Method of using solid acid catalyst to synthesize amide-type cooling agent

A solid acid catalyst and cooling agent technology, which is applied in the preparation of carboxylic acid amides, chemical instruments and methods, preparation of organic compounds, etc., can solve the problems of waste acid discharge, non-compliance with green and environmental protection production, etc. Promote the effect of high application value and slowing down the corrosion of production equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

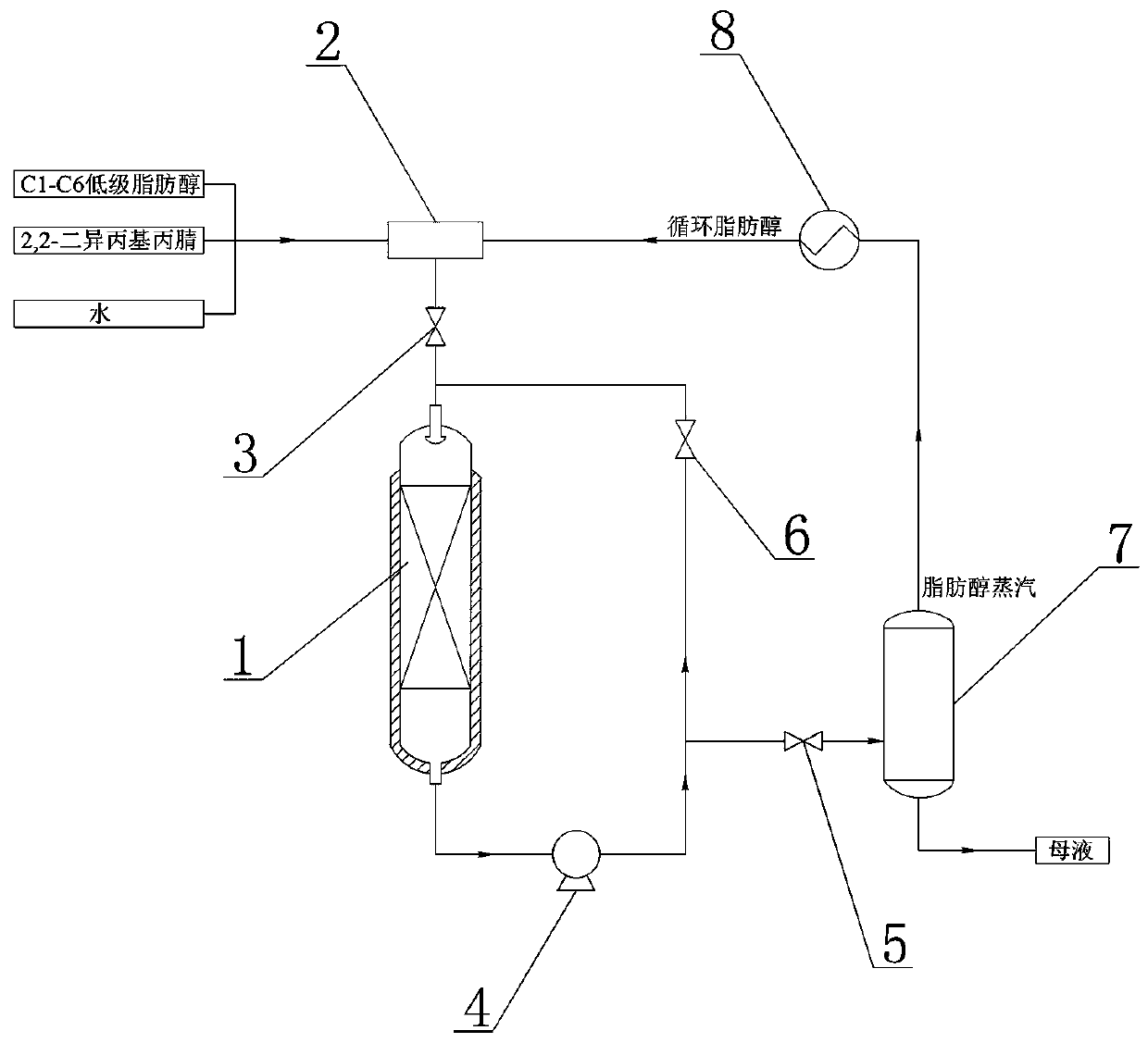

Image

Examples

Embodiment 1

[0037] (1) Preparation of wetted solid acid catalyst

[0038] Take 72g SiO 2 Heat to reflux in 100ml, 0.1mol / L HCI solution for 1 hour, filter, wash with water until neutral, and dry at 120°C for 2 hours. Treated SiO 2 Dispersed in 100g HClO 4 in ethyl acetate, stirred evenly, concentrated by heating, and activated under nitrogen protection at 80~100°C for 30h to obtain activated HClO 4 -SiO 2 Wetted solid acid catalyst.

[0039] (2) Catalytic synthesis of WS-23

[0040] Take 70g of activated HClO 4 -SiO 2 Load the wetted solid acid catalyst evenly into the fixed bed reactor 1, then mix 140g of 2,2-diisopropylpropionitrile, 256g of methanol and 1.4g of water mixture evenly through the mixer 2, and open the feed valve 3. The raw material liquid enters the fixed bed reactor 1, after the raw material liquid removes the air in the pipeline, open the discharge pump 4 and the second valve 6, so that the raw material liquid circulates in the fixed bed reactor 1, and open the ...

Embodiment 2

[0044] (1) Preparation of wetted solid acid catalyst

[0045] HClO 4 -SiO 2 The preparation of the loaded solid acid catalyst is as in Example 1, so no further details are given.

[0046] (2) Catalytic synthesis of N-ethyl-2,3-dimethyl-2-isopropylbutanamide

[0047] Take 70g of activated HClO 4 -SiO 2 Load the wet-loaded solid acid catalyst evenly into the fixed-bed reactor 1, then mix 140g of 2,2-diisopropylpropionitrile, 300g of ethanol and 1.4g of water in the mixer 2, and open the feed valve 3. The raw material liquid enters the fixed bed reactor 1, after the raw material liquid removes the air in the pipeline, open the discharge pump 4 and the second valve 6, so that the raw material liquid circulates in the fixed bed reactor 1, and open the sleeve type The heating device is used to maintain a constant temperature of 80°C for alcoholysis cycle reaction for 3h.

[0048] Sampling and analysis, after the content of 2,2-diisopropylpropionitrile in the reaction liquid is...

Embodiment 3

[0051] (1) Preparation of wetted solid acid catalyst

[0052] Take 72g SiO 2 Heat to reflux in 100ml, 0.1mol / L HCI solution for 1 hour, filter, wash with water until neutral, and dry at 120°C for 2 hours. Treated SiO 2 Dispersed in 100g H 3 PO 4 in ethyl acetate, stirred evenly, concentrated by heating, and activated under the protection of nitrogen at 80~100°C for 30 hours to obtain activated H 3 PO 4 -SiO 2 Wetted solid acid catalyst.

[0053] (2) Catalytic synthesis of WS-23

[0054] Take 65g of activated H 3 PO 4 -SiO 2 Load the wetted solid acid catalyst evenly into the fixed bed reactor 1, then mix 140g of 2,2-diisopropylpropionitrile, 256g of methanol and 1.4g of water mixture evenly through the mixer 2, and open the feed valve 3. The raw material liquid enters the fixed bed reactor 1, after the raw material liquid removes the air in the pipeline, open the discharge pump 4 and the second valve 6, so that the raw material liquid circulates in the fixed bed rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com