An environmentally friendly lubricating oil

A lubricating oil and environment-friendly technology, applied in lubricating compositions, petroleum industry, etc., can solve problems such as unsatisfactory low-temperature performance and easy solidification of rapeseed oil, and achieve better and more stable effects, wide application range, and less usage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

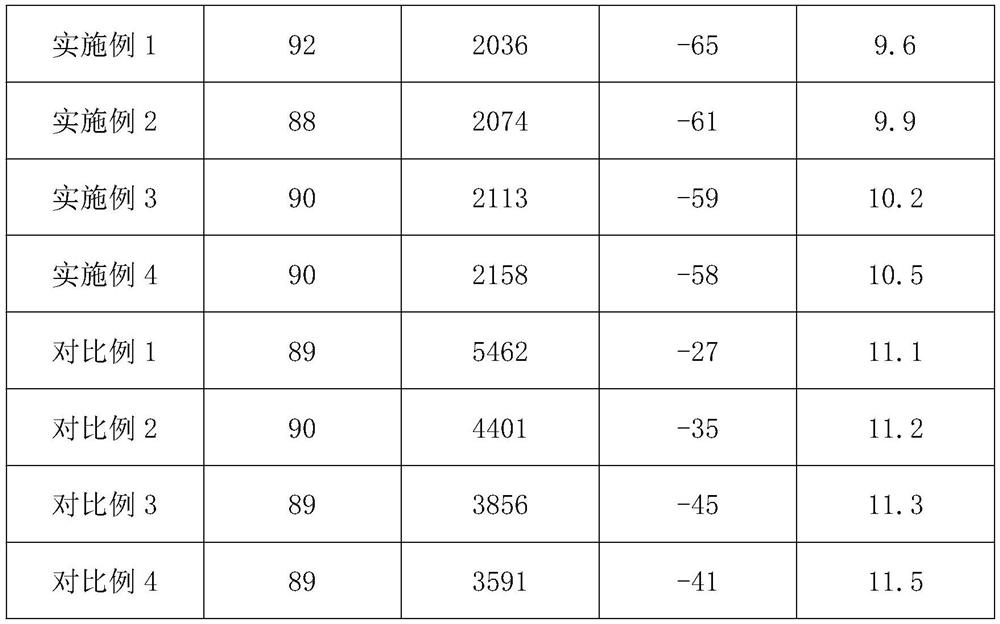

Examples

Embodiment 1

[0030] In this example, the environment-friendly lubricating oil is composed of the following components in parts by weight: 160 parts of plant-based synthetic oil, 8 parts of modified extreme pressure agent, 4 parts of viscosity index modifier, 6 parts of antiwear agent, anti-wear agent 4 parts of rust agent, 7 parts of antioxidant, 3 parts of defoamer and 130 parts of water.

[0031] Wherein, the plant-based synthetic oil is made from the following raw materials in parts by weight: 45 parts of castor oil, 95 parts of rapeseed oil, 20 parts of palm oil, 12 parts of boric acid and 10 parts of triethanolamine.

[0032] The extreme pressure agent is a modified extreme pressure agent processed through the following steps:

[0033] S1: Add absolute ethanol: extreme pressure agent: low-temperature resistant epoxy resin to the mixer at a ratio of 15:3:1 to disperse to obtain a uniform mixed solution, and use a spray dryer to dry and granulate the mixed solution to obtain an average ...

Embodiment 2

[0039] The preparation method of the modified extreme pressure agent and the environment-friendly lubricating oil in this embodiment is the same as in Embodiment 1, and will not be repeated here.

[0040] In this embodiment, the environment-friendly lubricating oil is composed of the following components by weight: 150 parts of plant-based synthetic oil, 8 parts of modified extreme pressure agent, 4 parts of viscosity index modifier, 6 parts of antiwear agent, anti-wear agent 4 parts of rust agent, 7 parts of antioxidant, 3 parts of defoamer and 140 parts of water.

[0041] Wherein, the plant-based synthetic oil is made from the following raw materials in parts by weight: 40 parts of castor oil, 90 parts of rapeseed oil, 20 parts of palm oil, 12 parts of boric acid and 10 parts of triethanolamine.

Embodiment 3

[0043] The preparation method of the modified extreme pressure agent and the environment-friendly lubricating oil in this embodiment is the same as in Embodiment 1, and will not be repeated here.

[0044]In this example, the environment-friendly lubricating oil is composed of the following components by weight: 160 parts of plant-based synthetic oil, 5 parts of modified extreme pressure agent, 4 parts of viscosity index modifier, 6 parts of antiwear agent, anti-wear agent 4 parts of rust agent, 7 parts of antioxidant, 3 parts of defoamer and 133 parts of water.

[0045] Wherein, the plant-based synthetic oil is made from the following raw materials in parts by weight: 45 parts of castor oil, 95 parts of rapeseed oil, 20 parts of palm oil, 12 parts of boric acid and 10 parts of triethanolamine.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com