Explosion-proof combined permanent magnet or switched reluctance electromechanical all-in-one machine and assembling method

A switched reluctance and combined technology, applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve the problems of coal safety requirements for mining equipment, unusable coal mine underground working environment, oil cooling and oil immersion structure maintenance and other issues to achieve the effect of saving manpower, saving initial investment and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing, the present invention will be further described by examples.

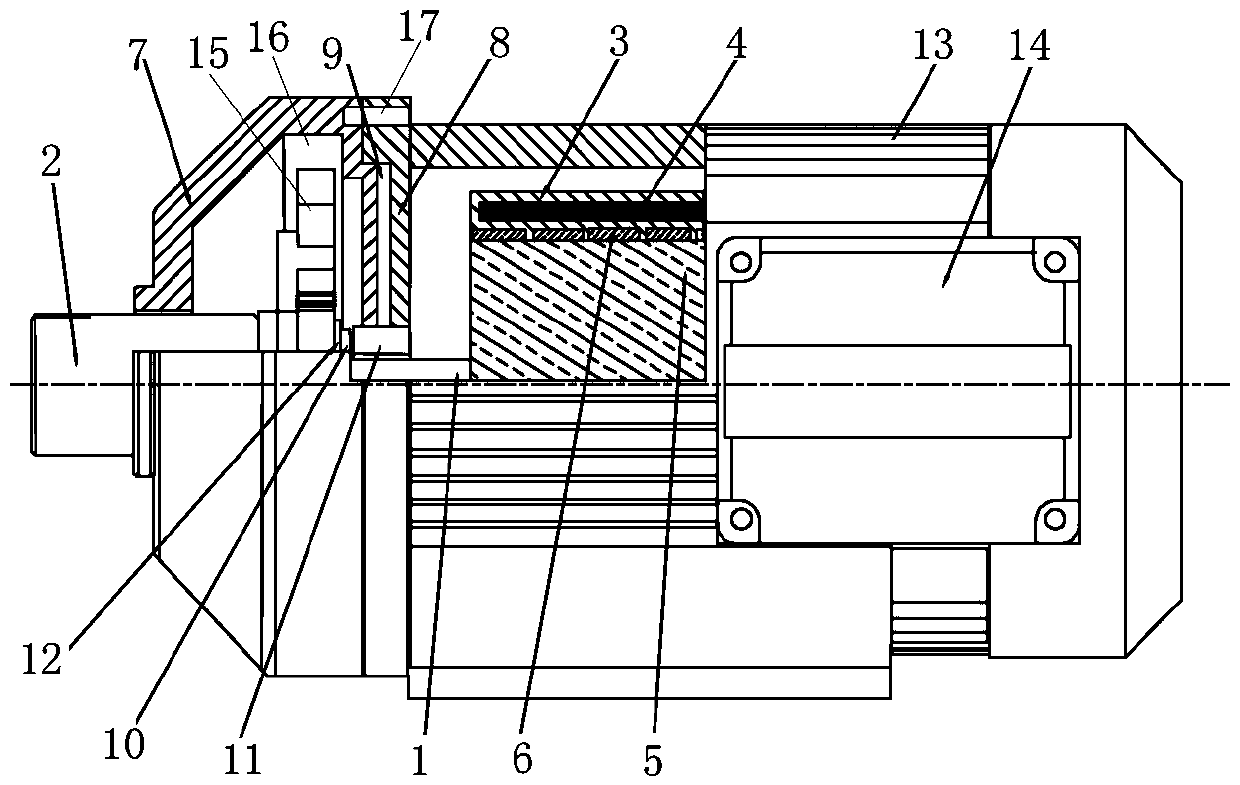

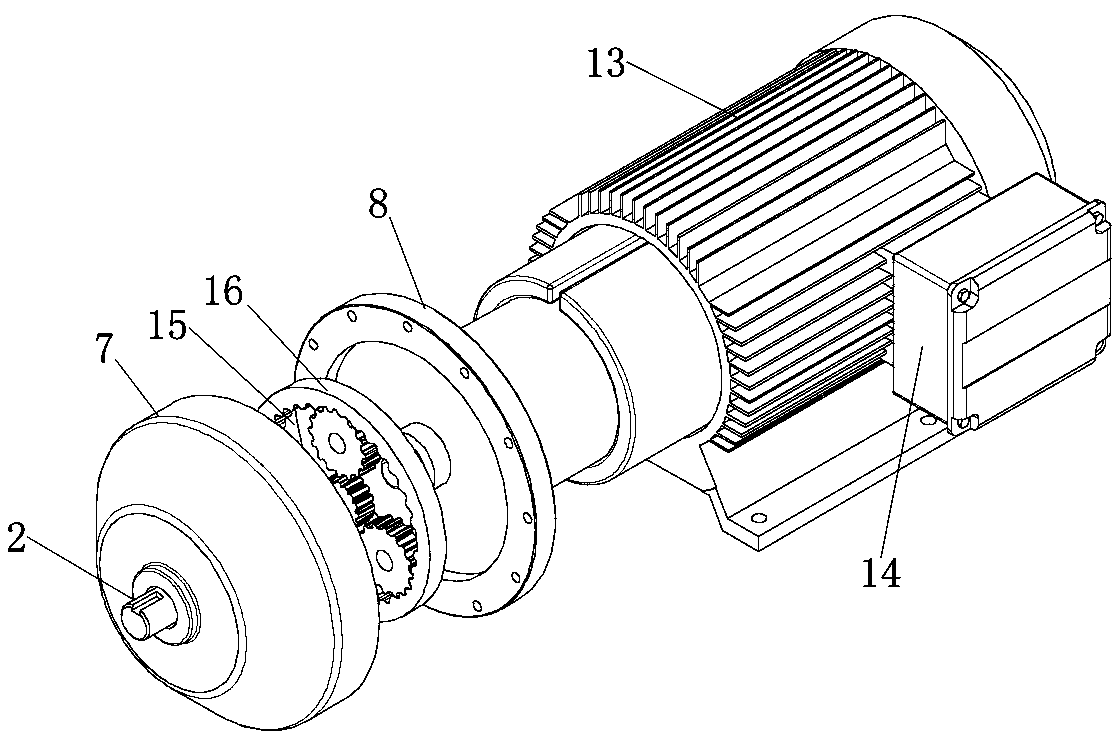

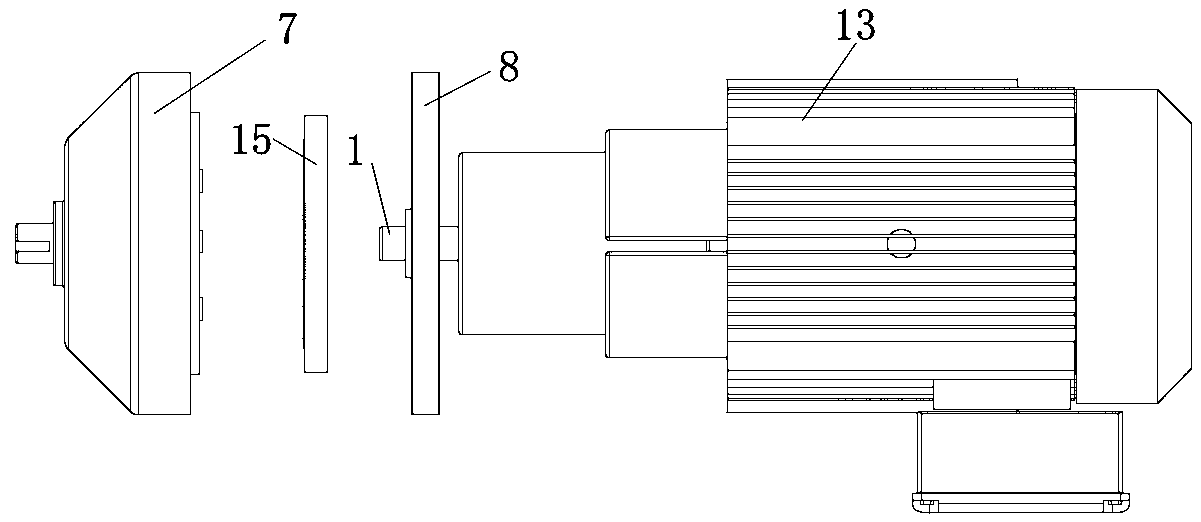

[0027] An explosion-proof combined permanent magnet or switched reluctance electromechanical integrated machine, including a casing 13, a rotor shaft 1, an output shaft 2, a permanent magnet stator core 3, a stator winding 4, a rotor core 5, a magnetic steel 6 and a planetary reducer A device 15; a bearing 11 is arranged on the front cover 8 of the casing 13, and the rotor shaft 1 is arranged on the bearing 11; a permanent magnet stator core 3 is arranged inside the casing 13, and a stator winding 4 is arranged on the permanent magnet stator core 3 , the rotor shaft 1 is provided with a rotor core 5, and the rotor core 5 is provided with a magnetic steel 6; the planetary reducer 15 is provided on a reducer base 16, and the input shaft 10 of the reducer is provided with a spline groove 12 and a bearing 11 The end of the outer rotor shaft 1 and the reducer input ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com