Methanol catalyst protection agent and preparation method thereof

A protective agent and catalyst technology, applied in the field of methanol catalyst protective agent and its preparation, can solve the problem that sulfides and carbonyls are difficult to be effectively removed at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

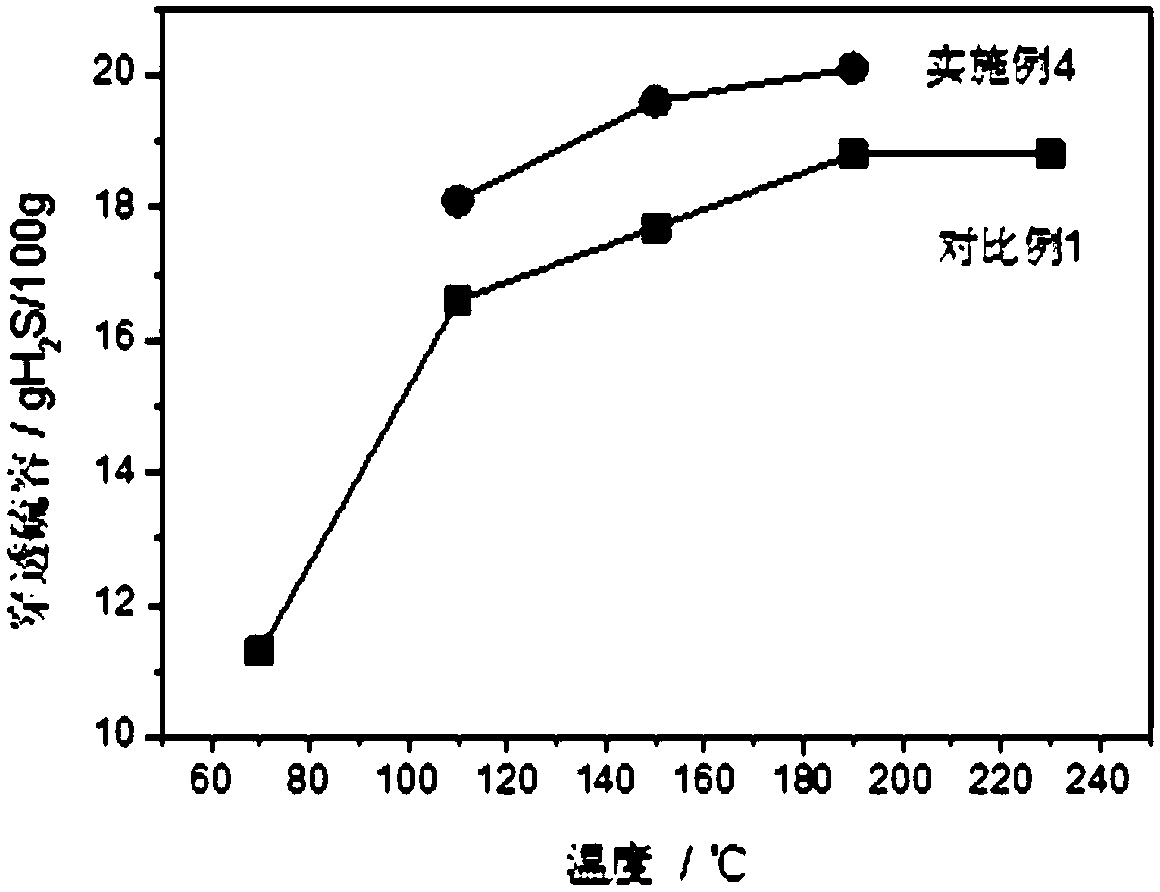

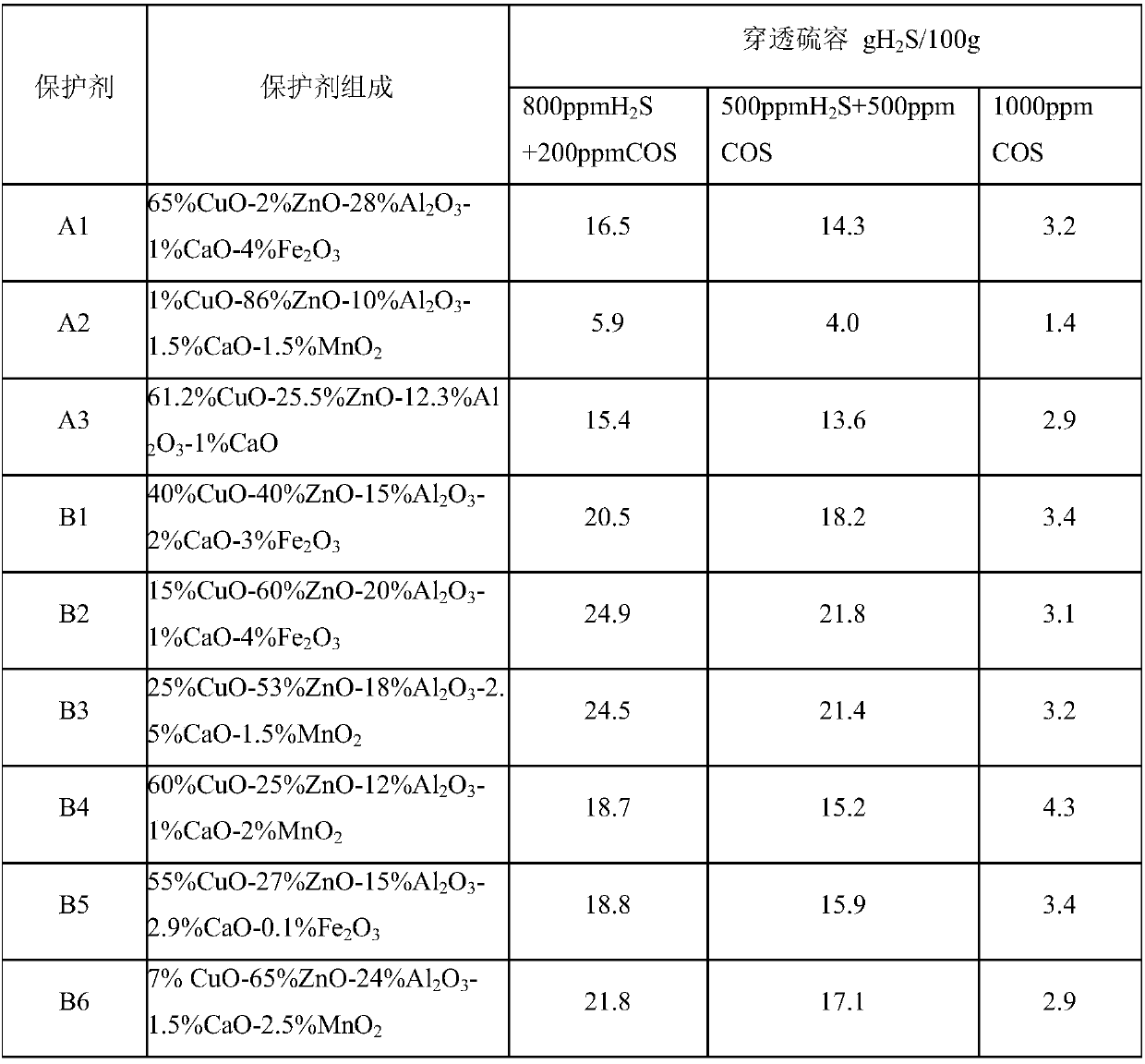

Examples

preparation example Construction

[0016] The invention provides a kind of preparation method of methanol catalyst protecting agent, comprising the following steps:

[0017] (1) Prepare a mixed aqueous solution of precursors of copper oxide, zinc oxide, aluminum oxide and calcium oxide, iron oxide and / or manganese oxide, or first prepare a mixed aqueous solution of precursors of copper oxide, zinc oxide and aluminum oxide, and then prepare calcium oxide Mixing an aqueous solution with precursors of iron oxide and / or manganese oxide; configuring an aqueous solution of a precipitating agent;

[0018] (2) Co-precipitate the precursor mixed aqueous solution of copper oxide, zinc oxide, aluminum oxide and calcium oxide, iron oxide and / or manganese oxide with the precipitant aqueous solution, or mix the precursor mixed aqueous solution of copper oxide, zinc oxide and aluminum oxide The aqueous solution mixed with the precursors of calcium oxide, iron oxide and / or manganese oxide and the aqueous solution of the precip...

Embodiment 1

[0031] CuO-ZnO-Al 2 o 3 -CaO-Fe 2 o 3 Preparation of catalyst protection agent: adopt the method of step-by-step co-precipitation, the specific process is: first mix a certain proportion of CuO, ZnO and Al 2 o 3 The precursors of the precursors are dissolved in water together to prepare a mixed solution of Cu, Zn and Al precursors, and then a certain amount of CaO and Fe 2 o 3 The precursor is dissolved in water to prepare a precursor mixed solution containing Ca and Fe, wherein CuO / ZnO (weight ratio)=1 / 1, CuO / Al 2 o 3 (weight ratio) = 2.67 / 1, CuO / CaO (weight ratio) = 20 / 1, CuO / Fe 2 o 3 (weight ratio)=13.3 / 1, and prepare corresponding amount of Na 2 CO 3 and NaHCO 3 The mixed solution of which, Na 2 CO 3 / NaHCO 3 (molar ratio) = 10 / 1, then at 75 ° C, the precursor solution is precipitated in two steps, wherein the precursor solution and Na 2 CO 3 and NaHCO 3 The drop rate of the mixed aqueous solution is matched to control the pH value of the precipitation to ...

Embodiment 2

[0033] CuO-ZnO-Al 2 o 3 -CaO-Fe 2 o 3 The preparation of the catalyst protection agent: adopt the co-precipitation method, the specific process is: first mix a certain ratio of CuO, ZnO, Al 2 o 3 , CaO and Fe 2 o 3 The precursors of the precursors are dissolved in water together to prepare a precursor mixed solution of Cu, Zn, Al, Ca and Fe, wherein CuO / ZnO (weight ratio)=1 / 4, CuO / Al 2 o 3 (weight ratio) = 1 / 1.33, CuO / CaO (weight ratio) = 15 / 1, CuO / Fe 2 o 3 (weight ratio)=3.75 / 1, and prepare corresponding amount of Na 2 CO 3 and NaHCO 3 The mixed solution of which, Na 2 CO 3 / NaHCO 3 (molar ratio) = 5 / 1, then at 70 ° C, the precursor solution is precipitated in two steps, wherein the precursor solution and Na 2 CO 3 and NaHCO 3 The drop rate of the mixed aqueous solution is matched to control the pH value of the precipitation to be 7-9. After the precipitation is completed, it is aged at 70°C for 2 hours, then dried at 120°C for 12 hours, and roasted at 280°C ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com