Three-way catalytic converter carbon deposit cleaning agent specially used for naturally aspirated engine

A three-way catalytic converter and carbon deposit cleaning agent technology, applied in the direction of inorganic/element cleaning composition, detergent composition, detergent compounding agent, etc., can solve the poisoning failure of oxygen sensor and three-way catalytic converter, fuel consumption increase, Carbon deposits and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

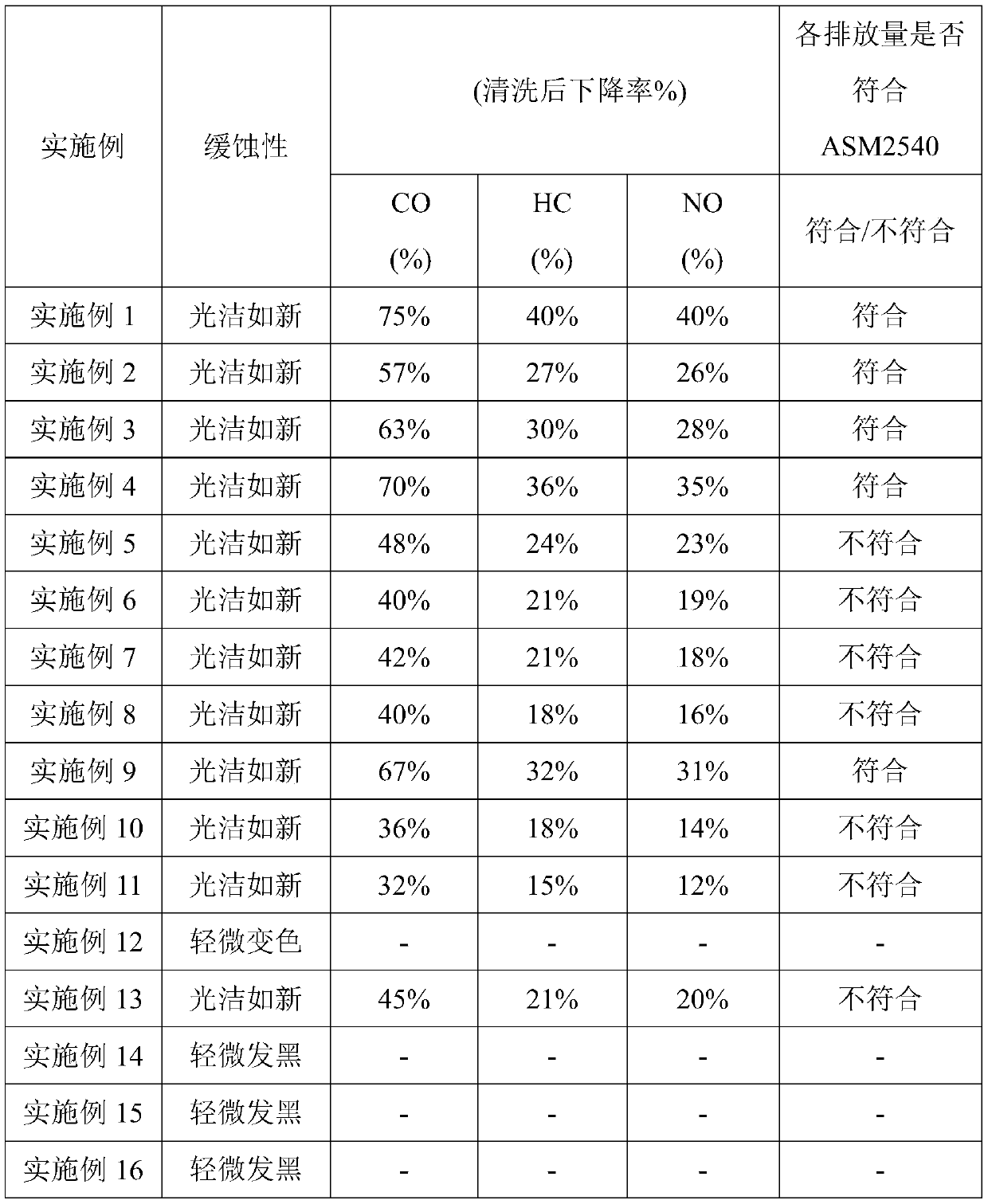

Examples

preparation example Construction

[0062] The preparation method of the cleaning agent of the present invention is as follows: uniformly mixing organic acid, modified lignosulfonate calcium, surfactant, water, bentonite and cellulose at room temperature.

[0063] The cleaning method of the cleaning three-way catalytic converter of the cleaning agent of the present invention is not limited, and can be cleaned according to any of the following methods:

[0064] (1) Method 1: Connect the disassembled three-way catalytic converter to the outlet of the water pump, then fill the cleaning tank with cleaning agent, and turn on the ultrasonic generator and water pump for cleaning;

[0065] (2) Method 2: "Drip" cleaning, insert the infusion tube into the rubber intake vacuum tube of the engine, start the engine and input the cleaning agent, the cleaning agent is heated and evaporated to produce some water vapor, and the water vapor passes through the three-way catalytic converter to clean it;

[0066] (3) Method 3: Disas...

Embodiment 1

[0068] Embodiment 1 of the present invention provides a special three-way catalytic converter carbon deposit cleaning agent for naturally aspirated engines. In parts by weight, the preparation raw materials include: 20 parts of glycolic acid, 5 parts of citric acid, and 0.8 parts of acetylated lignosulfur calcium phosphate, 1 part of dodecyl glucoside, 6 parts of sodium dodecylbenzene sulfonate, 90 parts of water, 10 parts of bentonite, 0.8 part of hypromellose (the content of methoxy in hypromellose is 28wt%, the hydroxypropyl content is 9wt%); above-mentioned raw material is mixed at room temperature and promptly obtains the three-way catalytic converter carbon deposit cleaning agent special for engine.

[0069] The preparation method of acetylated calcium lignosulfonate is as follows:

[0070] (1) Control the temperature of the reactor to 115° C., feed in nitrogen, replace the air in the reactor, add 10 parts by weight of acetic anhydride and 0.4 parts by weight of choline ...

Embodiment 2

[0074] Embodiment 2 of the present invention provides a special three-way catalytic converter carbon deposit cleaning agent for naturally aspirated engines. In parts by weight, the preparation raw materials include: 7.5 parts of glycolic acid, 2.5 parts of citric acid, and 0.1 part of acetylated lignosulfonate Calcium acid calcium, 0.2 parts of dodecyl glucoside, 0.8 parts of sodium dodecylbenzene sulfonate, 70 parts of water, 5 parts of bentonite, 0.1 part of hypromellose (methoxyl content in hypromellose is 28wt%, the hydroxypropyl content is 9wt%); above-mentioned raw material is mixed at room temperature and promptly obtains the three-way catalytic converter carbon deposit cleaning agent special for engine.

[0075] The preparation method of acetylated calcium lignosulfonate is as follows:

[0076] (1) Control the temperature of the reactor to 115° C., feed in nitrogen, replace the air in the reactor, add 10 parts by weight of acetic anhydride and 0.4 parts by weight of ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com