A kind of germanium selenide target and preparation method thereof

A germanium selenide and target technology, applied in the field of photoelectric material production, can solve the problems of high energy consumption, easy oxidation, easy to cause pollution and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The invention provides a preparation method of a germanium selenide target material, comprising the following steps:

[0033] A) heating the germanium block to 980~1050 ℃, after keeping warm to obtain germanium solution;

[0034] B) heating the selenium block to 230-250°C, after heat preservation, the selenium block is melted and dropped into the germanium solution to obtain a mixed smelting solution;

[0035] C) heating the mixed smelting solution at 980-1050° C. for 30-60 min, and cooling to obtain a selenium-germanium alloy;

[0036] D) ball milling the selenium-germanium alloy, and the obtained selenium-germanium powder is sintered by vacuum hot pressing to obtain a germanium-selenide target;

[0037] Steps A), B) and C) are carried out under vacuum.

[0038] The raw materials used in the preparation method provided by the present invention are germanium blocks and selenium blocks. The present invention has no special limitation on the purity of the germanium and...

Embodiment 1

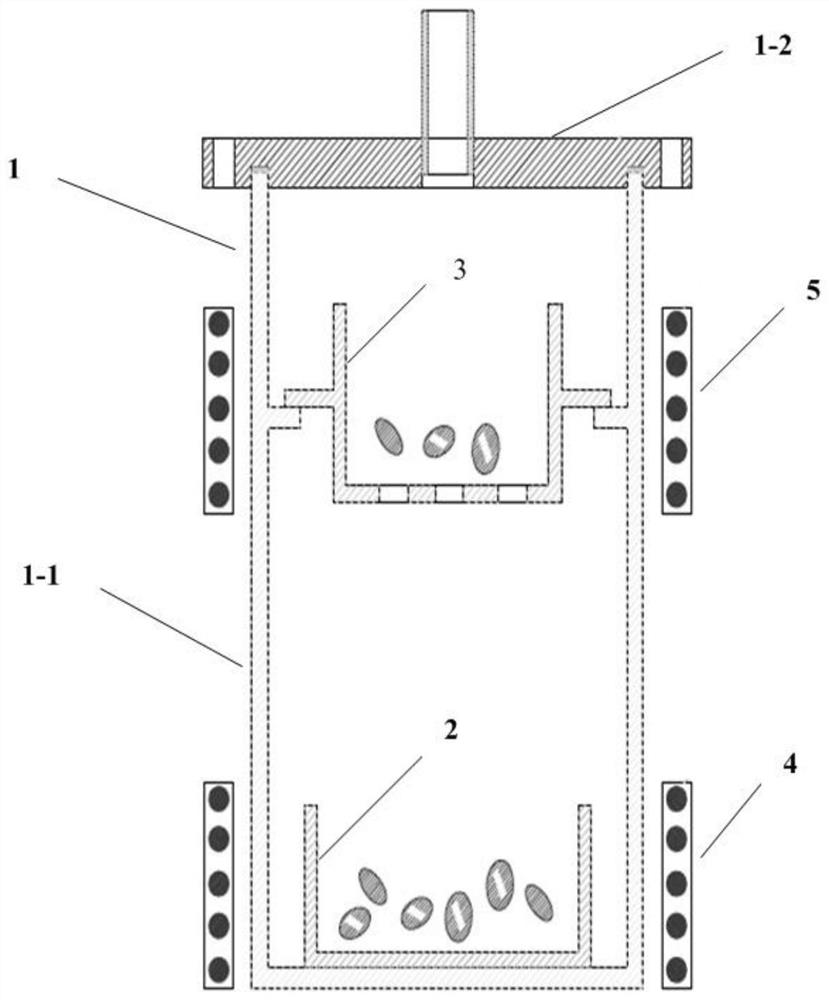

[0086] using as figure 1 The shown preparation apparatus prepares the selenium germanium alloy:

[0087] Cuboid-shaped box: a vacuum port is provided on the box cover of the box, and the vacuum port is connected to a vacuum pump;

[0088] a frit crucible arranged in the box, and the germanium block is heated in the frit crucible;

[0089] a quartz funnel (the aperture of the quartz funnel is 0.8 mm) arranged in the box, and the selenium block is heated in the quartz funnel;

[0090] The quartz funnel is placed above the frit crucible, so that the melt in the quartz funnel drops into the frit crucible; the vertical distance between the frit crucible and the quartz funnel is 65 cm.

[0091] a first heating device (ie a high temperature heating furnace), the first heating device is used to heat the crucible; the first heating device is arranged on the outer wall of the upper part of the box;

[0092] A second heating device (ie a low temperature heating furnace), the second he...

Embodiment 2

[0102] using as figure 1 The shown preparation device prepares a selenium-germanium alloy, which is different from Example 1 in that the aperture of the quartz funnel is 1 mm.

[0103] Specific operations:

[0104] Open the box cover, place the germanium block in the melting crucible, place the selenium block in the quartz funnel, close the box cover, put a vacuum flange between the box body and the box cover, and the vacuum degree of vacuuming is 2.5Pa. The molar ratio of germanium block and selenium block is 1:1.012.

[0105] Turn on the first heating device, heat the temperature to 1000°C, keep the temperature for 30min, and obtain the germanium solution; then turn on the second heating device, heat it to 240°C at 12°C / min, keep the temperature for 90min, the selenium block is melted, and drop into the germanium solution , to obtain a mixed molten liquid.

[0106] The second heating device was turned off, the first heating device heated the mixed smelting liquid at 1000°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com