Medium immobilized enzyme and preparation method and application thereof

A technology for immobilizing enzymes and media, applied to biochemical equipment and methods, immobilized on or in inorganic carriers, fixed on/in organic carriers, etc., can solve the problem of low enzyme loading and achieve loading High enzyme content, high stability, and high enzyme activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

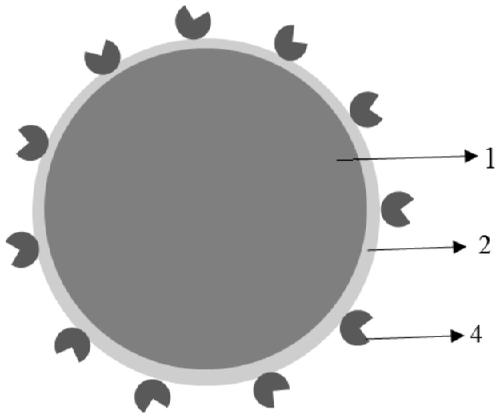

[0061] This embodiment provides a medium-immobilized enzyme, such as figure 1 As shown, it consists of substrate 1, immobilized coating 2 and enzyme molecule 4.

[0062] Wherein, the matrix is sodium alginate microspheres, chitosan microspheres and montmorillonite microspheres with an average particle size of 1-3mm, and the raw materials for the fixed coating include tannic acid buffer solution and 3-aminopropyltriethoxysilane ethanol solution, the enzyme molecule is horseradish peroxidase.

[0063] The preparation method is as follows:

[0064] (1) Dissolve tannic acid in 25mL10mM Tris-HCl buffer solution (pH=8.5) to obtain a tannic acid buffer solution with a concentration of 2g / L, and dissolve 3-aminopropyltriethoxysilane in anhydrous In ethanol (analytical pure), obtain the 3-aminopropyltriethoxysilane solution that concentration is 10g / L; 5:1 mixed to obtain a mixed solution;

[0065] (2) Sodium alginate microspheres, chitosan microspheres and montmorillonite micros...

Embodiment 2-7

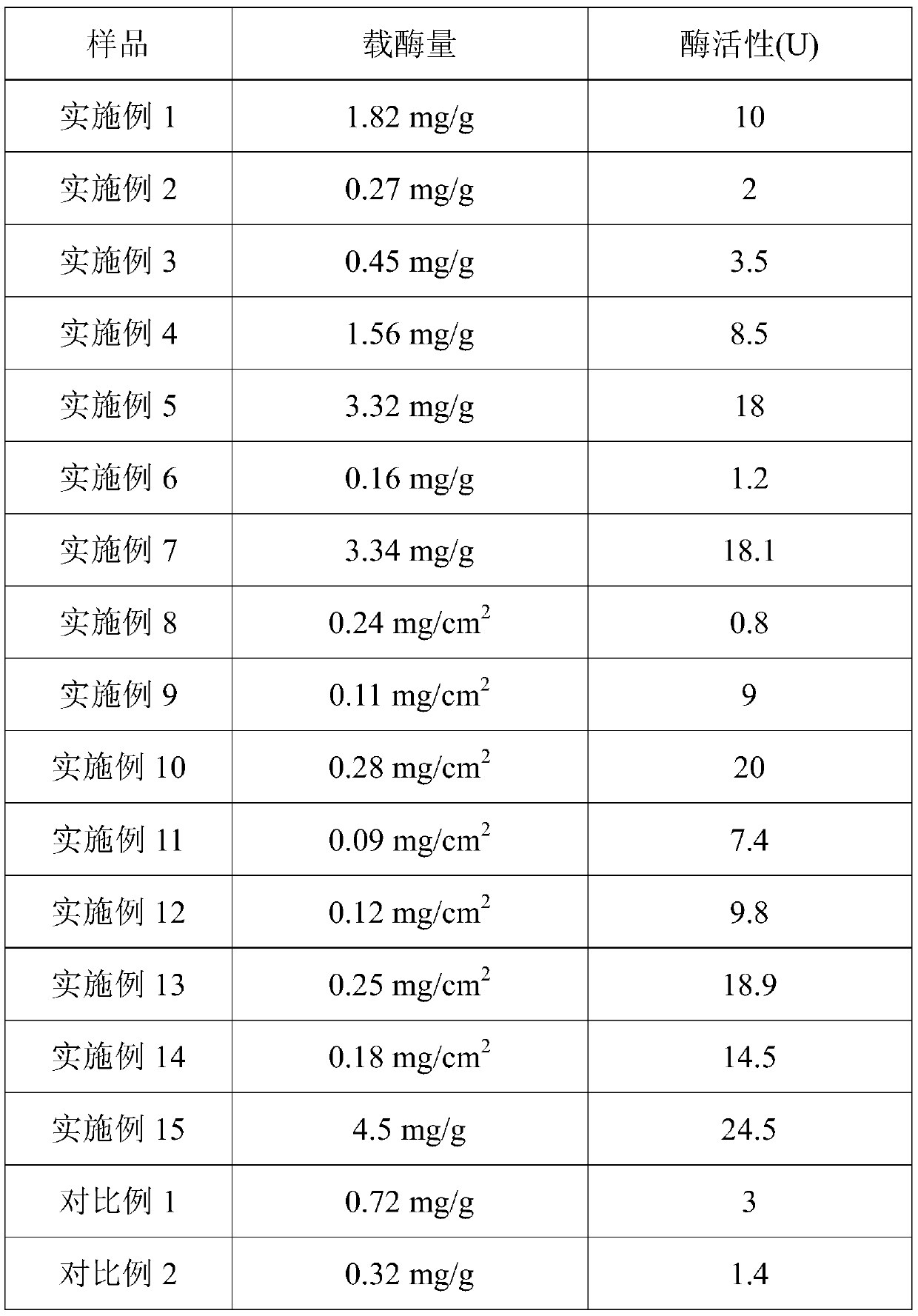

[0068] The difference with Example 1 is that, in the present example, the volume ratio of tannic acid buffer solution and 3-aminopropyltriethoxysilane solution is 0.2:1 (Example 2), 1:1 (Example 2). 3), 2:1 (Example 4), 8:1 (Example 5), 0.1:1 (Example 6), 10:1 (Example 7).

Embodiment 8

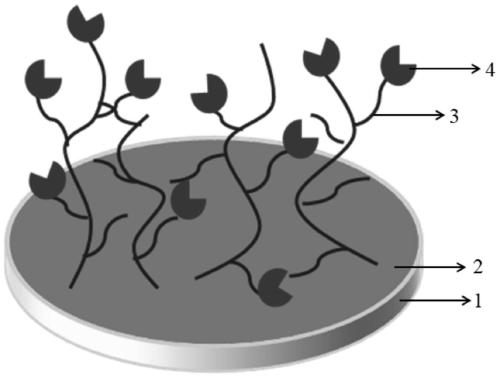

[0070] This embodiment provides a medium immobilized enzyme, which consists of a matrix, an immobilized coating and enzyme molecules.

[0071] Wherein, the substrate is a nylon film, the raw material of the fixed coating includes a tannic acid buffer solution and a 3-aminopropyltriethoxysilane ethanol solution with a solution volume ratio of 8:1, and the enzyme molecule is sucrase.

[0072] The preparation method is as follows:

[0073] (1) With reference to Example 1, the difference is that the solution volume ratio of tannic acid and 3-aminopropyltriethoxysilane is 8:1;

[0074] (2) Place the nylon membrane in the mixed solution of step (1), rinse it with deionized water after stirring at 150rpm / min at room temperature for 18h, to obtain a substrate with a fixed coating;

[0075] (3) Place the substrate with a fixed coating obtained in step (2) in 0.15g / L sucrase solution (pH=5.010mM acetic acid buffer solution), stir at 150rpm / min at room temperature for 2h, then rinse wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com