Enzyme/manganese phosphate trihydrate/graphene oxide nano composite material and preparation method thereof

A technology of nanocomposite materials and manganese phosphate trihydrate, applied in the field of chemical materials, to achieve the effect of mild and simple experimental process and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

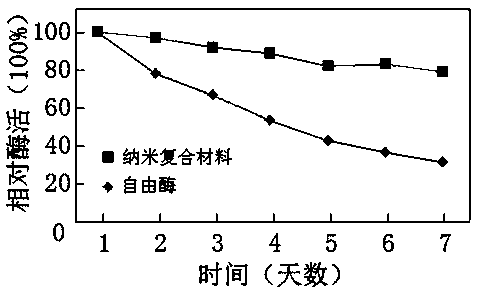

[0031] An enzyme / manganese salt / graphene oxide nanocomposite material, comprising the following components in mass percentage: 22.36% of laccase, 73.17% of manganese phosphate trihydrate crystals, and 4.47% of GO.

[0032] (1) Preparation method of nanocomposite materials

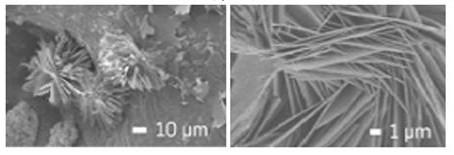

[0033] Dissolve 10 mg laccase in PBS (0.2 mol / L) with a pH of 5.7, add 0.667 mL of 120 mM manganese chloride solution and let stand for 18 h, then dissolve 2 mg GO in the above solution, at 25 °C , and reacted in a shaker at 140rpm for 24 h. Then the precipitate was separated, washed and freeze-dried in a vacuum freeze dryer at -20 °C for 6 h. The obtained enzyme / manganese salt / graphene oxide nanocomposite is scanned by electron microscope, and the results are as follows: figure 1 . Depend on figure 1 It can be seen that the composite material presents a unique wheel-shaped flower-like nanostructure.

[0034] (2) Determination method and results of laccase activity in nanocomposite materials

[0035] ...

Embodiment 2

[0039] An enzyme / manganese phosphate trihydrate / graphene oxide nanocomposite material, comprising the following components in mass percentage: 19.18% of carbonic anhydrase, 78.43% of manganese phosphate trihydrate crystals, and 2.40% of GO.

[0040] (1) Preparation method of nanocomposite materials

[0041] Dissolve 8 mg of carbonic anhydrase in PBS (0.2 mol / L) with a pH of 8.5, add 0.667 mL of 120 mM manganese chloride solution and let stand for 16 h, then dissolve 1 mg of GO in the above solution, at 25 °C , and reacted in a shaker at 140rpm for 20 h. Afterwards, the precipitate was separated, washed and freeze-dried in a vacuum freeze-dryer at -20°C for 5 h. Electron microscopy scanning of the obtained enzyme / manganese salt / graphene oxide nanocomposite showed a unique wheel-shaped flower-like nanostructure.

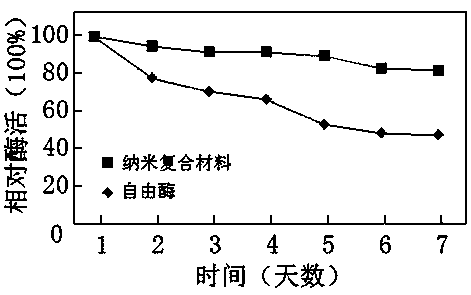

[0042] (2) Determination method and results of carbonic anhydrase activity in nanocomposite materials

[0043]Mix 0.3 mL of the enzyme solution to be tested, 2.4 mL...

Embodiment 3

[0046] An enzyme / manganese phosphate trihydrate / graphene oxide nanocomposite material, comprising the following components in mass percentage: 20.82% of carbonic anhydrase, 75.71% of manganese phosphate trihydrate crystals, and 3.47% of GO.

[0047] (1) Preparation method of nanocomposite materials

[0048] Dissolve 9 mg of carbonic anhydrase in PBS (0.2 mol / L) with a pH of 8.5, add 0.667 mL of 120 mM manganese chloride solution and let it stand for 20 h, then dissolve 1.5 mg of GO in the above solution, at 25 °C , reacted for 24 h in a shaker at 140 rpm, and then the precipitate was separated, washed and freeze-dried in a vacuum freeze-dryer at -20 °C for 7 h. Electron microscopy scanning of the obtained enzyme / manganese salt / graphene oxide nanocomposite showed a unique wheel-shaped flower-like nanostructure.

[0049] (2) Determination method and results of carbonic anhydrase activity in nanocomposite materials

[0050] Mix 0.3 mL of the enzyme solution to be tested, 2.4 mL...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com