Preparation method of flexible hydrophobic dielectric film for electrowetting device

A dielectric film and electrowetting technology, applied in the field of material preparation, can solve the problems of small dielectric constant, poor substrate adhesion, unfavorable mold rotation process, etc., and achieve the effect of simple preparation method and easy material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

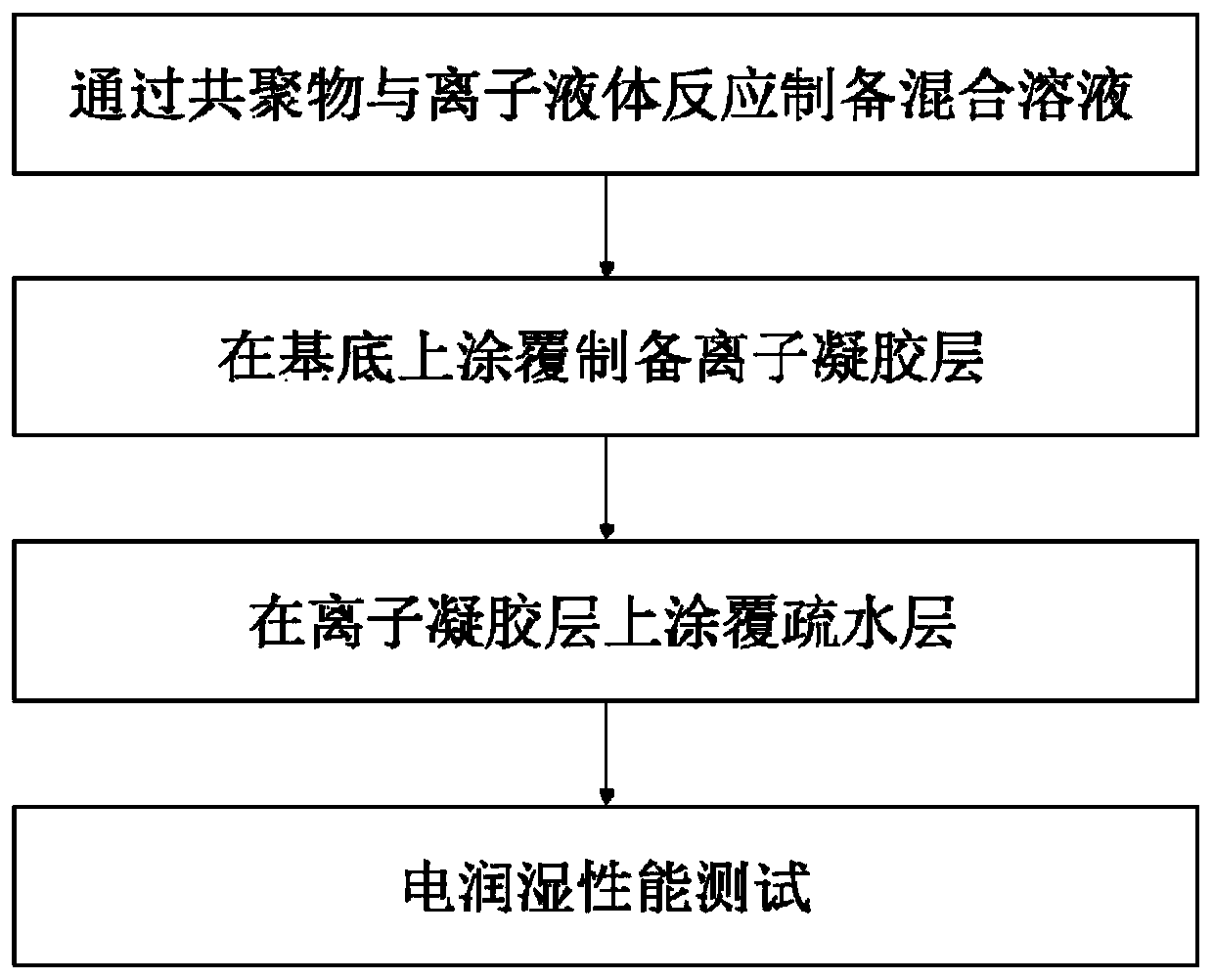

[0032] refer to figure 1 , the preparation method according to the present invention comprises the following steps:

[0033] 1) adding the fluoropolymer and the ionic liquid to the solvent to react to obtain a mixed solution, and directly coating the mixed solution on the surface of the substrate;

[0034] 2) curing by heating in a vacuum oven at 70 to 110°C for 4 to 40 hours to obtain an ion gel layer;

[0035] 3) Coating a hydrophobic layer on the surface of the ion gel layer to obtain a hydrophobic dielectric composite film, which can be used in electrowetting devices.

[0036] Preferably, as step 1), the fluorine-containing polymer is selected from poly(vinylidene fluoride-co-hexafluoropropylene) (PVDF-HFP) or poly(styrene-b-methyl methacrylate-b- Styrene) ([SMS]). Among them, vinylidene fluoride-co-hexafluoropropylene is a copolymer of vinylidene fluoride and hexafluoroisobutylene, and the copolymerization makes the crystallinity lower, so it has a larger amorphous reg...

Embodiment 1

[0056] 1. Synthesis of gel solution. Add 0.2 g of fluorine-containing polymer P(VDF-HFP) particles into a 50 mL flask, the weight-average molecular weight of the fluorine-containing polymer P(VDF-HFP) is 400,000, and the number-average molecular weight is 130,000. 0.7 g of ionic liquid [EMIM][TFSI] and 9.1 g of acetone were added. The reactants were magnetically stirred in an oil bath reactor at 60° C. for 3.5 hours to ensure that the fluoropolymer and the ionic liquid could be completely dissolved and reacted to obtain a mixed solution.

[0057] 2. The gel solution is spin-coated to form a film. Firstly, ultrasonically clean the ITO glass substrate, and dry it with nitrogen gas for later use. Then drop the mixed solution prepared in step 1) on it, adjust the rotation speed to 1500r / min, and spin coat to obtain an ion gel layer. The samples were put into a vacuum drying oven for heating and curing at a temperature of 70°C for 30 hours. Ensure that the solvent is completely...

Embodiment 2

[0061] 1. Synthesis of gel solution. Add 0.7 g of fluoropolymer P(VDF-HFP) particles into a 50 mL flask, the fluoropolymer has a weight molecular weight of 400,000 and a number average molecular weight of 130,000. 2.6 g of ionic liquid [EMIM][TFSI] and 6.7 g of acetone were added. The reactant was magnetically stirred in an oil bath reactor at 60° C. for 3.5 h to ensure that the copolymer and the ionic liquid could be completely dissolved and reacted to obtain a mixed solution.

[0062] 2. The gel solution is spin-coated to form a film. Firstly, ultrasonically clean the ITO glass substrate, and dry it with nitrogen gas for later use. Then drop the mixed solution prepared in step 1) on it, adjust the rotation speed to 1500r / min, and spin coat to obtain an ion gel layer. The samples were put into a vacuum drying oven for heating and curing at a temperature of 70°C for 30 hours. Ensure that the solvent is completely evaporated to obtain an ion gel layer. The thickness of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com