Perovskite photovoltaic cells passivated with au@cds nanoparticles

A nanoparticle and photovoltaic cell technology, applied in the field of materials, can solve problems such as unfavorable carrier migration and low carrier mobility, and achieve the effects of improving battery short-circuit current and filling factor, inhibiting diffusion, and accelerating migration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

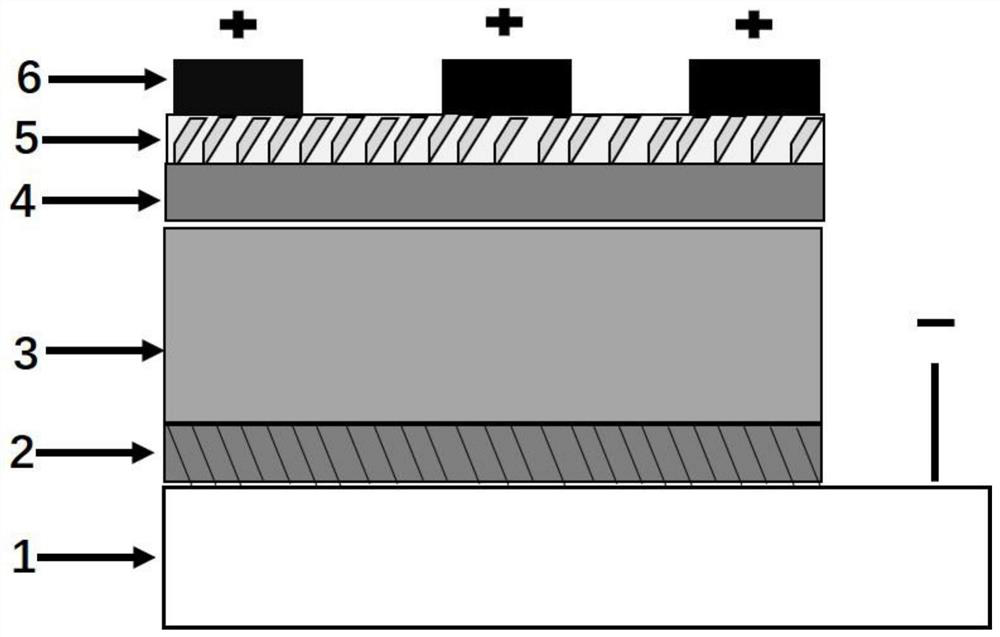

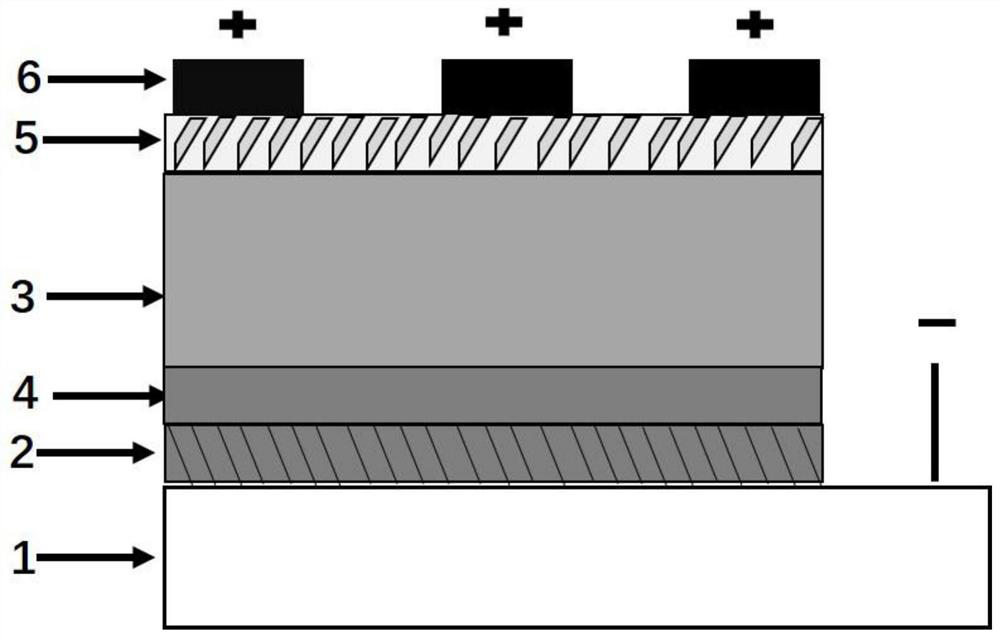

[0038] like figure 1 As shown, a planar structure perovskite photovoltaic cell includes a transparent conductive substrate, an electron transport layer, a perovskite photosensitive active layer, an interface passivation layer, a hole transport layer and a metal electrode, and its preparation method includes the following steps:

[0039] (1) Treatment of transparent conductive substrate: cleaning FTO (fluorine-doped SnO 2 ) conductive glass sheet, first soak the conductive glass sheet in a solution containing detergent (such as Libai brand liquid detergent) for 30 minutes, then repeatedly scrub and rinse with clean water; then polish with polishing powder; then separately Put it into a vessel containing deionized water, acetone and alcohol for 20 minutes respectively; finally, put it in deionized water to rinse twice, dry it with a nitrogen gun and put it in an oven to dry at 80°C;

[0040] (2) SnO 2 QD Thin Film Preparation: SnO on FTO Substrate 2 The QD film was placed in ...

Embodiment 2

[0052] like figure 1 As shown, a planar structure perovskite photovoltaic cell includes a transparent conductive substrate, an electron transport layer, a perovskite photosensitive active layer, an interface passivation layer, a hole transport layer and a metal electrode, and its preparation method includes the following steps:

[0053] (1) cleaning ITO conductive glass sheet: same as Example 1;

[0054] (2) SnO 2 Thin Film Preparation: Preparation of SnO on ITO Substrate 2 The thin film was placed in a UV-ozone cleaner, and treated with UV-ozone for 15 minutes in an atmospheric atmosphere and room temperature, and the treated SnO 2 / The ITO substrate was quickly transferred into the glove box;

[0055] (3) Preparation of perovskite photosensitive active layer: the same as in Example 1;

[0056] (4) Preparation of interface passivation layer on perovskite photosensitive film:

[0057] a. Solution preparation: The previously synthesized Au@CdS nanoparticles with Au partic...

Embodiment 3

[0063] like figure 1 As shown, a planar structure perovskite photovoltaic cell includes a transparent conductive substrate, an electron transport layer, a perovskite photosensitive active layer, an interface passivation layer, a hole transport layer and a metal electrode, and its preparation method includes the following steps:

[0064] (1) Cleaning the FTO conductive glass sheet: the same as in Example 1;

[0065] (2) SnO 2 QD film preparation: same as Example 1;

[0066] (3) Preparation of perovskite photosensitive active layer: the same as in Example 1;

[0067] (4) Preparation of interface passivation layer on perovskite photosensitive film:

[0068]a. Solution preparation: The previously synthesized Au@CdS nanoparticles with Au particle size of 30 nm and CdS coating thickness of 10 nm were dissolved in 1 ml of chlorobenzene solvent, ultrasonicated in an ultrasonic cleaner for 1 h, and the solution concentration was 0.03 mmol / mL. stand-by;

[0069] b. Preparation of i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com