Quenching die for outer ring of double-row self-aligning roller bearing made of large-sized carburized steel

A self-aligning roller bearing, large-size technology, applied in the direction of quenching device, manufacturing tool, furnace type, etc., can solve the problems such as the inability to ensure the quenching quality, the increase of impurities on the outer ring surface, and the inability to keep the surface smooth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

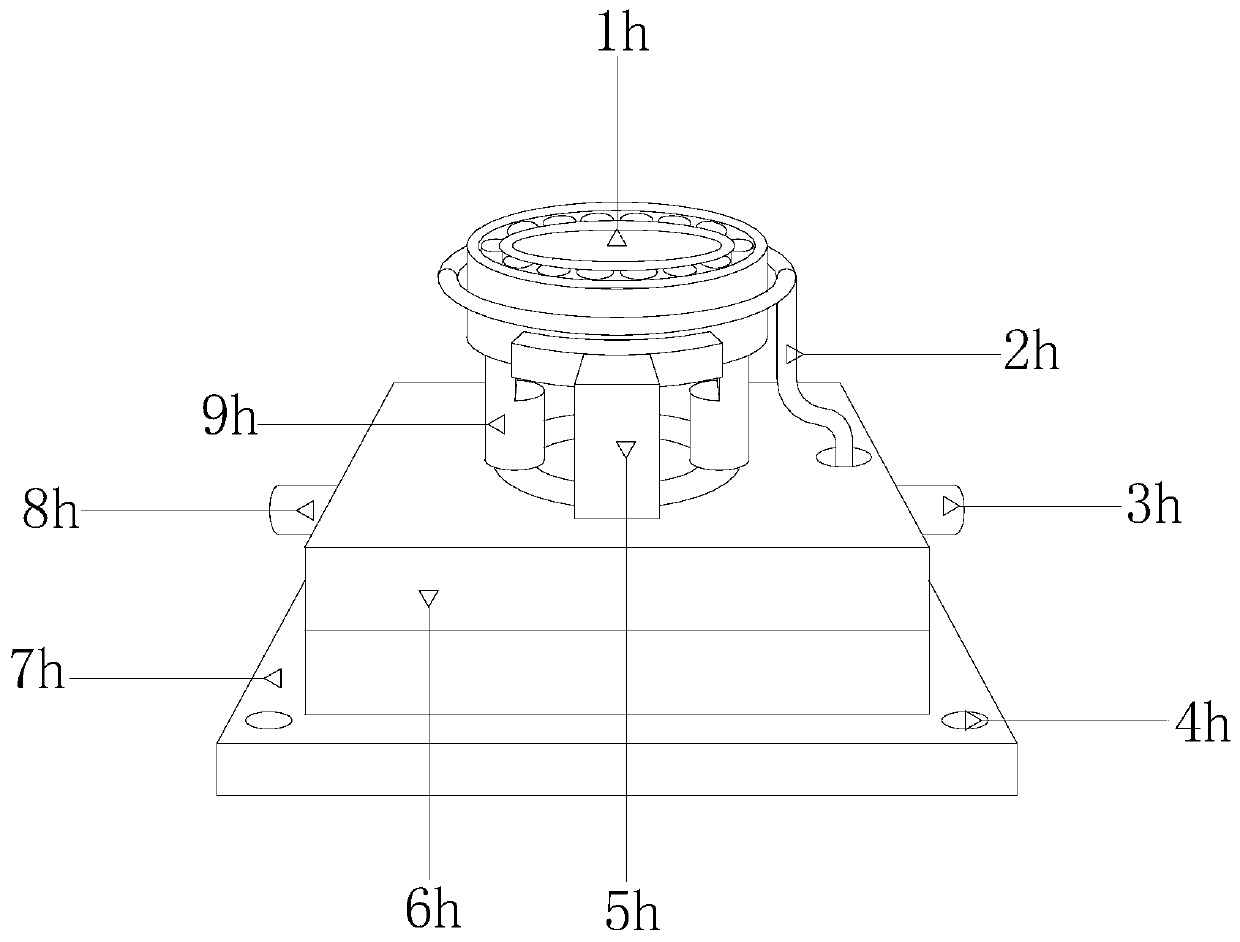

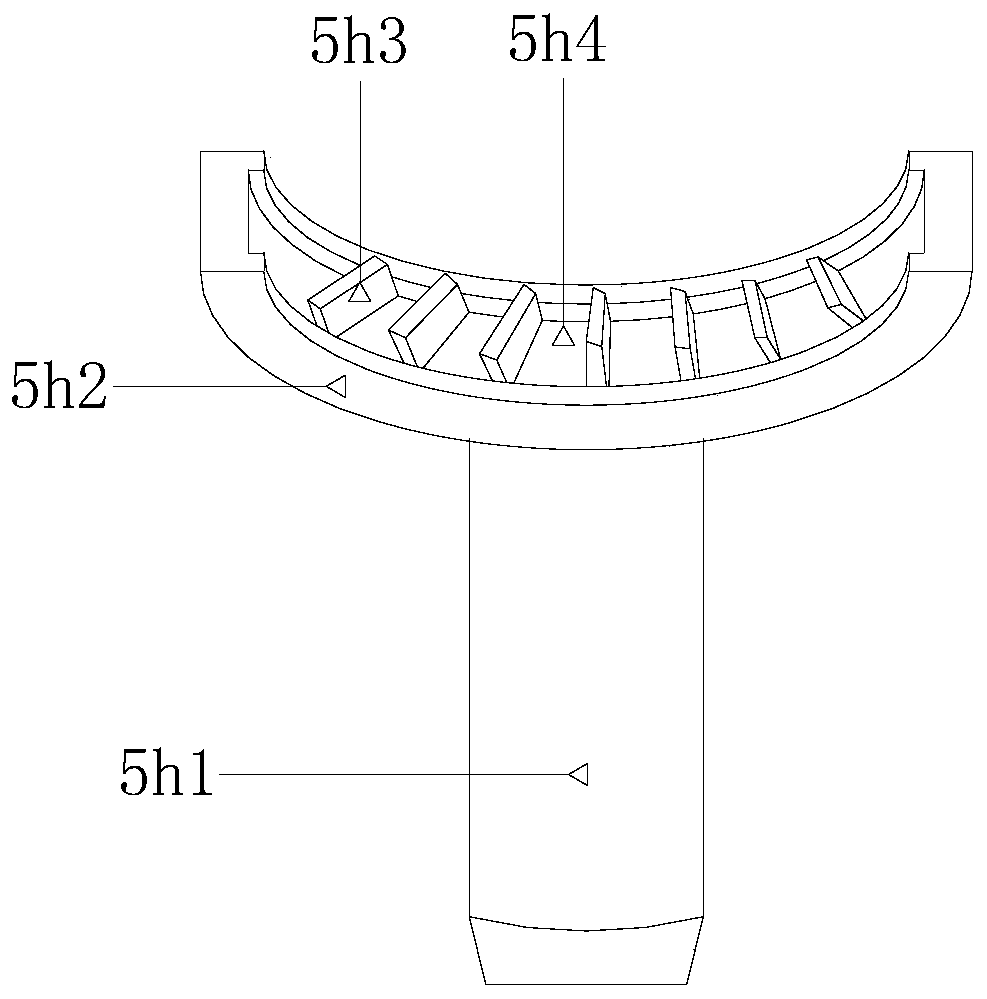

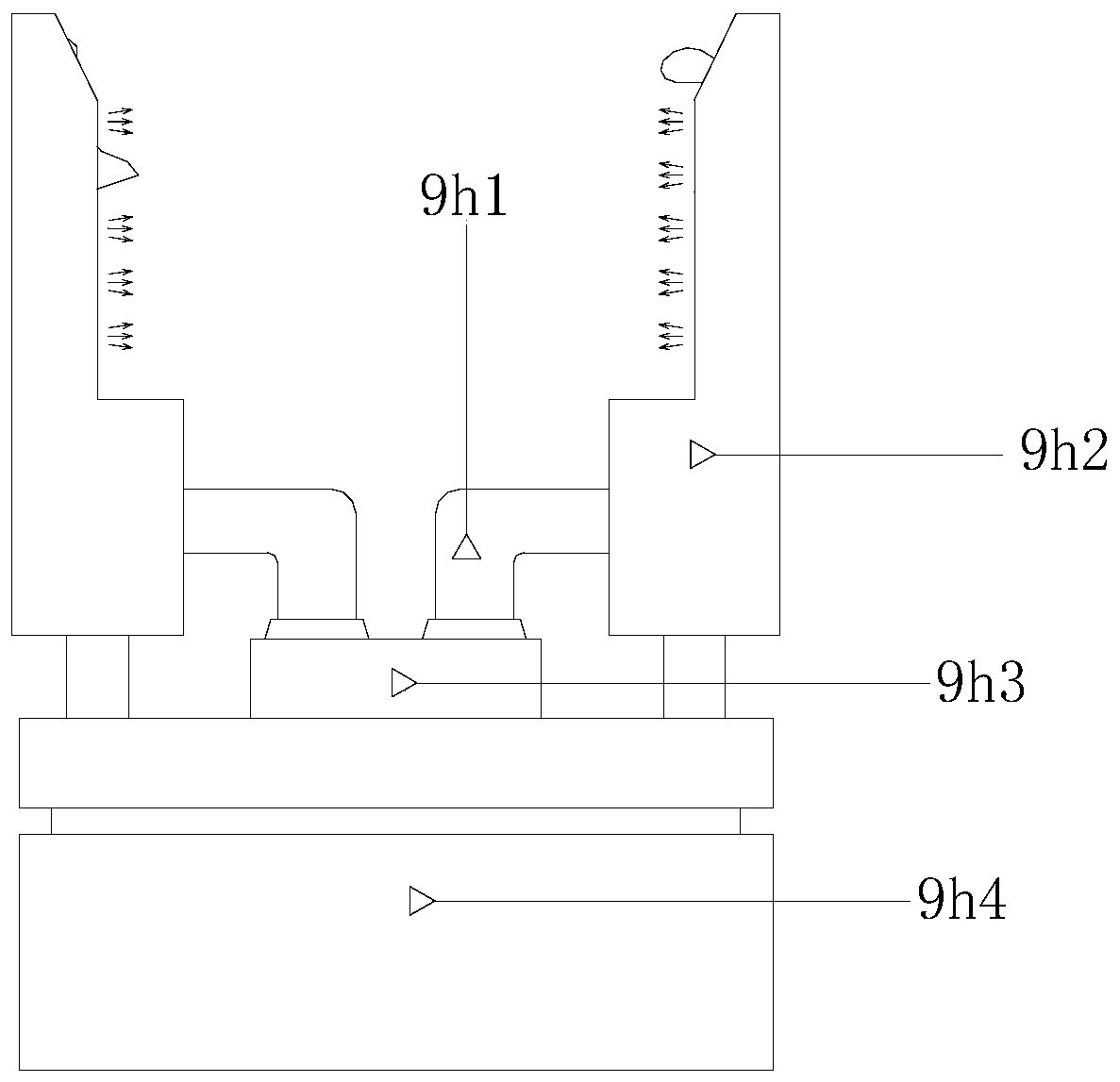

[0029] See Figure 1-Figure 6 , The present invention provides a large-size carburized steel double-row spherical roller bearing outer ring quenching mold, the structure of which includes a workpiece 1h, a quenching tube 2h, a heat conduction joint 3h, a mounting hole 4h, a smooth component 5h, and a mold base 6h, the mounting plate 7h, the cooling joint 8h, the conversion mechanism 9h, the bottom of the conversion mechanism 9h is embedded in the mold base 6h, the mold base 6h has a rectangular structure, and the bottom is provided with a mounting plate 7h, and Connected by welding, the four ends of the mounting plate 7h are respectively provided with mounting holes 4h, and are an integrated structure, the right end of the cooling joint 8h is threaded through the left side of the mold base 6h, the mold base The right side of 6h is provided with a thermally conductive joint 3h, the upper end of the quenching tube 2h is located outside the workpiece 1h, the interior of the workpi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com