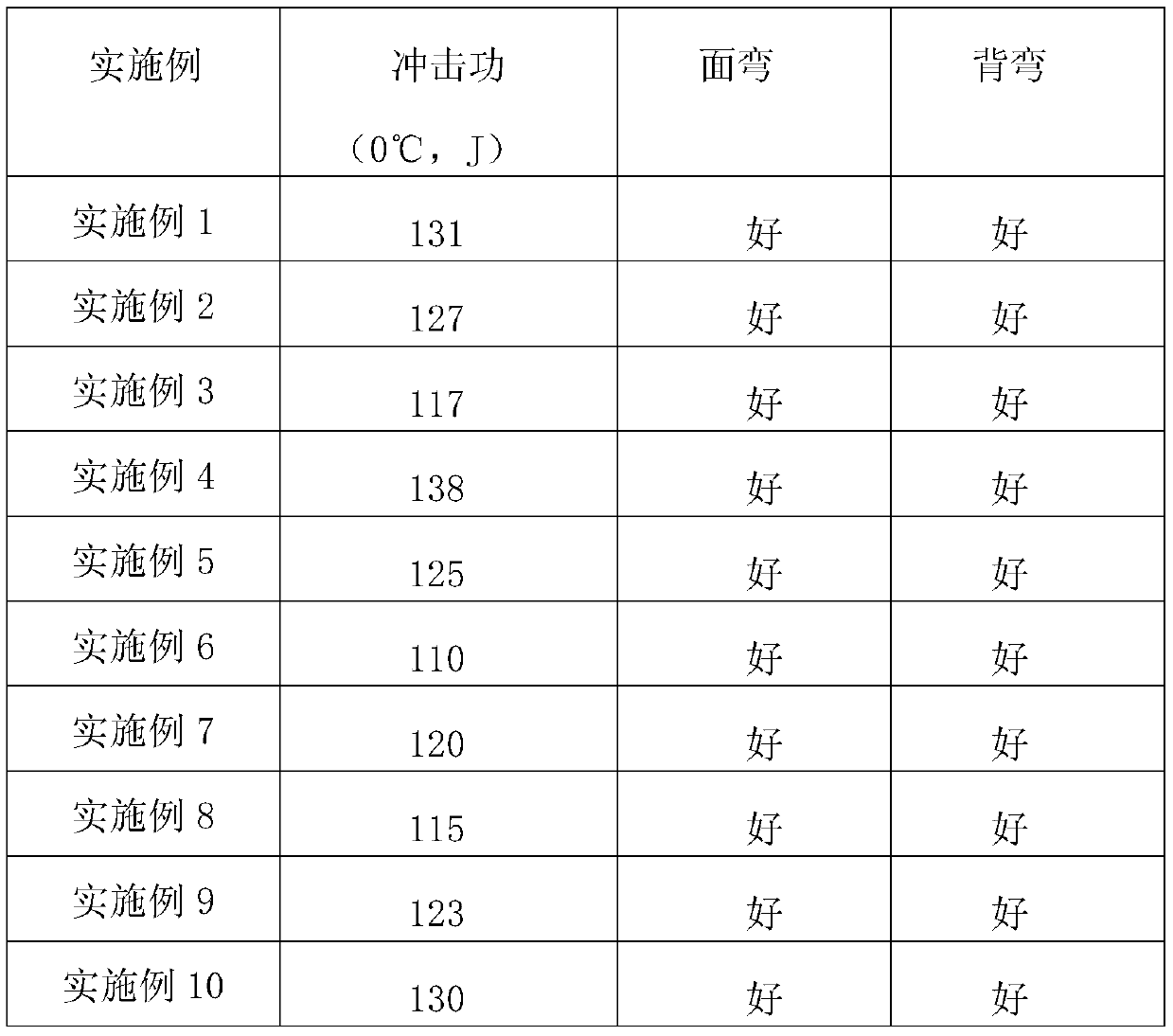

Examples

Embodiment 1

[0033] 1. Production of welding wire

[0034] The austenitic stainless steel self-shielded arc welding powder-cored welding wire for additive manufacturing in this embodiment includes a stainless steel sheath and a powder core, and the sheath and powder core contain the following components relative to the total mass fraction of the welding wire:

[0035] C:0.001%, Si:0.01%, Mn:6.0%, Cr:27.0%, Ni:1.0%, Mo:3.0%, Al:2%, Mg:2%, Ti:0.5%, LiBaF 3 : 5%, BaF 2 : 2%, rare earth oxide Ce 2 o 3 : 0.001%, LiFeO 2 : 1%, Zr: 0.1%, P: 0.03%, S: 0.01%, 0.25% of Ce and 0.25% of La.

[0036] Among the elements in the powder core, graphite is used for carbon, ferrosilicon is used for silicon, ferromanganese is used for manganese, metal chromium powder is used for chromium, metal nickel powder is used for nickel, metal molybdenum powder is used for molybdenum, aluminum powder is used for aluminum, and metal powder is used for magnesium. Magnesium powder, titanium metal titanium powder, zirc...

Embodiment 2

[0045] The austenitic stainless steel self-shielded arc welding powder-cored welding wire for additive manufacturing in this embodiment includes a stainless steel sheath and a powder core, and the sheath and powder core contain the following components relative to the total mass fraction of the welding wire:

[0046] C:0.1%, Si:0.05%, Mn:2.0%, Cr:17.0%, Ni:5.0%, Mo:1.0%, Al:3%, Mg:1%, Ti:0.001%, LiBaF 3 : 10%, BaF 2 : 5%, rare earth oxide Ce 2 o 3 : 0.35%, LiFeO 2 : 2%, Zr: 2%, P: 0.02%, S: 0.01%, 0.01% Ce and 0.5% La.

[0047] Among the elements in the powder core, graphite is used for carbon, ferrosilicon is used for silicon, ferromanganese is used for manganese, metal chromium powder is used for chromium, metal nickel powder is used for nickel, metal molybdenum powder is used for molybdenum, aluminum powder is used for aluminum, and metal powder is used for magnesium. Magnesium powder, titanium metal titanium powder, zirconium iron zirconium, Ce and La use La-Ce alloy p...

Embodiment 3

[0050] The austenitic stainless steel self-shielded arc welding powder-cored welding wire for additive manufacturing in this embodiment includes a stainless steel sheath and a powder core, and the sheath and powder core contain the following components relative to the total mass fraction of the welding wire:

[0051] C:0.05, Si:1.0%, Mn:3.0%, Cr:20.0%, Ni:10.0%, Mo:0.1%, Al:2.5%, Mg:1.5%, Ti:0.05%, LiBaF 3 : 15%, BaF 2 : 3%, rare earth oxide La 2 o 3 : 0.001%, LiFeO 2 : 1%, Zr: 0.5%, P: 0.03%, S: 0.01%, 0.6% of Ce and 0.01% of La.

[0052] Among the elements in the powder core, graphite is used for carbon, ferrosilicon is used for silicon, ferromanganese is used for manganese, metal chromium powder is used for chromium, metal nickel powder is used for nickel, metal molybdenum powder is used for molybdenum, aluminum powder is used for aluminum, and metal powder is used for magnesium. Magnesium powder, titanium metal titanium powder, zirconium iron zirconium, Ce and La use L...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com