Refractory brick measuring system based on machine vision

A technology of machine vision and refractory bricks, which is applied in the direction of measuring devices, instruments, optical testing defects/defects, etc., can solve problems affecting steel production, prone to misjudgment, and failure to build, so as to shorten the production cycle, simplify the mechanical structure, The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

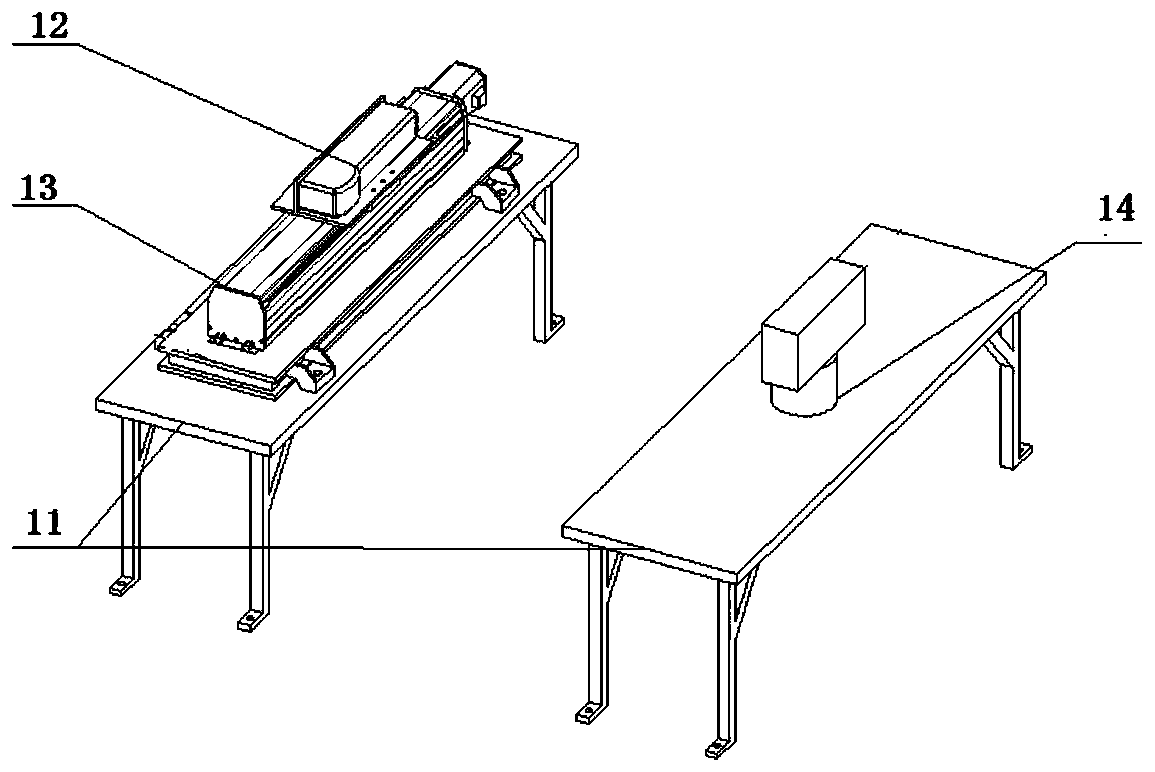

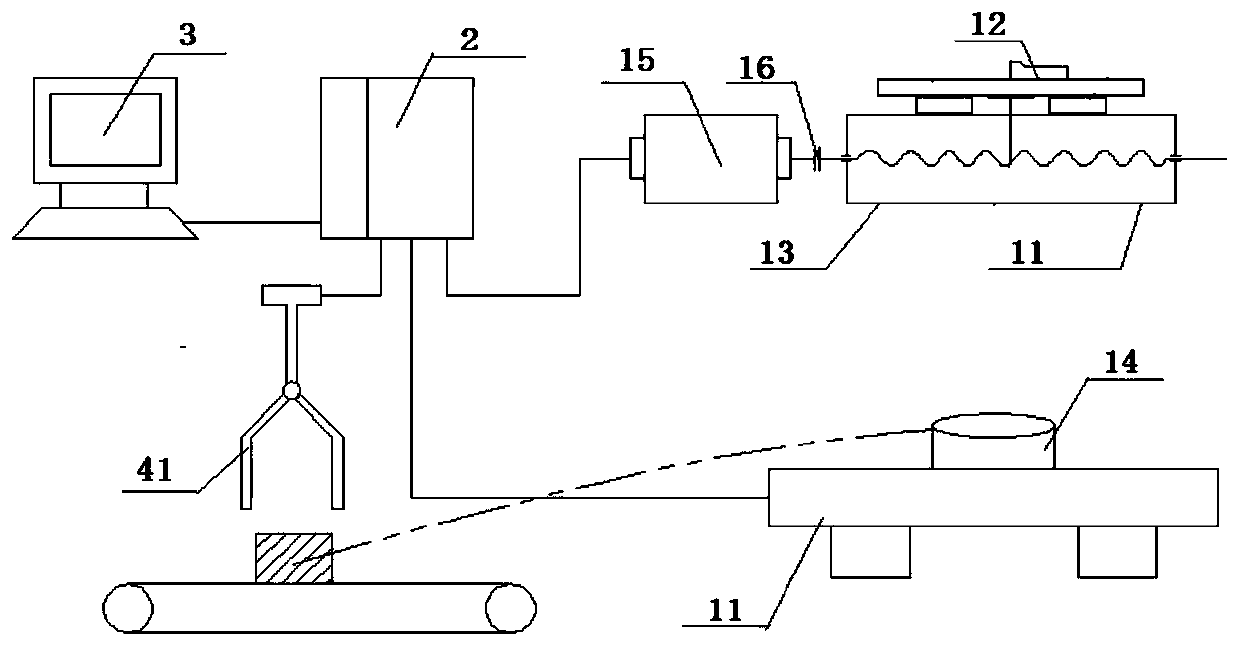

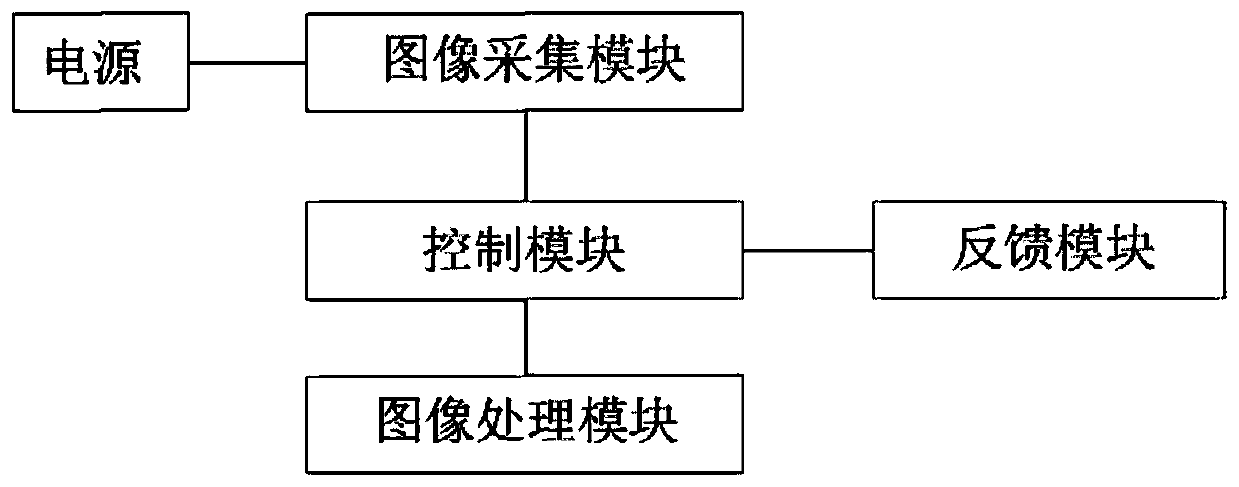

[0066] Such as Figure 1-3 As shown, the refractory brick measuring device based on machine vision includes an image acquisition module 1, a control module 2, an image processing module 3 and a feedback module 4. The image acquisition module 1 has a base 11, and the base 11 is provided with a three-structure light laser sensor The guide rail 13 of 12, the stepper motor 15 drives the three-structured light laser sensor 12 to move through the coupling 16, the turntable 14 carrying the refractory brick is fixed on the base 11, and the three-structured light laser sensor 12 is aligned with the surface of the refractory brick to be tested and scanned 4 end faces of the refractory bricks to be tested; the input end of the control module 2 is connected with the image acquisition module 1, and the output end of the control module 2 is respectively connected with the image processing module 3 and the feedback module 4, the feedback module 4 includes a travel switch, and executes the eli...

Embodiment 2

[0219] The scratches on the surface of refractory bricks are relatively shallow, but in the process of smelting steel, the penetration corrosion phenomenon will become more and more serious with the passage of time, which will eventually affect the service life of refractory bricks and bring quality and performance impact. Therefore, the surface scratch detection of refractory bricks is particularly important.

[0220] A method for identifying scratches on the surface of refractory bricks based on frequency domain filtering enhancement, including:

[0221] Step 1: collect the original image of the refractory brick, the original image is a color image, carry out channel separation to the original color image of the refractory brick, and obtain the G channel image;

[0222] Step 2: Process the G channel image from the perspective of the frequency domain, perform two-dimensional discrete Fourier transform and frequency domain filtering and smoothing on the G channel image, and o...

Embodiment 3

[0293] In the production process of refractory bricks, in addition to the surface scratches caused by contact, some deep defects will also be caused by the loss of the mold: pits, pockmarked surfaces and missing corners and edges. The image data collected by the Gocator2350 sensor is the color point cloud data that is fused together with the image data and the 3D point cloud. In this regard, depth defects can be analyzed from the height information in the point cloud data.

[0294] The data collected by the sensor is color point cloud data, and its coordinate system is based on the sensor pose. Therefore, it is first necessary to fit the measured upper surface of the refractory brick, and perform height segmentation along its normal direction to obtain depth defect information.

[0295] A method for identifying depth defects in refractory bricks based on height histogram segmentation, comprising the following steps:

[0296] Step 1. Use the structured light sensor to obtain t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com